C 10.12 1

C 10.12 Transportation

1

Safety regulations for transportation

m

Accidents can happen when the paver finisher and the screed are not properly pre-

pared for transportation or when transportation is carried out improperly!

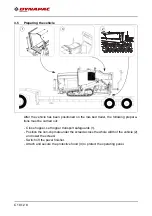

Reduce both the paver finisher and the screed to their basic widths. Remove all pro-

truding parts (such as the automatic levelling system, auger limit switches, side

shields, etc.).

Close the hopper lids and engage the hopper transport safeguards. Lift the screed

and engage the screed transport safeguards.

Pack all parts that are not permanently fixed to the paver finisher and the screed into

the appropriate boxes and into the hopper.

Close all coverings and check that they are securely seated.

In Germany, gas bottles must not be transported on the paver finisher or on

the screed.

Disconnect the gas bottles from the gas system and protect them with their caps. Use

a separate vehicle to transport them.

When loading via ramps, there is a risk that the machine will slip, tilt or overturn.

Drive carefully! Keep people away from the danger area!

Additional stipulations for transportation on public roads:

m

In Germany; caterpillar paver finishers

must not be driven as self-propelling vehi-

cles

on public roads.

Note that in other countries different regulations may apply.

The operator must be in the possession of a valid permit for vehicles of this type.

The driving lights must be properly adjusted.

Only attachments and extension parts may be transported in the hopper, no material

or gas bottles!

If necessary, the operator must be assisted by a second person when driving on pub-

lic roads – especially at road crossings and junctions.

Содержание F1200C

Страница 2: ...www dynapac com...

Страница 10: ...8...

Страница 24: ...A 2...

Страница 31: ...B 7 4 Safety devices 4 5 6 7 8 8 2 1 9 3 10...

Страница 34: ...B 10 5 2 Permissible approach angle max 15 max 10...

Страница 40: ...B 16 8 6 3 5 7 41 24 14 10 20 15 19 3 6 8 14 18 17 16 21 13 11 23 22 41 5 4 14 12 60 1 40 2 42 o...

Страница 41: ...B 17 xxxxxxxxxxxxxxxxx 32 30 31...

Страница 52: ...B 28...

Страница 74: ...C 10 12 22...

Страница 78: ...D 10 12 4 15 16 18 14 13 17 12 11 10 10 19...

Страница 80: ...D 10 12 6 15 16 18 14 13 17 12 11 10 10 19...

Страница 82: ...D 10 12 8 15 16 18 14 13 17 12 11 10 10 19...

Страница 84: ...D 10 12 10 21 20 23 22...

Страница 86: ...D 10 12 12 25 24 27 26...

Страница 88: ...D 10 12 14 25 24 27 26...

Страница 90: ...D 10 12 16 29 30...

Страница 92: ...D 10 12 18 32 31...

Страница 94: ...D 10 12 20 33...

Страница 96: ...D 10 12 22 35 34...

Страница 98: ...D 10 12 24 36 38 37...

Страница 100: ...D 10 12 26 40 39...

Страница 102: ...D 10 12 28 42 41...

Страница 104: ...D 10 12 30 44 43...

Страница 106: ...D 10 12 32 45...

Страница 108: ...D 10 12 34 51 56 58 57 59...

Страница 110: ...D 10 12 36 51 56 58 57 59...

Страница 112: ...D 10 12 38 Flame monitoring o 73 71 72 70...

Страница 114: ...D 10 12 40 77 74 75 76...

Страница 118: ...D 10 12 44 95 90 91 92 93 94...

Страница 120: ...D 10 12 46 95 90 91 92 93 94...

Страница 122: ...D 10 12 48 4 Remote control 103 104 101 106 100 102 105 107 108 109...

Страница 124: ...D 10 12 50 103 104 101 106 100 102 105 107 108 109...

Страница 126: ...D 10 12 52 103 104 101 106 100 102 105 107 108 109...

Страница 128: ...D 10 12 54 103 104 101 106 100 102 105 107 108 109...

Страница 130: ...D 10 12 56 5 Malfunctions 5 1 Error code query for engine 3 1 2...

Страница 144: ...D 30 12 12 m Tighten all assembly parts properly after setting up...

Страница 152: ...D 30 12 20...

Страница 157: ...D 40 12 5 1 3 7 8 6 6 7 7 6 2 4 9 5...

Страница 160: ...D 40 12 8 1 3 7 8 6 6 7 7 6 2 4 9 5...

Страница 163: ...D 40 12 11 1 2...

Страница 165: ...D 40 12 13 6 1 2 3 4 5...

Страница 167: ...D 40 12 15 4 6 6 6 1 2 5 3...

Страница 171: ...D 40 12 19 2 3 2 2 1 4...

Страница 173: ...D 40 12 21 1 8 9 8 8 6 4 2 3 5 7 10 13 11 12...

Страница 176: ...D 40 12 24 1 2...

Страница 178: ...D 40 12 26 1 4 5 10 10 7 3 2 9 6 8 12 10 13 14 16 15 11 4 4 11 11...

Страница 186: ...D 40 12 34...

Страница 203: ...F 2 12 1 F 2 12 Maintenance review 1 Maintenance review 8 12 4 12 5 12 3 12 7 12 6 12 11 12 100 02...

Страница 205: ...F 3 12 1 F 3 12 Maintenance conveyor 1 Maintenance conveyor...

Страница 211: ...F 4 12 1 F 4 12 Maintenance auger assembly 1 Maintenance auger assembly...

Страница 233: ...F 6 12 1 F 6 12 Maintenance hydraulic system 1 Maintenance hydraulic system...

Страница 247: ...F 7 12 1 F 7 12 Maintenance drive unit 1 Maintenance drive unit...

Страница 260: ...F 7 12 14...

Страница 261: ...F 8 12 1 F 8 12 Maintenance electrical system 1 Maintenance electrical system...

Страница 276: ...F 8 12 16...

Страница 278: ...F 11 12 2 2 7 1 3 5 6 6 4...

Страница 284: ...F 11 12 8...

Страница 285: ...F 100 1 F 100 Tests stopping 1 Tests checks cleaning stopping...

Страница 294: ...F 100 10...

Страница 296: ...www dynapac com...