D 30.12 16

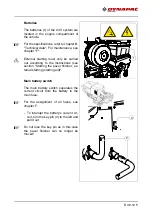

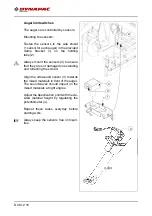

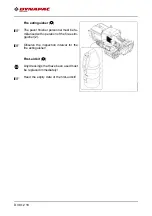

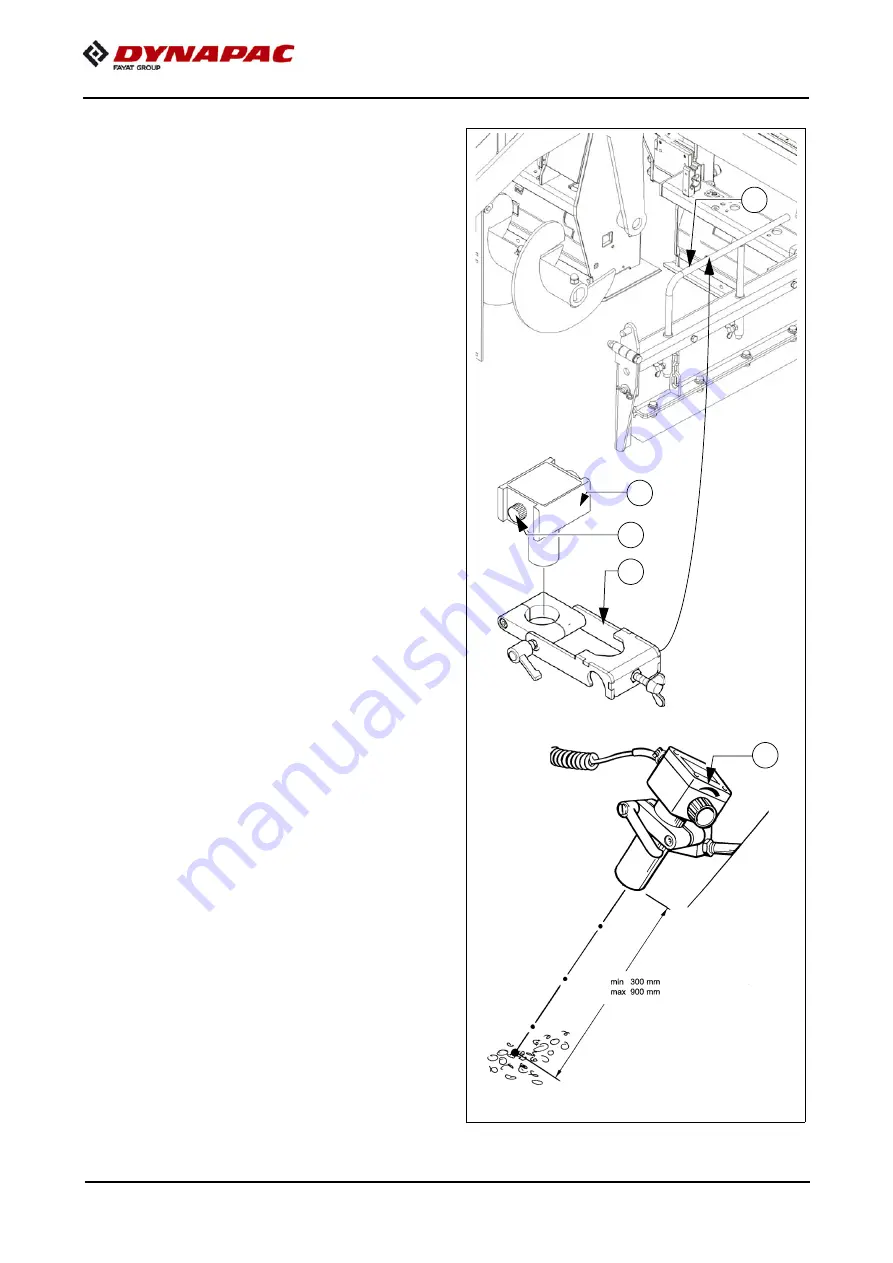

Auger limit switches

The augers are controlled by sensors.

Mounting the sensors:

Fasten the sensors to the side shield

(1 sensor for each auger) in the provided

clamp bracket (1) on the holding

tube (2).

m

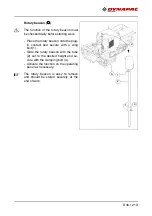

Always mount the sensors (3) to ensure

that they are not damaged on extending

and retracting the screed.

Align the ultrasound sensor (3) towards

the mixed materials in front of the auger.

The sound waves should impact on the

mixed materials at right angles.

Adjust the deactivation point with the de-

sired material height by regulating the

potentiometer (4).

Repeat these tasks everyday before

starting work.

A

Always keep the sensors free of impuri-

ties.

3

2

1

3

4

Содержание F1200C

Страница 2: ...www dynapac com...

Страница 10: ...8...

Страница 24: ...A 2...

Страница 31: ...B 7 4 Safety devices 4 5 6 7 8 8 2 1 9 3 10...

Страница 34: ...B 10 5 2 Permissible approach angle max 15 max 10...

Страница 40: ...B 16 8 6 3 5 7 41 24 14 10 20 15 19 3 6 8 14 18 17 16 21 13 11 23 22 41 5 4 14 12 60 1 40 2 42 o...

Страница 41: ...B 17 xxxxxxxxxxxxxxxxx 32 30 31...

Страница 52: ...B 28...

Страница 74: ...C 10 12 22...

Страница 78: ...D 10 12 4 15 16 18 14 13 17 12 11 10 10 19...

Страница 80: ...D 10 12 6 15 16 18 14 13 17 12 11 10 10 19...

Страница 82: ...D 10 12 8 15 16 18 14 13 17 12 11 10 10 19...

Страница 84: ...D 10 12 10 21 20 23 22...

Страница 86: ...D 10 12 12 25 24 27 26...

Страница 88: ...D 10 12 14 25 24 27 26...

Страница 90: ...D 10 12 16 29 30...

Страница 92: ...D 10 12 18 32 31...

Страница 94: ...D 10 12 20 33...

Страница 96: ...D 10 12 22 35 34...

Страница 98: ...D 10 12 24 36 38 37...

Страница 100: ...D 10 12 26 40 39...

Страница 102: ...D 10 12 28 42 41...

Страница 104: ...D 10 12 30 44 43...

Страница 106: ...D 10 12 32 45...

Страница 108: ...D 10 12 34 51 56 58 57 59...

Страница 110: ...D 10 12 36 51 56 58 57 59...

Страница 112: ...D 10 12 38 Flame monitoring o 73 71 72 70...

Страница 114: ...D 10 12 40 77 74 75 76...

Страница 118: ...D 10 12 44 95 90 91 92 93 94...

Страница 120: ...D 10 12 46 95 90 91 92 93 94...

Страница 122: ...D 10 12 48 4 Remote control 103 104 101 106 100 102 105 107 108 109...

Страница 124: ...D 10 12 50 103 104 101 106 100 102 105 107 108 109...

Страница 126: ...D 10 12 52 103 104 101 106 100 102 105 107 108 109...

Страница 128: ...D 10 12 54 103 104 101 106 100 102 105 107 108 109...

Страница 130: ...D 10 12 56 5 Malfunctions 5 1 Error code query for engine 3 1 2...

Страница 144: ...D 30 12 12 m Tighten all assembly parts properly after setting up...

Страница 152: ...D 30 12 20...

Страница 157: ...D 40 12 5 1 3 7 8 6 6 7 7 6 2 4 9 5...

Страница 160: ...D 40 12 8 1 3 7 8 6 6 7 7 6 2 4 9 5...

Страница 163: ...D 40 12 11 1 2...

Страница 165: ...D 40 12 13 6 1 2 3 4 5...

Страница 167: ...D 40 12 15 4 6 6 6 1 2 5 3...

Страница 171: ...D 40 12 19 2 3 2 2 1 4...

Страница 173: ...D 40 12 21 1 8 9 8 8 6 4 2 3 5 7 10 13 11 12...

Страница 176: ...D 40 12 24 1 2...

Страница 178: ...D 40 12 26 1 4 5 10 10 7 3 2 9 6 8 12 10 13 14 16 15 11 4 4 11 11...

Страница 186: ...D 40 12 34...

Страница 203: ...F 2 12 1 F 2 12 Maintenance review 1 Maintenance review 8 12 4 12 5 12 3 12 7 12 6 12 11 12 100 02...

Страница 205: ...F 3 12 1 F 3 12 Maintenance conveyor 1 Maintenance conveyor...

Страница 211: ...F 4 12 1 F 4 12 Maintenance auger assembly 1 Maintenance auger assembly...

Страница 233: ...F 6 12 1 F 6 12 Maintenance hydraulic system 1 Maintenance hydraulic system...

Страница 247: ...F 7 12 1 F 7 12 Maintenance drive unit 1 Maintenance drive unit...

Страница 260: ...F 7 12 14...

Страница 261: ...F 8 12 1 F 8 12 Maintenance electrical system 1 Maintenance electrical system...

Страница 276: ...F 8 12 16...

Страница 278: ...F 11 12 2 2 7 1 3 5 6 6 4...

Страница 284: ...F 11 12 8...

Страница 285: ...F 100 1 F 100 Tests stopping 1 Tests checks cleaning stopping...

Страница 294: ...F 100 10...

Страница 296: ...www dynapac com...