B 4

Hydraulic system:

The diesel engine drives the hydraulic pumps for all main paver

finisher drives via the attached distribution gear and its auxiliary drive shafts.

Travel drive:

The continuously adjustable travel drive pumps are connected to the

travel drive engines by means of high pressure hydraulic hoses.

These hydraulic motors drive the caterpillar chains via planetary gears that are

mounted directly inside the drive units of the caterpillar chains.

Steering system/operator's platform:

The independent hydrostatic travel drives al-

low the paver finisher to be turned on the spot.

The adjustable synchronisation, controlled from the operating panel, ensures that the

paver finisher runs straight ahead.

Push roller crossbar:

The push rollers for material trucks are fastened to a cross bar

that is pivoted at its centre.

This crossbar allows different distances to the rear wheels of material trucks to be

compensated. The paver finisher thus deviates less from its course and paving in

curves is made easier.

The push rollers and the hopper can be swivelled up together to reduce the

transport width.

Material compartment (hopper):

The hopper inlet is equipped with a conveyor sys-

tem that empties the hopper and transfers the material to the auger.

The hopper can hold approx. 5.0 t.

To facilitate emptying and to improve material transfer, each of the lateral covers of

the hopper can be hydraulically moved.

Material transfer:

The paver finisher has a conveyor that brings the material from the

hopper to the distribution augers.

By scanning the filling height during the paving procedure, the transfer amount is reg-

ulated fully automatically.

Augers:

The augers are driven and actuated independently from the conveyors. The

left-hand and the right-hand half of the auger can be controlled separately. The drive

system is fully hydraulic.

The conveying direction can be changed towards the centre or towards the outside.

This ensures that there is always a sufficient supply of material even if an excessive

amount of material is required at one side. The auger speed is controlled by sensors

that monitor the material flow.

Height adjustment and extension of augers:

Height adjustment and extension of

augers ensure optimum adaptation to a wide range of paving thicknesses and widths.

Содержание F1200C

Страница 2: ...www dynapac com...

Страница 10: ...8...

Страница 24: ...A 2...

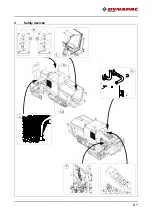

Страница 31: ...B 7 4 Safety devices 4 5 6 7 8 8 2 1 9 3 10...

Страница 34: ...B 10 5 2 Permissible approach angle max 15 max 10...

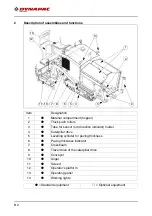

Страница 40: ...B 16 8 6 3 5 7 41 24 14 10 20 15 19 3 6 8 14 18 17 16 21 13 11 23 22 41 5 4 14 12 60 1 40 2 42 o...

Страница 41: ...B 17 xxxxxxxxxxxxxxxxx 32 30 31...

Страница 52: ...B 28...

Страница 74: ...C 10 12 22...

Страница 78: ...D 10 12 4 15 16 18 14 13 17 12 11 10 10 19...

Страница 80: ...D 10 12 6 15 16 18 14 13 17 12 11 10 10 19...

Страница 82: ...D 10 12 8 15 16 18 14 13 17 12 11 10 10 19...

Страница 84: ...D 10 12 10 21 20 23 22...

Страница 86: ...D 10 12 12 25 24 27 26...

Страница 88: ...D 10 12 14 25 24 27 26...

Страница 90: ...D 10 12 16 29 30...

Страница 92: ...D 10 12 18 32 31...

Страница 94: ...D 10 12 20 33...

Страница 96: ...D 10 12 22 35 34...

Страница 98: ...D 10 12 24 36 38 37...

Страница 100: ...D 10 12 26 40 39...

Страница 102: ...D 10 12 28 42 41...

Страница 104: ...D 10 12 30 44 43...

Страница 106: ...D 10 12 32 45...

Страница 108: ...D 10 12 34 51 56 58 57 59...

Страница 110: ...D 10 12 36 51 56 58 57 59...

Страница 112: ...D 10 12 38 Flame monitoring o 73 71 72 70...

Страница 114: ...D 10 12 40 77 74 75 76...

Страница 118: ...D 10 12 44 95 90 91 92 93 94...

Страница 120: ...D 10 12 46 95 90 91 92 93 94...

Страница 122: ...D 10 12 48 4 Remote control 103 104 101 106 100 102 105 107 108 109...

Страница 124: ...D 10 12 50 103 104 101 106 100 102 105 107 108 109...

Страница 126: ...D 10 12 52 103 104 101 106 100 102 105 107 108 109...

Страница 128: ...D 10 12 54 103 104 101 106 100 102 105 107 108 109...

Страница 130: ...D 10 12 56 5 Malfunctions 5 1 Error code query for engine 3 1 2...

Страница 144: ...D 30 12 12 m Tighten all assembly parts properly after setting up...

Страница 152: ...D 30 12 20...

Страница 157: ...D 40 12 5 1 3 7 8 6 6 7 7 6 2 4 9 5...

Страница 160: ...D 40 12 8 1 3 7 8 6 6 7 7 6 2 4 9 5...

Страница 163: ...D 40 12 11 1 2...

Страница 165: ...D 40 12 13 6 1 2 3 4 5...

Страница 167: ...D 40 12 15 4 6 6 6 1 2 5 3...

Страница 171: ...D 40 12 19 2 3 2 2 1 4...

Страница 173: ...D 40 12 21 1 8 9 8 8 6 4 2 3 5 7 10 13 11 12...

Страница 176: ...D 40 12 24 1 2...

Страница 178: ...D 40 12 26 1 4 5 10 10 7 3 2 9 6 8 12 10 13 14 16 15 11 4 4 11 11...

Страница 186: ...D 40 12 34...

Страница 203: ...F 2 12 1 F 2 12 Maintenance review 1 Maintenance review 8 12 4 12 5 12 3 12 7 12 6 12 11 12 100 02...

Страница 205: ...F 3 12 1 F 3 12 Maintenance conveyor 1 Maintenance conveyor...

Страница 211: ...F 4 12 1 F 4 12 Maintenance auger assembly 1 Maintenance auger assembly...

Страница 233: ...F 6 12 1 F 6 12 Maintenance hydraulic system 1 Maintenance hydraulic system...

Страница 247: ...F 7 12 1 F 7 12 Maintenance drive unit 1 Maintenance drive unit...

Страница 260: ...F 7 12 14...

Страница 261: ...F 8 12 1 F 8 12 Maintenance electrical system 1 Maintenance electrical system...

Страница 276: ...F 8 12 16...

Страница 278: ...F 11 12 2 2 7 1 3 5 6 6 4...

Страница 284: ...F 11 12 8...

Страница 285: ...F 100 1 F 100 Tests stopping 1 Tests checks cleaning stopping...

Страница 294: ...F 100 10...

Страница 296: ...www dynapac com...