5

Maintenance Manual for DUKE TSC Proofer

Oven with Touch Screen Controls

• This unit is not to be operated by children, unskilled or untrained persons, or persons with insufficient

mental or physical capabilities.

• Turn off external mains supply disconnect and allow unit to cool down before servicing or performing

maintenance.

• The procedures in this manual may include the use of chemical products. You must read the Material

Safety Data Sheets before using any of these products.

• Properly rated all poles mains protection and earthing compliance with local electric codes are required

for safe operation of this unit.

• Water supply connections to the unit must comply with local plumbing code and/or standards.

• Disposal of the unit must be in accordance with local environmental codes and/or any other applicable

codes.

Lamp(s) inside the LCD display in this product contain mercury and must be recycled or

•

disposed of according to local, state or federal laws.

•

sAve these instructions

iMPortAnt sAfetY instructions (continued)

Hg

Technical Description and Application Notes for TSC Proofer Oven Backflow Preventer Assembly

This equipment is intended to be connected to a

potable water supply system under pressure and is

to be installed with adequate backflow protection

to comply with all applicable federal, state, and

local codes.

Water supply pressure for proper operation shall be:

Minimum 40 PSIG(275 KPa)

Maximum 65 PSIG(448 KPa)

measured at water line inlet to the equipment.

If so equipped, regular maintenance is required to

replace the water filter cartridge at least once per

year, and to clean the inlet water screen at least

once per year. Consult state/local codes for any

additional requirements.

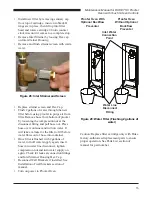

INSTALLATION OF WATER FILTER

Install new filter by removing sanitary cap from top

of cartridge, insure two black O-rings are in place,

then lift up into filter head and rotate cartridge

1/4 turn counter clockwise until it comes to a complete

stop. Flush 2 gallons (5.6 Liters) of water through the

new filter before using proofer to purge air from filter.

Remove hose from bottom of proofer by loosening

the compression nut at the disconnect fitting

and pull hose out. Place hose over container and

turn on water. It will take a minute for the filter

to fill before water flows out of hose into container.

once filter is flushed with 2 gallons (5.6 Liters) of water,

turn off water supply again, insert hose into water line

disconnect, tighten compression nut and turn

water supply on again. Check for leaks at

connection fittings.

Patent(s) Pending

Check with your local authority having jurisdiction

regarding approvals for connecting the Duke TSC

Proofer Oven to a potable water supply before

making any plumbing connections. Plumbing

code requirements vary, but Duke has made a kit

(P/N 600187) available (or installed as a factory

option) to add a backflow prevention device to

protect water supply systems by preventing the

reverse flow of non-potable water into the potable

domestic water system. The device consists of

two independently acting check valves, internally

force-loaded to a normally closed position

and designed/constructed to operate under

intermittent or continuous pressure conditions.

The two main components of the Duke backflow

preventer system are:

Dual Check Valve type backflow preventer

•

that conforms to ANSI/ASSE standard #1024

and is CSA standard B64.6 certified.

Inlet water strainer equipped with 100-mesh

•

screen and installed up stream of the backflow

preventer. The screen is conveniently located

on the rear panel of the proofer, below the

backflow preventer, for easy access during

cleaning/replacement.