24

ENGINE INSTRUCTION MANUAL

9/235HA, 10/215HA

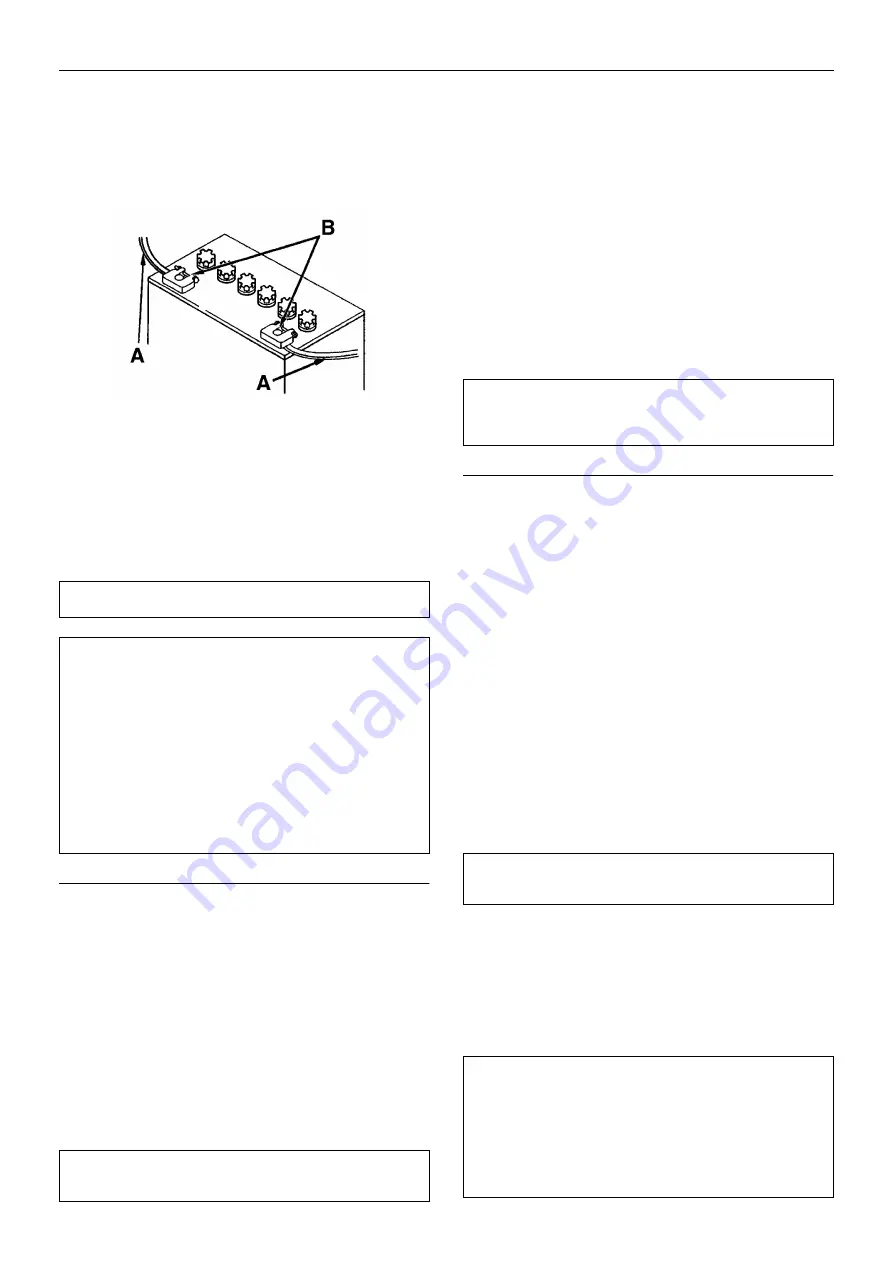

Battery cable connection

Check the battery cable connections for looseness or corrosion. A

loosened cable connection will result in hard engine starting or

insufficient battery charge. The battery cables must be tightened

securely. Never reverse “+” and “-” terminals when reconnecting

cables after disconnection. Even a short period of reverse connection

will damage the electrical parts.

Fig. 5

A. Battery cable

B. Connection

Battery electrolyte level

The amount of electrolyte in the batteries will be reduced after repeated

discharge and recharge. Check the electrolyte level in the batteries,

replenish with a commercially available electrolyte such as distilled

water, if necessary. The battery electrolyte level checking procedure

will vary with battery type.

CHECKS AND OPERATION AFTER START-UP

Check after the engine start-up

Check the following items in the engine warming-up operation:

•

Engine oil pressure -

The engine oil pressure gauge readings

(where fitted) may vary depending on ambient temperature and

type of oil. The gauge should register around 55 to 85 psi in the

warming-up period.

•

Engine noise and exhaust smoke color -

Listen to the engine

and, if any abnormal noise is heard, check to determine the cause.

Check the fuel combustion condition by observing the exhaust

smoke color. The exhaust smoke color after engine warm-up and at

no-load condition should be colorless or light blue.

Black or white smoke indicates incorrect combustion.

Leakage in the systems

Check the following items:

•

Lubrication oil leakage -

Check the engine for oil leaks, paying

particular attention to oil filter and oil pipe joints.

•

Fuel leakage -

Check the fuel injection pump, fuel lines and fuel

filter for leakage.

•

Coolant leakage -

Check the radiator and water pump hose

connections and the water drain cock on the cylinder block for

leakage.

•

Exhaust smoke or gas leakage

Checking coolant level

The coolant level could drop because any mixed air is expelled in about

5 minutes after the engine started.

Stop the engine, remove radiator cap, and add coolant.

OPERATION AND CARE OF A NEW ENGINE

Your engine is carefully tested and adjusted in the factory, however,

further run-in is necessary. Avoid any harsh engine operation within the

initial 100 operating hours.

Do not operate the unit at full load until the engine is warmed-up.

Do not allow the engine to run unloaded for extended periods so as to

minimise the risk of cylinder bore glazing.

During operation, pay attention to the following points if the engine

shows any sign of abnormalities:

(1) Engine Oil Pressure -

The engine oil pressure is monitored by a

switch that will stop the engine if the pressure falls below a pre-set

value.

If the oil pressure gauge shows below 30 psi or if the reading fluctuates

continually, stop the engine and check the oil level. If the level is

correct, contact your local Doosan branch or dealer to establish the

cause.

(2) Coolant Temperature -

The engine performance will be adversely

affected if engine coolant temperature is too hot or too cold. The

normal coolant temperature is 75 to 85°C (167 to 185°F).

Overheating

If the Engine Coolant Temperature gauge (where fitted) shows an

overheat condition, or you have reason to suspect the engine may be

overheating, take the following steps:

•

Close the service valve to reduce the load.

•

Let the engine run at normal idle speed for two or three minutes. If

the engine coolant temperature does not start to drop, turn off the

engine and proceed as follows:

NOTE: Do not replenish with dilute sulfuric acid in the daily

service.

CAUTION: When inspecting the batteries, be sure to stop the

engine first.

As dilute sulphuric acid is used as electrolyte, be careful not to

contaminate your eyes, hands, clothes, and metals with the

electrolyte. If it gets in your eye, wash with a large amount of

water at once, then seek medical advice.

As highly flammable hydrogen gas is released from the

batteries, do not create a spark or allow any naked flame near

the batteries.

When handling such metallic articles as tools near the batteries,

be sure not to contact the “+” terminal because the compressor

body is “-” and a dangerous short circuit might result.

When disconnecting the terminals, start with “-” terminal. When

connecting them, connect the “-” terminal last.

NOTE: After start-up from cold the engine might be noisier and

the exhaust smoke color darker than when it has warmed up.

However this condition will disappear after warm up.

CAUTION: Hot steam can rush out and you could get burnt if the

radiator cap is removed when the engine is hot. Cover the

radiator cap with a thick cloth and loosen the cap slowly to

reduce the pressure, then remove the cap.

CAUTION: If you see or hear escaping steam or have other

reason to suspect there is a serious overheat condition, stop the

engine immediately.

CAUTION: To help avoid being burned:

Do not open the canopy or door if you see or hear steam or

engine coolant escaping. Wait until no steam or engine coolant

can be seen or heard before opening the engine canopy or door.

Do not remove the radiator filler cap if the engine coolant in the

reserve tank is boiling. Also do not remove the radiator filler cap

while the engine and radiator are still hot. Scalding fluid and

steam can be blown out under pressure if either cap is taken off

too soon.

Содержание 10/215HA

Страница 2: ......

Страница 8: ...6 DECALS 9 235HA 10 215HA Engine oil drain...

Страница 50: ...48 MACHINE SYSTEMS 9 235HA 10 215HA...

Страница 51: ...MACHINE SYSTEMS 49 9 235HA 10 215HA...

Страница 52: ...50 MACHINE SYSTEMS 9 235HA 10 215HA...

Страница 53: ...MACHINE SYSTEMS 51 9 235HA 10 215HA...

Страница 54: ...52 MACHINE SYSTEMS 9 235HA 10 215HA...

Страница 55: ...MACHINE SYSTEMS 53 9 235HA 10 215HA...

Страница 61: ...OPTIONS 59 9 235HA 10 215HA WATER SEPARATOR MAINTENANCE FIGURE 1 FIGURE 2 FIGURE 3 FIGURE 4 FIGURE 5 FIGURE 6...

Страница 67: ......

Страница 68: ...Doosan Bobcat EMEA s r o U Kodetky 1810 263 12 Dob Czech Republic www doosanportablepower eu...