(Bulletin R61/7A continued)

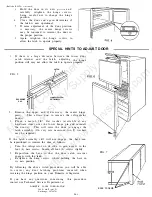

NOTE: The cooling units currently being used

are specially designed to prevent overheating of

the boiler tube even when operated out-of-level.

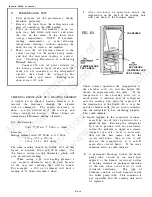

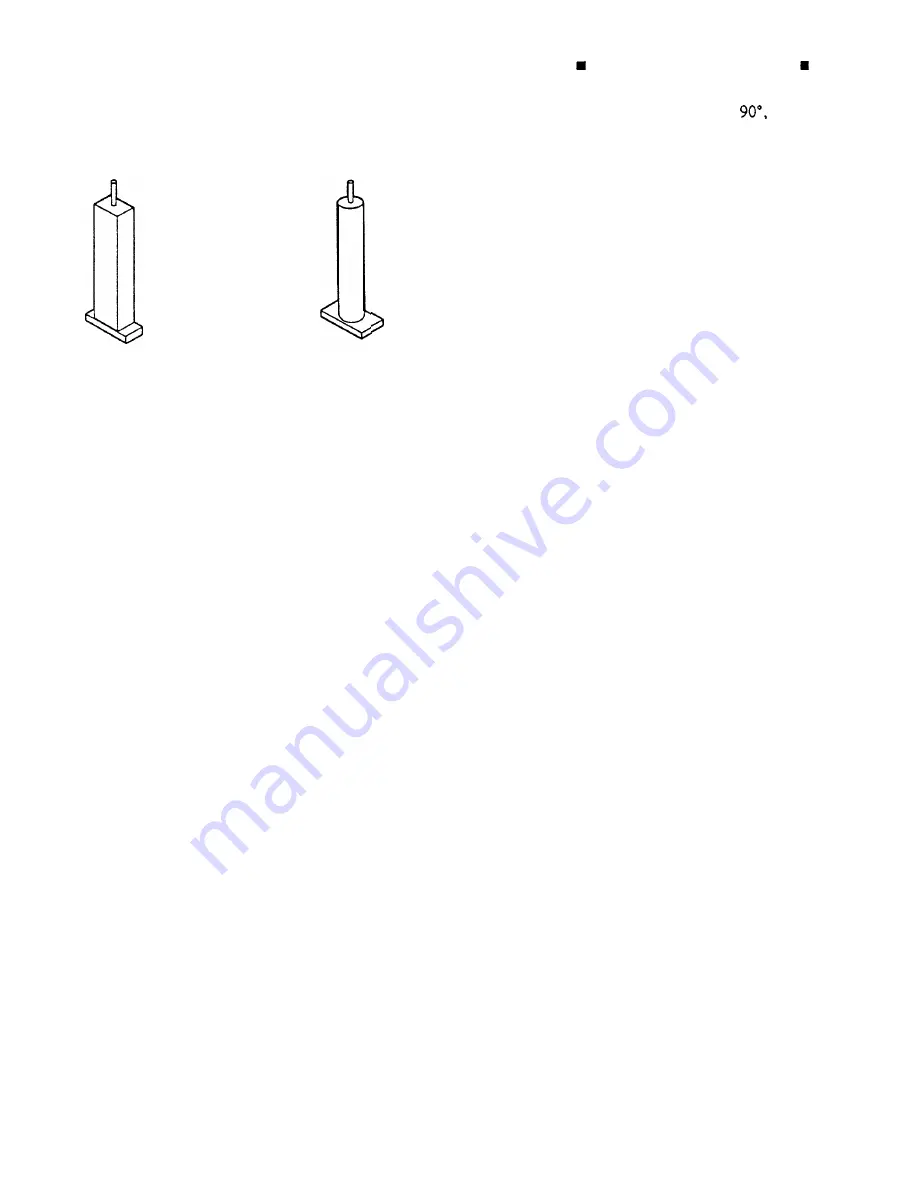

This special design can be identified by the

round insulation box around the boiler, rather

than the square-cornered box used on older units.

FIG. B2

Older Style Current Style

Boiler Enclosure Boiler Enclosure

Blockage symptoms on the newer cooling units

almost always, indicate trapped liquid in the

evaporator, which can be corrected by proper

leveling and allowing the cooling unit to cool

off before restarting.

6. If the temperatures are satisfactory in Step

5, continue operating the unit, with power

directly to the heating element, for a total

of 10-12 h o u r s . The doors must be kept

closed for this entire period.

7. If the temperature is within the previously

mentioned guidelines the problem is not in

the cooling unit. See Section

II. OTHER

C A U S E S

for additional items that could be

causing a loss of cooling.

8.

If the temperature in the food compartment

is higher than the acceptable limit, the

cooling unit is probably defective. If you

are still in question as to the performance

of the cooling unit, please contact our Techni-

cal Service Department (219) 463-4858. See

the next paragraph before changing the

cooling unit.

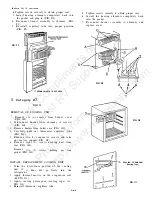

9. The importance of adequate air flow across

the cooling unit cannot be emphasized too

much. A minor restriction in the venting

system will not create a problem on cooler

days - the available air flow will still provide

adequate cooling due to the lower temperature.

However, on a hot day (90” or more) even

a minor restriction will cause overheating of

the cooling unit and the cooling process will

slow down or stop.

ONE LASTCHECK

If the previously mentioned test was performed

in air temperatures above

and the

temperature in the refrigerator is above the

acceptable ranges, it may indicate a restricted

air flow. To make sure there is no problem

with the venting system repeat the perfor-

mance test with the refrigerator removed

from its installed location and placed on

the floor, or in your service shop. If the

second test indicates satisfactory performance,

re-check the venting and installation.

PART II. OTHER CAUSES FOR

LOSS OF COOLING

If the previously mentioned performance test

shows that the refrigerator is working satisfac-

torily, and the customer still experiences loss of

cooling, the following items need to be considered:

1. Make sure the customer is using the refriger-

ator properly. The cooling capacity of the

absorption refrigerator is usually much lower

than the refrigerator the customer has in his

home, so the customer should be advised to

follow the instructions for proper use in his

Owner’s Manual.

A.

B.

C.

D.

Start the refrigerator the day before it

is to be filled with food.

When the refrigerator is being filled

when preparing for a trip, the food

should be pre-cooled, and frozen foods

should be pre-frozen, before placing

them in the refrigerator. Ice making

should be avoided until the refrigerator

has cooled the lower compartment to the

desired temperature.

Air circulation within the food compart-

ment is important for proper cooling.

DO NOT place paper on the shelves or

over-fill the compartment with large

cartons, etc.

Do not put hot food in the refrigerator.

Allow it to cool in room air first.

D-9-13

Manual

Compliments

of

Northwest

RV

Supply

Printed

From

http://www.nwrvsupply.com