U 3)

As

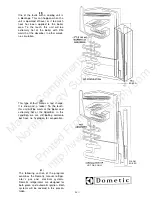

this process continues, the ammonia and

hydrogen vapors become intermixed and flow

downward into the absorber vessel. As the

ammonia vapor comes in close contact to the

liquid ammonia solution in the absorber vessel,

the ammonia is absorbed into the liquid

solution, allowing the hydrogen vapor to rise up

through the absorber coils. After this absorption

process, the vapor consists of mostly hydrogen

with

some traces of ammonia.

-------

(14)

To remove the remaining amounts of ammonia

vapor still present in the hydrogen, a

continuous flow of weak ammonia solution is

fed, by gravity, to the top of the absorber coil

from the boiler. As this weak ammonia solution

flows downward through the absorber, it

absorbs the ammonia vapor from the mixture,

allowing the hydrogen vapor to rise through the

absorber coil and return to the evaporator. With

the hydrogen returned to the evaporator and

the ammonia remixed into solution in the

absorber vessel, the cooling process can

continue.

(15)

Now that we have a basic understanding of

proper cooling unit flow and operation, let’s

take a step-by-step look at the three require-

ments for proper cooling unit operation. Please

note it is essential that these three requirements

be diagnosed before attempting to diagnose

the cooling unit. A problem with leveling, heat

input or ventilation may lead you to think that

the cooling unit is faulty, when actually it is not.

This causes an increased expense to you, the

customer, and valuable shop time is wasted

because of incorrect diagnosis, By following

and checking the three unit requirements, costly

diagnostic errors can be eliminated.

--- __------

THREE REQUIREMENTS

FOR PROPER OPERATION

1. Level

2. Air Flow (Ventilation)

3. Heat

D-6-6

Manual

Compliments

of

Northwest

RV

Supply

Printed

From

http://www.nwrvsupply.com