Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.00: 10 Sept, 2021

Page

6 of 46

CONNECTION & OPERATION

CAUTION

: Never connect or disconnect parts of the display system when the system is powered up as this may cause serious

damage.

CONNECTION

Connection and usage is quite straight forward (it is useful to have the relevant connection diagram available at this time):

1. LCD panel & Inverter:

Connect the inverter (if it is not built-in the panel) to the CCFT lead connector of the LCD panel.

2.

LVDS type panel

s

:

The controller board has the built-in LVDS transmitter driver. Plug the LVDS cable to J3. Insert the

panel end of the cable the LCD panel connector.

3. Inverter & Controller:

Plug the inverter cable to CNB1 and CNA1 (if necessary). Plug another end to the connector on

the inverter.

4.

Function switch & Controller:

Plug the OSD switch mount cable to CNC1 on the controller board and another to the

OSD switch mount.

5.

LED & Controller:

Plug in a 3-way with dual color LED to connector LED1 on the controller board.

6.

IR & Controller:

Plug in a 3-way with IR sensor to connector IR1 on the controller board.

7.

Jumpers & Switches:

Check all jumpers and switches (SW3, SW4) are set correctly. Details referring the connection

diagram (a separate document) or the jumpers and switches setting table (in the following section).

8.

Jumpers & Inverter & Panel voltage:

Particularly pay attention to the settings of JA3, JA5, JA6, JB2 and JB3. JB2 &

JB3 are used for inverter control (read inverter specification and information on the jumper table to define the correct

settings). JA3 & JA5 & JA6 is used for panel voltage input (read panel specification and information on the jumper table

to define the correct settings).

9.

Input signal cable & Controller:

Plug the corresponding signal input to the connector on the controller board.

10. SDI input cable :

Plug the coaxial cable to connector J4 on the controller board for SDI input cable. Plug another coaxial

cable to J5 for re-clock loop out. Recommend to connect less than 100 meter in good co-axial cable (e.g Belden 1694A)

between DV devices.

11. Power supply & Controller:

Plug the DC 12V/24V power in to the connector PP5 or PP2. You can consider to use

DigitalView mating power cable P/N 426013800-3, 160mm for PP5 connection.

11. External panel power input :

Plug power cable : P/N 426013700-3 for external panel power input (3.3 (max 7A) / 5V

(max 7A) / 10V (max 5A) / 12V (max 5A) / 18V (max3.5))

12.

Power on:

Switch on the controller board and panel by using the OSD switch mount.

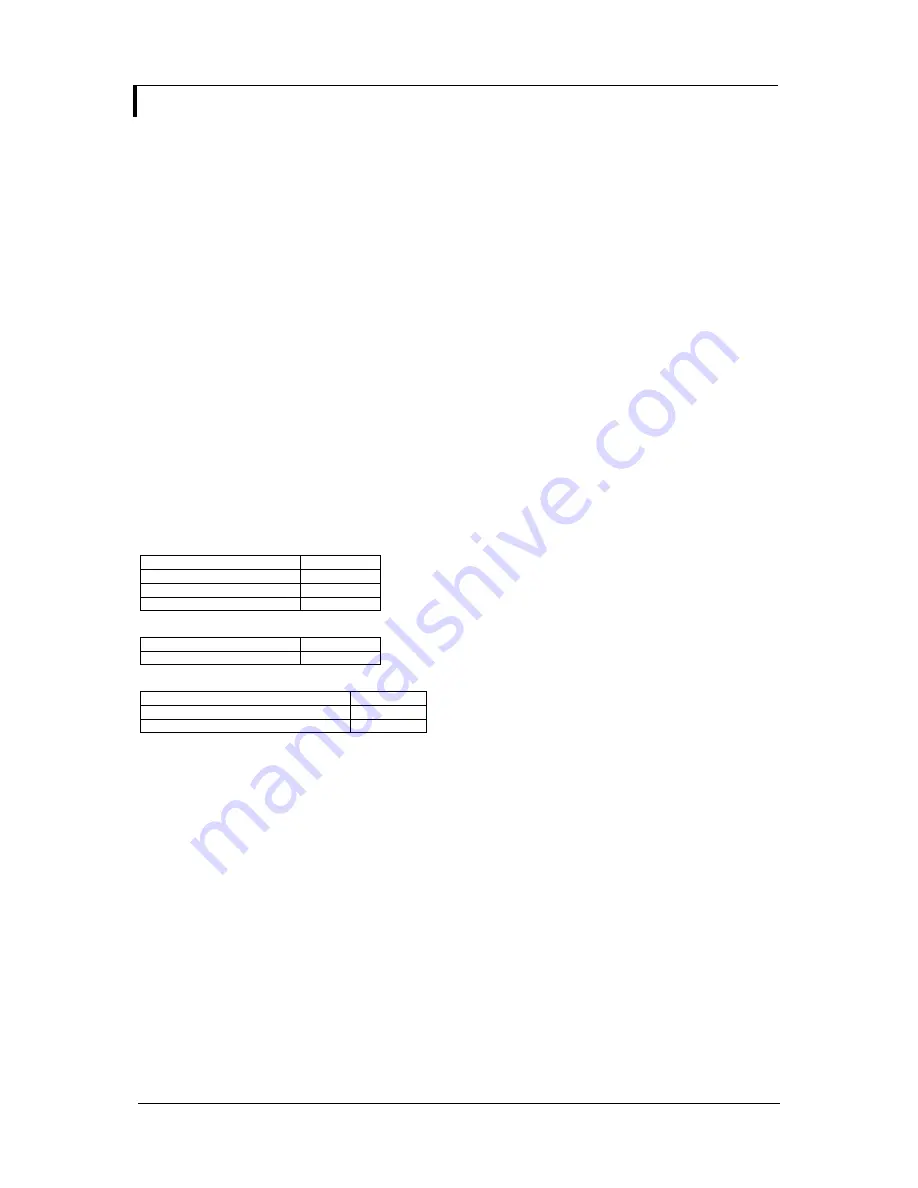

Controller LED status (LED1/LED1A) :

State

LED color

No signal & backlight off

RED

No signal & backlight on

ORANGE

With signal & backlight on

GREEN

LED status (LED3) :

LED color

Controller power ON

Green

Controller LED status (LED6) :

Panel power output status

LED color

10V / 12V / 18V panel power output

GREEN

3.3V / 5V panel power output

RED

General:

•

If you are using supplied cables & accessories, ensure they are correct for the model of panel and controller.

•

If you are making your own cables & connectors refer carefully to both the panel & inverter specifications and the section

in this manual, “Connectors, Pinouts & Jumpers” to ensure the correct pin to pin wiring.

PC SETTINGS

The controller has been designed to take a very wide range of input signals however to optimize the PC’s graphics

performance we recommend choosing 60Hz vertical refresh rate – this will not cause screen flicker.

OPERATION

Once the system has been connected and switched on there are a number of functions available to adjust the display

image as summarized in the following sections. The settings chosen will be saved for each mode independently.