15

English

16. Press the ON/STOP button

28

for 2 seconds. The green

READY light will illuminate. The yellow WATER FLOW light

should also illuminate to verify the water is connected

properly and turned on.

Fig. R

28

17. When the green system ready light illuminates, squeeze the

spray gun trigger to start the engine. After squeezing the

spray gun trigger it will take approximately 3 seconds for

engine to start. After the engine has started, the water flow

will begin and the yellow water flow light will illuminate.

See the

PREssUREADY

® Fault Codes Table

in the

Troubleshooting

section

for more information.

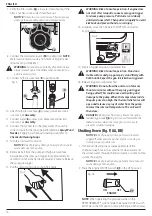

nOTE:

The spray gun is equipped with a spring loaded trigger

lock

16

. Manually release trigger lock as shown in Fig. S.

Fig. S

16

WARNING:

Risk of unsafe operation. Stand on a stable

surface and grip spray gun/wand firmly with both hands.

Expect the spray gun/wand to kickback when triggered.

18. When spray gun trigger is released, water flow will stop

immediately and the engine will shut off in approximately

10 seconds. Ensure spring loaded trigger lock is moved

forward into the locked position.

19. To restart pressure washer, manually release trigger lock and

squeeze the spray gun trigger and the engine will restart.

Note that it will take approximately 3 seconds for engine to

start after squeezing spray gun trigger. After the engine has

started, the water flow will begin.

DANGER:

Risk of injury from spray. Ensure the spring

loaded trigger lock

16

is moved forward to the locked

position, when the spray gun is not in use to prevent

accidental spraying.

Alternate Manual Mode

Start-up Procedure

(Without Battery)

(Fig. B, T–Z)

1. In a well-ventilated outdoor area, add fresh, high-quality,

unleaded petrol with a pump octane rating of 86 or

higher. Do not overfill. Wipe up spilled fuel before starting

the engine. Refer to engine instruction manual for

correct procedure.

IMPORTANT: Ethanol Shield™ (sold separately) is a fuel

stabilizer that helps eliminate and prevent ethanol related

problems in power equipment. Follow the instructions on

the container and add to the petrol.

NOTICE:

Use of fuels with greater than 10% ethanol are

not approved for use in this product per EPA regulations

and will damage the unit and void the warranty.

2. Check engine oil level. Refer to the engine instruction

manual for correct procedure.

NOTICE:

The engine is shipped without oil. Before starting

engine, add the oil provided. Damage to the engine will

occur if the engine is run without oil, this damage will not

be covered under warranty.

3. Place the engine ON/OFF switch

27

in the ON position.

OFF

On

Fig. T

27

EnginE

4. Place the fuel valve lever in the ON position.

Fig. U

5. Move the choke to the CLOSED Position.

Fig. V

6. Connect the water hose to the cold water source. Turn the

cold water source on to remove all air from the hose and

flush any debris. When a steady stream of water is present,

turn the cold water source off.

Содержание DCB107

Страница 1: ...145mm 210mm ...

Страница 2: ...B Copyright DeWALT English original instructions 1 ...

Страница 26: ...24 ...

Страница 27: ...25 ...

Страница 28: ...7113784 03 20 AUST 1800 841 749 NZ 0800 467 813 ...