30

EN

1x

3x

C

1x

D

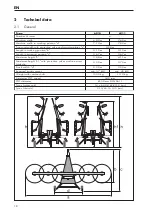

B – rotary gear:

A – main gear:

C – hinge pin, double

universal joint:

D - hinge pin, single

universal joint:

5.4

Lubrication

The lubrication diagram indicates all lubrication points

(fig. 5-1 / fig. 5-2).

You can achieve a long service life for your machine

by observing all maintenance and lubrication intervals

stated in these instructions.

Use lubricating grease K2 k in acc. with DIN 51825,

e.g. "Deutzer Öl", "HFL 300 W", or "Shell Retinax A".

Clean the lubrication nipples and application nipples

of the grease gun before applying the grease gun.

Lubrication points:

Lubrication points:

Lubrication points:

Lubrication points:

Lubrication points:

z

Cardan shaft, pivot pin, all joints and contact points

z

Universal joints of the rotary unit drive hinge

pin

Check the oil level of the gears with the implement in a

horizontal position.

z

Main gear (A):

1.1l / SAE 90 API-GL-4

z

Rotary gear (B):

0.32l / SAE 90 API-GL-4

E - pivot pin:

Содержание CondiMaster 6831

Страница 2: ......

Страница 4: ...2 EN...

Страница 13: ...11 EN 6 Keep clear of the swivel area of the implement...

Страница 33: ...31 EN 40 h 8 h 40 h 40 h 8 h 8 h 16 h 40 h Fig 5 1 Fig 5 2...

Страница 37: ......