6

Record the results of each formal inspection in the inspection and maintenance log in

the General Instruction (5902392) or use the i-Safe™ inspection web portal to maintain

your inspection records.

IMpoRTANT: If the full body harness has been subjected to fall arrest or impact

forces it must be immediately removed from service and destroyed.

IMpoRTANT:

Extreme working conditions (harsh environments, prolonged use, etc.)

may require increasing the frequency of inspections.

INSPECTION STEPS:

Step 1. Inspect harness hardware (buckles, D-rings, back pad, loop keepers);

these items must not be damaged, broken, distorted, and must be free of

sharp edges, burrs, cracks, worn parts, or corrosion. PVC coated hardware

must be free of cuts, rips, tears, holes, etc. in the coating to ensure non-

conductivity. Ensure that the release tabs of the buckle work freely and that

a click is heard when the buckle engages. Inspect parachute buckle spring.

Step 2.

Inspect webbing; material must be free of frayed, cut, or broken fibers.

Check for tears, abrasions, mold, burns, or discoloration. Inspect stitching;

check for pulled or cut stitches. Broken stitches may be an indication that

the harness has been impact loaded and must be removed from service.

When performing the annual formal inspection on the XP models of the

ExoFit harness, remove the back pad and leg strap pads to facilitate

inspection of the webbing.

Step 3. Inspect the labels: All labels should be present and fully legible.

Step 4. Inspect each system component or subsystem according to manufacturer’s

instructions.

Step 5. Record the inspection date and results in the inspection and maintenance

log in the General Instruction (5902392).

Step 6. Inspect the impact indicator on the Delta Harness models with stand-up

“D” and impact indicator. See Figure L. L-1 shows the harness in a normal

condition. The D-ring (10) is seated in the pivot (11). If the dorsal D-ring of

the harness has experienced an impact (12)(L-2), a red-colored area at the

base of the D-ring will become visible (13) indicating that an impact has

occurred. The impact indicator cannot be reset and the harness must be

removed from service and destroyed.

If inspection reveals a defective condition, remove the unit from service immediately

and destroy it.

NoTE: Only DBI-SALA or parties authorized in writing may make repairs to this

equipment.

MAINTENANCE, SERVICING, SToRAGE

A. WASHING INSTRUCTIONS FULL BODY HARNESS:

(See B. for Arc Flash Full Body Harness Washing Instructions)

Step 1. Spot clean the Delta full body harness with water and a mild soap solution.

The harness may be laundered by using a bleach-free detergent. Water

temperature for wash and rinse must not exceed 70° C (160° F).

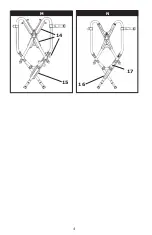

Step 2. To launder the full body harness, remove the pads. See Figure M. To

remove the pads, undo the snaps and zippers (14). The pads will fall away

from the harness straps. Only one leg pad is shown for clarity (15).

Step 3. Place the harness in the supplied laundry bag. The bag is designed to

prevent entanglement of harnesses and to protect the washing machine

from damage. Use of the laundry bag to wash the pads is optional.

Note: Use a bleach-free detergent when washing both the harness and the

pads.

Step 4. Harness and pads may be air dried or tumble dried on low heat (not greater

than 90° C (200° F).

Содержание DELTA 2

Страница 2: ...2 A B F D E 1 2 3 4 3 5 C 2 3 4 6 G H I J 2 J...

Страница 3: ...3 9 7 8 K L 1 L 2 11 10 13 L 12...

Страница 4: ...4 M N 14 17 16 15...

Страница 58: ...58...

Страница 59: ...59...