VLT

®

6000 HVAC

8

MG.60.G2.02 - VLT is a registered Danfoss Trademark

7.

Press “-” key until ‘6’ counts down to ‘0’ and

setting for

Ramp Up Time

reads ‘100 s.’

8.

Press OK key to enter new value into drive

controller.

9.

Press Display key to return to normal display.

Extended Menu

In some applications, the Quick Menu items will not

set up all the desired characteristics of the drive. To

access all VLT 6000 parameters, including the Quick

Menu parameters, press the Extend Menu key.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE:

Programming of parameter functions available

through Extended Menu is done in accor-

dance with same procedure as described for Quick

Menu functions.

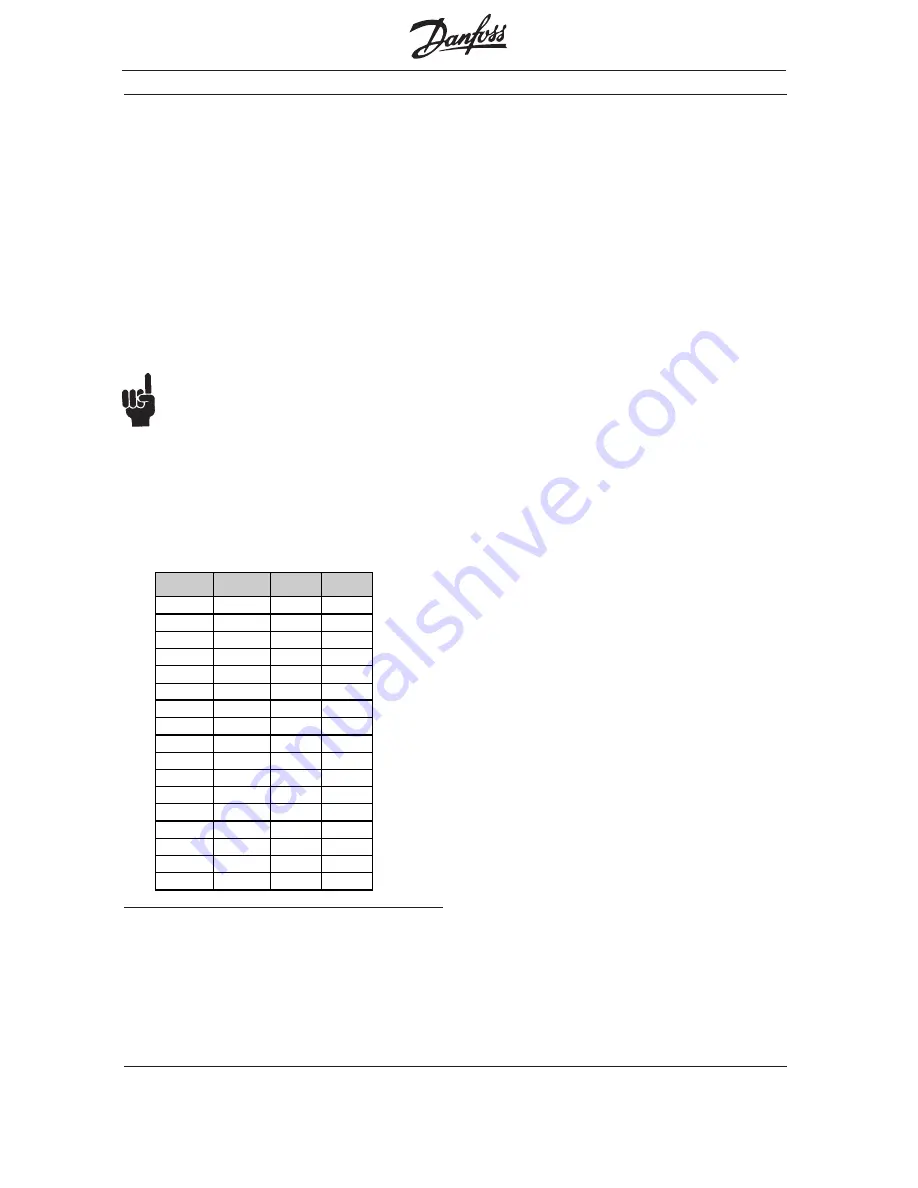

HP/kW Conversion

A conversion index for determining kW and HP

ratings is shown in Table 2.

Table 2 HP to kW Conversion Index

■

■

■

■

■

VLT 6000 Functional Features

kW

HP

kW

HP

0.25 0.33 45 60

0.37 0.5 55 75

0.55 0.75 75 100

0.75 1.0 90 125

1.1 1.5 110

150

1.5 2.0 132

175

2.2 3.0 160

200

3.0 --- 200

300

4.0 5.0 250

---

5.5 7.5 300

---

7.5 10 315

350

11 15 355

450

15 20 400

500

18.5 25 450 600

22 30

30 40

37 50

The FLN protocol built into the VLT 6000 frequency

converter allows programming of numerous features

and monitoring of the drive via the serial bus and the

standard RS-485 port. The VLT 6000 also has the

capability to control closed or open loop systems on

its own and has been designed specifically for HVAC

applications. Always accessible in real-time are the

system status, what the motor and drive are doing,

and if there are any problems. The VLT 6000

continuously monitors all aspects of motor and drive

status and issues alarms or warnings for adverse

conditions.

The FLN interacts with the drive based upon a point

map database and the selected interface strategy.

Many, but not all, drive features are accessible

through the point map. See the

VLT 6000 Operating

Instructions

for more drive details. Table 8 lists the

map points and Table 9 supplies definitions. Below is

a review of some frequently used drive features and

the associated point map numbers.

Drive Operation (03-14)

These points provide the FLN with operational status

information such as output frequency, motor current,

output voltage, power and energy. The run time in

hours that power has been supplied to the motor is

also stored for display, along with cumulative energy

used in kWh.

Motor and Drive Thermal Protection (15, 16, 18)

The motor and drive are protected against thermal

overload. The percentage of thermal load is dis-

played. Point 18 indicates if either the motor or drive

thermal limit has been exceeded.

Set-up 1 - 4 (17) (29)

The drive is capable of maintaining four independent

program set-ups. Each set-up supports independent

point map configurations. Seasonal changes, various

acceleration or deceleration rates, or other operation

modes can be accommodated. Point 17 indicates

which setup is active. The set-up change is

programmed through the drive’s keypad or digital I/

Os. Day/night operation is implemented in the point

map (29) but is not used in this application.