3.3 Commissioning Guide

This guideline is only describing basic configuration and

optimizing of MCO 305, before starting the following steps

must be completed.

1.

Basic commissioning of VLT AutomationDrive.

NOTE

VLT AutomationDrive must be optimized and have good

control over the motor and application before commis-

sioning MCO 305. Guidelines can be found in

VLT

AutomationDrive Operating Instructions (MG.33.AX.XX)

.

2.

Install the PC software tools (MCT 10 Set-up

Software)

3.

Establish communication between PC and VLT

AutomationDrive using USB, RS-485 or PROFIBUS

DPV1.

Then follow these steps to set-up and optimize MCO 305.

1.

Setting of basic MCO 305 parameters (groups 32-

** and 33-**).

2.

Connect and test encoder(s).

3.

Optimize PID controller.

NOTE

Error 113 will show up right after power up if the VLT

AutomationDrive is not ready. The VLT AutomationDrive is

in the “Not ready” state when

-

it has an alarm (trip),

-

it is in hand mode, [Hand on] key,

-

local LCP stop is activated, [OFF] key,

-

there is no signal on input 37 safe stop (only FC

302).

Error 113 can only be reset using the ERRCLR command or

with BREAK [Esc] in the PC software and only when the

VLT AutomationDrive is in the “ready” state, which means

none of the above may be true. The VLT AutomationDrive

monitoring function can be switched off by selecting [0] in

33-82 Drive Status Monitoring

.

Read the Safety Instructions before installing the frequency

converter.

3.4 Basic MCO Parameter Settings

The following parameters must always be checked and if

necessary adjusted. Depending on the requirements of the

application it might be necessary to adjust other

parameters as well.

For the other parameters, use the default settings at first

and then optimize the controller as needed at a later point

in time with a

Testrun

.

The MCT 10 Set-up Software will support you to set the

parameters in LCP. For a detailed description of all

parameters, please refer to

8 Appendix

.

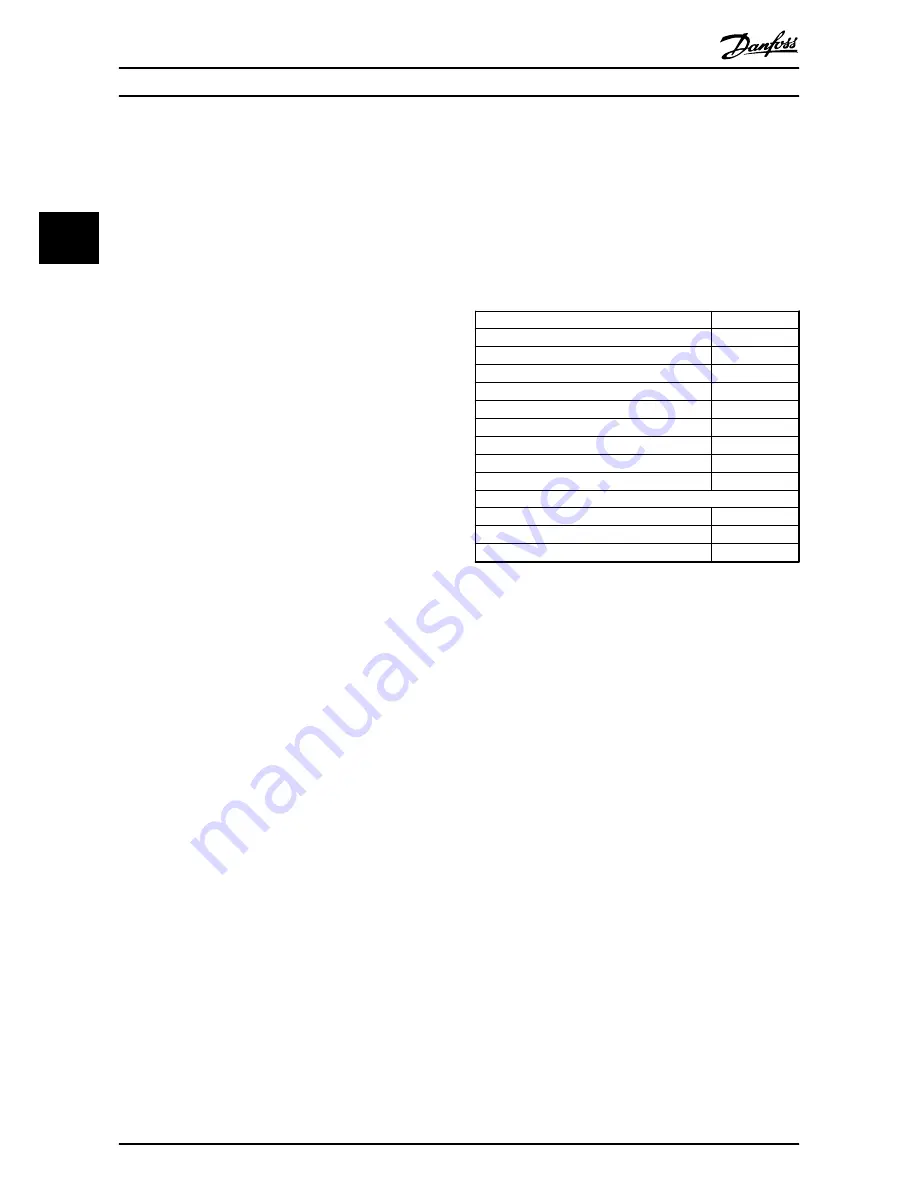

3.4.1 Setting of Encoder Parameters

Define the used type of feedback encoder in parameter

group 32-0*.

These defaults are set:

32-0* Encoder 2 - Feedback

Default

32-00 Incremental Signal Type

[1] RS422

32-01 Incremental Resolution

1024

32-02 Absolute Protocol

[0] None

32-03 Absolute Resolution

8192

32-05 Absolute Encoder Data Length

25

32-06 Absolute Encoder Clock Frequency

262000

32-07 Absolute Encoder Clock Generation

[1] On

32-08 Absolute Encoder Cable Length

0

32-09 Encoder Monitoring

[0] Off

For CAN Encoders

32-14 Enc.2 node ID

127

32-15 Enc.2 CAN guard

[0] Off

33-91 X62 MCO CAN baud rate

[20] 125 kbps

3.4.2 Setting of parameters for CANopen

feedback encoder

-

In

32-00 Incremental Signal Type

select the setting

[3] “CAN encoder”.

-

In

32-01 Incremental Resolution

set the resolution

of the encoder.

-

In

32-14 Enc.2 node ID

set the CAN ID of the

encoder.

-

In

32-15 Enc.2 CAN guard

activate or deactivate

the guarding.

-

In

33-91 X62 MCO CAN baud rate

set in the CAN

bus baud rate.

The following parameters are only relevant for synchro-

nizing applications when a master encoder signal is used.

These defaults are set:

How to Install

MCO 305 Operating Instructions

14

MG.33.K3.02 - VLT

®

is a registered Danfoss trademark

3

3