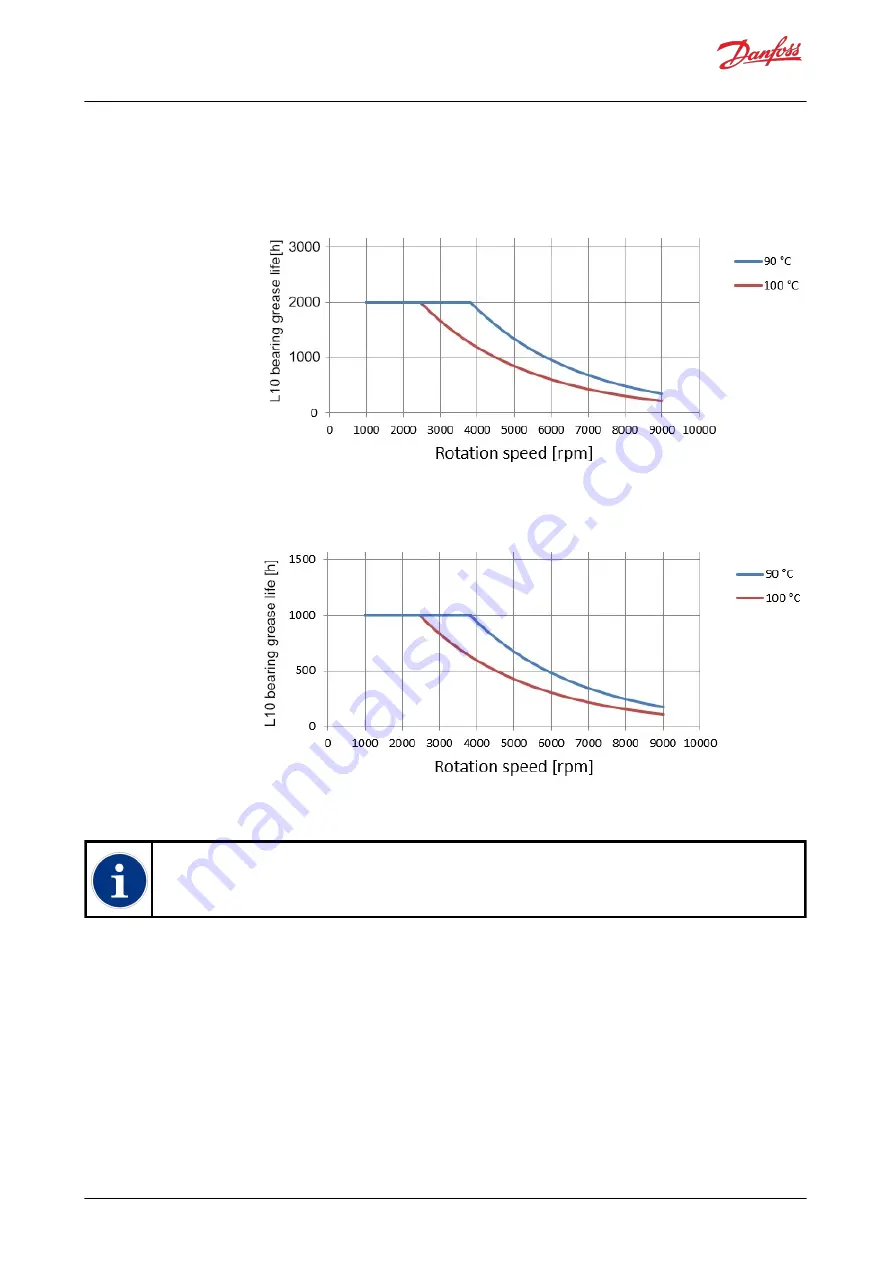

Figure 21. Relubrication interval of the machine (BHS option) compared to rotation speed and bearing

temperature

Figure 22. Relubrication interval of the machine (BHS option) compared to rotation speed and bearing

temperature, vertical installation

For more information about the location of grease nipples and grease escape holes, see Chapter Connections and

interfaces.

Bearing relubrication:

1. Make sure that the machine has reached its operating temperature.

2. Remove the plugs from the grease escape holes.

3. Open the grease nipple plugs.

4. Use grease piston to enter speci c amount of grease into the grease nipple.

5. If possible, let the machine run approximately one hour to let the old grease exit. NOTE! It is

normal if no grease exits the electric machine. This is because the cavities inside the electric

machine can hold a lot of grease.

6. Install the plugs on the grease nipples and on the grease escape holes.

EM-PMI240

8. Maintenance

44 |

©

Danfoss | Produced By: Danfoss Power Solutions | September 2020

| BC355256345493en-000103

Содержание EM-PMI240

Страница 1: ...User Guide Motor Generator EM PMI240 danfoss com...

Страница 59: ......