Installation manual

11

EKHBRD011~Y1

Indoor unit for air to water heat pump system

4PW54465-1C

■

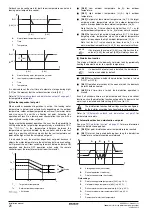

When loosening a flare nut, always use two wrenches together.

When connecting the piping, always use a spanner and torque

wrench together to tighten the flare nut to prevent flare nut

cracking and leaks.

Not recommended, but in case of emergency

Should you be forced to connect the piping without a torque

wrench, follow the following installation method:

■

Tighten the flare nut using a spanner until the tightening

torque suddenly increases.

■

From that position further tighten the flare nut the angle listed

below:

Water piping work

Checking the water circuit

The units are equipped with a water inlet and water outlet for

connection to a water circuit. This circuit must be provided by a

licensed technician and must comply with all relevant European and

national regulations.

Before continuing the installation of the unit, check the following

points:

■

The maximum water pressure is 4 bar.

■

The maximum water temperature is 85°C.

■

Drain taps must be provided at all low points of the system to

permit complete drainage of the circuit during maintenance.

One drain valve in the indoor unit, and a drain valve on the

expansion vessel are provided to drain the water from the indoor

unit water system.

■

Make sure to provide a proper drain for the pressure relief valve

to avoid any water coming into contact with electrical parts.

■

Air vents must be provided at all high points of the system. The

vents should be located at points which are easily accessible for

servicing. An automatic air purge is provided inside the indoor

unit. Check that this air purge valve is not tightened too much so

that automatic release of air in the water circuit remains possible.

■

Take care that the components installed in the field piping can

withstand the water pressure and temperature.

■

Always use materials which are compatible with the water used

in the system and with the materials used on the indoor unit.

Checking the water volume and expansion vessel

pre-pressure

The unit is equipped with an expansion vessel of 12 litre which has a

default pre-pressure of 1 bar.

To assure proper operation of the unit, the pre-pressure of the

expansion vessel might need to be adjusted and the minimum and

maximum water volume must be checked.

1

Check that the total water volume in the installation, excluding

the internal water volume of the unit, is 20 l minimum.

2

Using the table below, determine if the expansion vessel pre-

pressure requires adjustment.

Piping size

(mm)

Further tightening

angle (degrees)

Recommended arm

length of spanner (mm)

Ø9.5

60~90

±200

Ø15.9

30~60

±300

The unit is only to be used in a closed water system.

Application in an open water circuit can lead to excessive

corrosion of the water piping.

1

Piping union

2

Spanner

3

Flare nut

4

Torque wrench

4

2

3

1

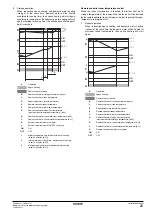

In most applications this minimum water volume will have a

satisfying result.

In critical processes or in rooms with a high heat load

though, extra water volume might be required.

When circulation in each space heating/radiator loop is

controlled by remotely controlled valves, it is important that

this minimum water volume is kept even if all the valves are

closed.

Example

1

Outdoor unit

10

Radiator (field supply)

2

Indoor unit

11

Electronic expansion

valve

3

Refrigerant heat

exchanger

C1

Remote controller

4

Water heat exchanger

M1...M3

Individual motorized valve

to control loop radiators

(field supply)

5

Compressor

6

Pump

T1...T3

Individual room

thermostat (field supply)

7

Shut-off valve

8

Collector (field supply)

A

Installation space

9

By-pass valve

(field supply)

B

Living room

7 7 8

4

3

2

9

1

6

10

5

T3

T2

A

B

C1

M3

M2

M1

T1

11

11

Содержание EKHBRD-AY1

Страница 43: ...V1 Y1 NOTES 5 5...

Страница 44: ...4PW54465 1C Copyright Daikin...