35

Optional

Functions

Optional P

a

rt

s

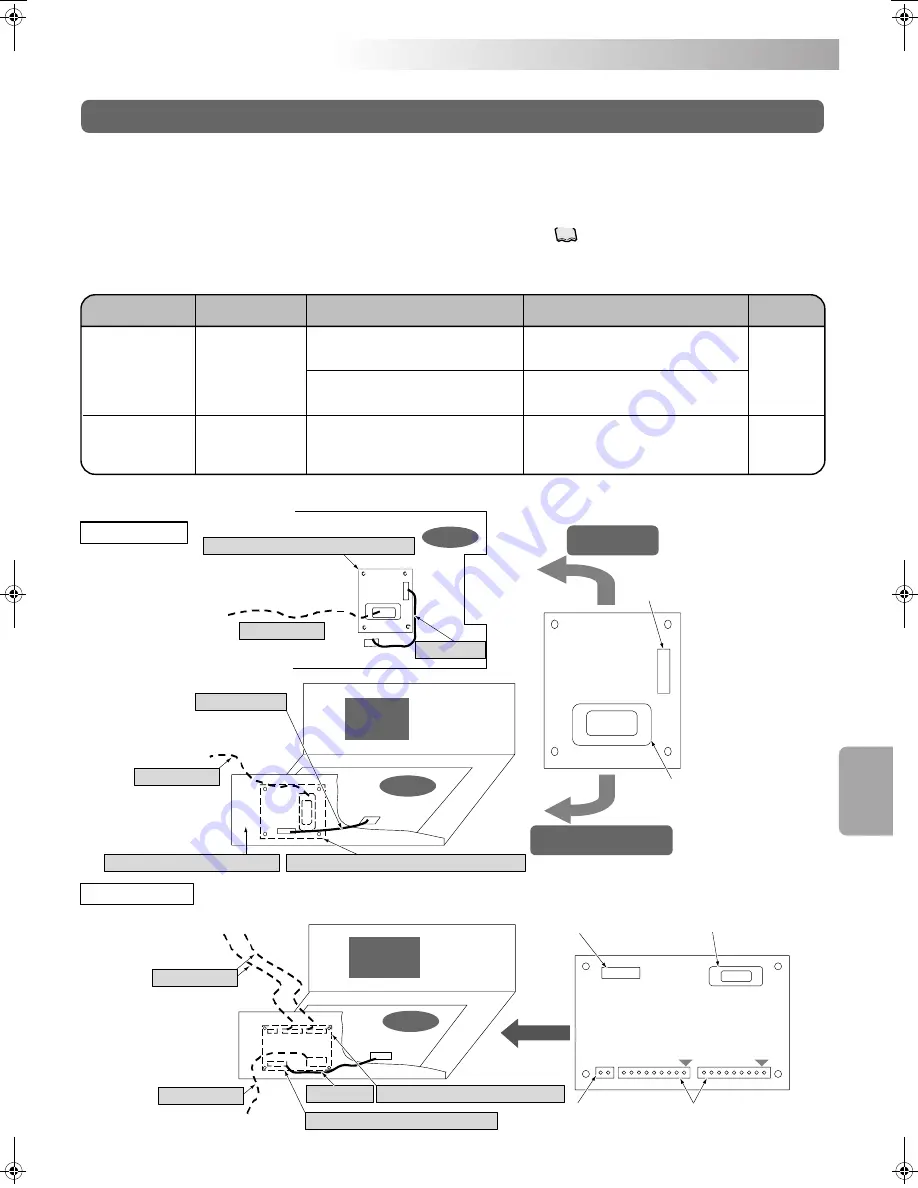

To main machine or PC

(Serial communication only)

To main machine or PC

(Serial communication only)

Control board

Control board

Control board

CN1

CN2

CN12

AKZ148/328/438,

AKZJ188/358/458

Connection to [CN12] on Oil Cooling Unit

control board via supplied lead wire.

CN1

CN2

AKZ8–OP–CS

Connection to RS232C port of main machine

or PC. (D-SUB, 9-pin female connector)

AKZ8-OP-CS

Inverter

board

CN1

CN2

CN12

AKZ8-OP-CS

AKZ568/908, AKZJ568/908

Connection to [CN14] on Oil

Cooling Unit control board via

supplied lead wire

Connection to RS232C port of

main machine or PC

(D-SUB, 9-pin female connector)

CN1

CN2

AKZ8–OP–CSP

Pin No. 1

Pin No. 1

DOUT(CN4)

DIN(CN3)

CN5

Not used

(No connection)

Connection to main machine

PLC output port

RS232C

CN14

To main machine or PC

(Serial communication)

To main machine

(Parallel communication)

CN1

CN2

CN3

CN4

CN5

Locking support (×4), Mounted to control board

Supplied lead wire

Prepared by user

Prepared by user

Supplied lead wire

Supplied lead wire

Electrical equipment box front sheet metal

Electrical equipment box front sheet metal

Locking support (×4), Mounted to sheet metal inner surface

Locking support (×4), Mounted to sheet metal inner surface

Inverter

board

Prepared by user

Prepared by user

Optional Parts

Communication with main machine

When this optional board is mounted to the Oil Cooling Unit to connect this unit to the main machine:

1. You can change the operation mode and operation setting from the main machine.

2.

You can read

the Oil Cooling Unit alarm code and temperature data (machine temperature, room temperature, inlet

oil temperature, outlet oil temperature, temperature difference between inlet and outlet, and inverter frequency

data)

from the main machine.

∗

To execute parallel communication, you must set the corresponding parameter. (See page .) The Oil Cooling Unit cannot communicate

with the main machine simply by mounting this optional board. For serial communication, parameter setting is not required.

Optional parts

Type

Communication

method

Mounting position

Compatible model

Specification No.

AKZ8–OP–CSP

AKZ8–OP–CS

Serial

communication

only

Serial or parallel

communication

AKZ148, AKZ328, AKZ438, AKZJ188,

AKZJ358, AKZJ458

AKZ568, AKZ908, AKZJ568, AKZJ908

AKZ568, AKZ908, AKZJ568, AKZJ908

Back of Oil Cooling Unit electrical

equipment box front sheet metal

Back of Oil Cooling Unit electrical

equipment box front sheet metal

Upper surface of Oil Cooling Unit

control board

SS08303

SS08370

Mounting procedure

AKZ8–OP–CS

AKZ8–OP–CSP

25

PIM00132A_EN.fm 35 ページ 2007年9月20日 木曜日 午後3時4分