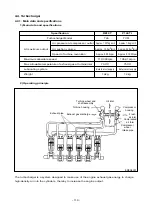

(2) Rotor radial play

(3) If the measured axial and radial plays are beyond the limit of wear, replace or repair the

turbocharger.

3) Guide for disassembling/cleaning and checking the turbocharger

First, disassemble the turbocharger from the engine and clean/check it with the oil inlet and

outlet plugged with tape and so on.

4) Precautions for reassembling the tarbocharger onto the engine

For reassembly of the turbocharger or handling it after reassembly operation, be sure to

observe the following precautions:

Especially, exercise extreme care to prevent foreign matters from entering the inside of the

turbocharger.

(1) Lubricating system

•

Before reassembling the turbocharger onto the engine, inject new oil in the oil inlet port

and lubricate the journal and thrust bearings by rotating them with hand .

•

Clean not only the pipes installed between the engine and oil inlet port but also the oil

outlet pipe and check them for damage or foreign matters.

•

Assemble each joint on oil pipes securely to prevent oil leaks.

(2) Intake system

•

Check the inside of the intake system for foreign matters.

•

Assemble each joint on the intake duct and air cleaner securely to prevent air leaks.

- 125 -

EA8M4004

Dial gauge

Magnetic vise

Oil inlet

Oil outlet

Move the turbine shaft

in both directions

simultaneously

Radial play

Limit of wear : 0.075~0.11mm

Limit of wear : 0.12mm