24

6. MAINTENANCE & REPAIR

WARNING!

Please see Chapter 1 regarding Safety

•

Turn the input power OFF before working on any DABOTEK stud welder.

•

Do not touch electrically live parts or electrode with your skin or wet clothing

•

Insulate yourself from work and ground

•

Always wear dry insulating gloves

•

Have an electrician install the DABOTEK stud welder.

•

An authorized DABOTEK Service Center must do all maintenance and repairs that require

opening the case.

If

The Studhorse

does not operate properly, stop work immediately and investigate the cause of

the malfunction.

Please note: Opening up the case voids the Warranty

.

Maintenance and repair should only be performed by an authorized DABOTEK Service Center,

or by the factory. Do not permit untrained persons to inspect, clean, or repair

The Studhorse.

Please call the factory for the location of the Authorized DABOTEK Service Center nearest you.

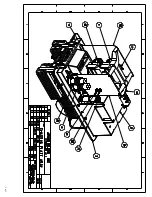

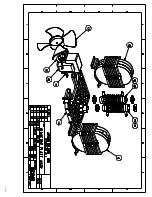

Since there are no moving parts other than the fan in the power source, basic preventive

maintenance only involves keeping the welder clean and free from metallic dust. Periodically,

you should ask your Authorized Service Center to remove the cover from the case, remove

accumulated dust and dirt from the air passages and the interior components, using clean low-

pressure air. It is imperative that the air passages to the interior of the unit be free of dirt to

ensure adequate circulation of cooling air, especially over the rectifier bridge plates. The

frequency of cleaning will depend on the location of the unit, the amount of dust in the

atmosphere and number of operating hours.

Operators are encouraged to check the following to maintain The Studhorse power supply:

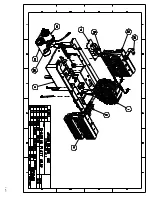

1. Visually inspect the case, panels, handles and cables for damage, which may occur in transit

and in normal use.

2. Check the machine for any loose or damaged parts.

3. Check air passages of power source for any debris that may obstruct airflow through the

welder.

4. Monitor and schedule having the machine cleaned with compressed air by an authorized

service center.

Содержание DT1200i

Страница 20: ...20 5 1 Visually Inspecting Welded Studs continued...

Страница 21: ...21 5 1 Visually Inspecting Welded Studs continued...

Страница 22: ...22 5 1 Visually Inspecting Welded Studs continued...

Страница 23: ...23 5 1 Visually Inspecting Welded Studs continued...

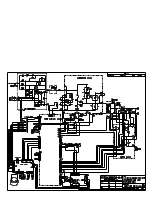

Страница 29: ......

Страница 30: ......

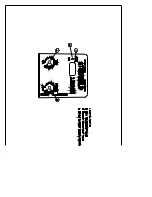

Страница 31: ...1 of 1...

Страница 32: ...1 of 1...

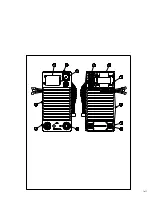

Страница 33: ...1 of 1...

Страница 34: ...1 of 1...