14

4. OPERATION

WARNING!

PLEASE READ CHAPTER 1 REGARDING SAFETY

4.1 General Description

The 1200 Amp Studhorse power source combines time-proven technology with modern

technology to provide high-quality performance. The digitally controlled SCR type inverter is

very reliable in welding applications and capable of welding 5/8-inch full-base weld studs in a

variety of applications. Duty Cycle at 1200 Amps is 6 per minute using 5/8-inch studs. 30 Amp

Slo-Blow fuses provide protection for all input voltages.

4.2 Design Features

The Studhorse

power source is designed to be portable and easily transported to provide many

benefits. No crane or special lifting devices are required to move or maintain the machine. The

machine provides Constant Power output with Inverter-smooth arc, incorporating digitally

controlled start/stop with no mechanical contactor. Other features include regulated output,

step-less weld power and time adjustment, short-circuit protection, automatic line voltage

protection and 5-zones of thermal protection.

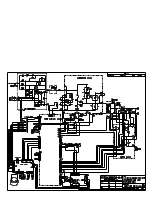

4.3 Operational Controls and Settings

– also refer to Figure 4.1

4.3.1 Circuit Breaker (Power On/Off)

The Circuit Breaker serves as the main input power switch and located on the control panel

at the rear of the machine. Move the switch lever up to the ON position to start the machine.

The Power-On indicator light will show that input power is being supplied to the machine.

4.3.2 Digital Meter on The DT1200i model

The digital current and timer meter displays current when the push button toggle switch is

pushed once, and displays time when pushed in again.

After switching on the input power to the machine, the four-digit display shows the

operational mode PA. The display shows the actual Current for three seconds after each

Stud has been welded. The Current setting is displayed as ”(X)XXX” and actual Current is

displayed as ”(X)XXX”.

If display flashes, the machine has exceeded its temperature limits. Wait a few minutes until

the display has stopped flashing, and you can resume welding.

Содержание DT1200i

Страница 20: ...20 5 1 Visually Inspecting Welded Studs continued...

Страница 21: ...21 5 1 Visually Inspecting Welded Studs continued...

Страница 22: ...22 5 1 Visually Inspecting Welded Studs continued...

Страница 23: ...23 5 1 Visually Inspecting Welded Studs continued...

Страница 29: ......

Страница 30: ......

Страница 31: ...1 of 1...

Страница 32: ...1 of 1...

Страница 33: ...1 of 1...

Страница 34: ...1 of 1...