Operating instructions Multi-cell compressor RKL 160

Maintenance

23

7 Maintenance

7.1 Safety during maintenance work

See chapter 2.6 "Occupational safety and special risks".

Personal protective equipment

The following must be worn during all maintenance work:

Safety working clothing

Protective gloves

Safety shoes

Safety goggles

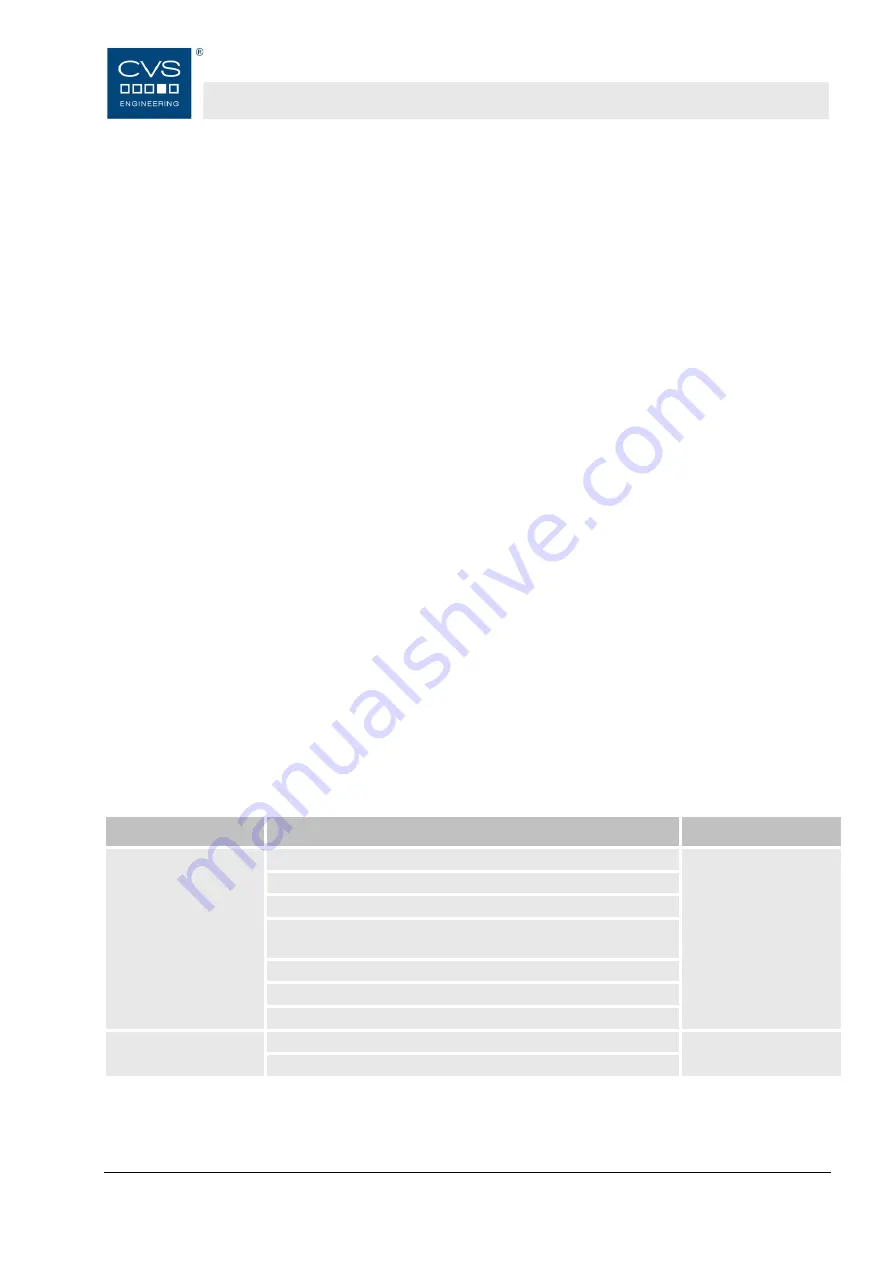

7.2 Maintenance schedule

The following describes the maintenance work that is necessary for

an optimum, trouble-free operation. Maintenance intervals must be

observed.

If increased wear of individual components or functional groups is

determined during regular inspections, the operator has to reduce

the required maintenance intervals on the basis of the actual signs

of wear.

Changes compared to normal operation (increased power

consumption, temperatures, vibrations, noises, etc. or response of

monitoring systems) lead to the assumption that the functions are

impaired. These then have to be subjected to an inspection by

specialised staff.

In case of queries regarding the maintenance work and intervals:

contact the manufacturer (service address

page 2).

For maintenance schedule refer to next page.

Maintenance schedule

Interval

Maintenance work

To be carried out by

Weekly

Check the retaining screws

1)

(see Chapter 6.4).

Operator

Clean RKL 160 (see chap. 7.3).

Check and clean cooling air guidance (refer to chapter 7.3).

Check air filter's degree of soiling

(refer to chapter 7.3)

Check air filter hose for leaks.

Check connection to drive (articulated shaft, coupling)

1)

.

Check screw connections.

quarterly

Check height wear of pipe slider (refer to chapter 6.4).

Specialised staff

Check non-return valve (refer to chapter 6.4).

1) Observe manufacturer's recommendations

Tab. 4: Maintenance schedule

Содержание RKL 160

Страница 29: ...Operating instructions Multi cell compressor RKL 160 Index 29...

Страница 30: ......

Страница 31: ......

Страница 32: ......