8

‐

2

MAINTENANCE

SCHEDULE

We

suggest

you

do

the

maintenance

on

schedule.

The

recommended

schedule

includes

three

periods,

1.Daily

maintenance.

2.Monthly

maintenance.

3.

Six

months

maintenance.

Before

beginning

a

day’s

work

1.

Please

check

the

hydraulic

oil

level.

If

oil

level

volume

is

below

1/2,

please

add

oil

as

necessary.(Filling

up

to

2/3

level

is

better

for

system

operation.)

2.

Please

check

the

cutting

fluid

level,

adding

fluid

as

necessary.

If

the

fluid

appears

contaminated

or

deteriorated,

drain

and

replace

it.

3.

Please

check

the

saw

blade

to

ensure

that

it

is

properly

positioned

on

both

the

drive

and

idle

wheels.

4.

Please

make

sure

that

the

saw

blade

is

properly

clamped

by

the

left

and

right

inserts.

5.

Please

check

the

wire

brush

for

proper

contact

with

the

saw

blade.

Replace

the

wire

brush

if

it

is

worn

out.

After

ending

a

day’s

work

Please

remove

saw

chips

and

clean

the

machine

with

discharging

the

cutting

fluid

when

work

has

been

completed.

Do

not

discharge

cutting

fluid

while

the

saw

blade

is

operating

because

it

will

cause

severe

injury

on

operator’s

hand.

Be

sure

the

saw

blade

is

fully

stop,

it

will

be

performed

after

working

inspection.

Every

month

Please

apply

grease

to

the

following

points:

1.

Idle

wheel

2.

Drive

wheel

3.

Blade

tension

device

Recommended

Grease:

Shell

Alvania

EP

Grease

2

Mobil

Mobilplex

48

Every

three

months

Replace

the

transmission

oil

after

operating

for

three

months

(or

600

hours).

Recommended

Grease:

Shell

Alvania

EP

Grease

2

Mobil

Mobilplex

48

(600W

Cylinder

oil)

Содержание SH-3026L

Страница 2: ......

Страница 8: ......

Страница 13: ...1 5 Illustration Emergency Stop Emergency Stop Button ...

Страница 15: ...1 7 Illustration Safety Labels ...

Страница 20: ...2 4 FLOOR PLAN Machine top view Machine front view ...

Страница 21: ...2 5 Machine front view ...

Страница 22: ......

Страница 32: ......

Страница 48: ......

Страница 50: ...5 2 ...

Страница 51: ...5 3 ...

Страница 52: ...5 4 ...

Страница 53: ...5 5 ...

Страница 54: ......

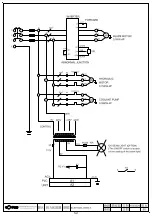

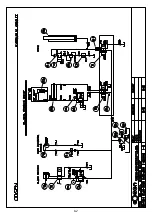

Страница 55: ...6 1 Section 6 HYDRAULIC SYSTEM HYDRAULIC CIRCUIT DIAGRAM ...

Страница 56: ...6 2 ...

Страница 62: ......

Страница 79: ...6 5 4 1 2 3 7 8 9 SH 3026L 2015 12 4 COLUMN ASSEMBLY S3026 11000 立柱組 SERIES PART LIST 10 7 ...

Страница 81: ...1 4 3 2 HEIGHT CONTROL ASSEMBLY SH 3026L 2015 12 8 S3026 11400 高度控制組 SERIES PART LIST 10 9 ...

Страница 83: ...SH 3026L 2015 12 8 CONTROL BOX ASSEMBLY S3026 13000 控制箱組 SERIES PART LIST 5 1 3 4 2 10 11 ...

Страница 85: ...3 2 5 4 1 VISE ASSEMBLY SH 3026L 2015 12 8 S3026 22000 虎鉗組 SERIES PART LIST 10 13 ...

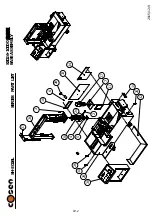

Страница 88: ...SH 3026L 2015 12 10 S3026 30000 鋸弓組 SAW BOW ASSEMBLY SERIES PART LIST 5 13 3 4 8 10 16 ...

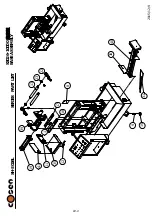

Страница 97: ...2015 12 4 SAW ARM ASSEMBLY SH 3026L C260L 31000 鋸臂組 SERIES PART LIST 6 7 9 5 11 10 2 4 8 3 1 10 25 ...

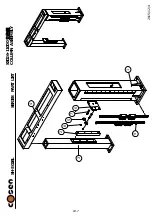

Страница 99: ...2015 12 4 WIRE BRUSH ASSEMBLY SH 3026L C260L 32200 鋼刷組 SERIES PART LIST 4 3 6 5 7 7 9 1 8 2 8 10 27 ...

Страница 101: ...IDLE WHEEL ASSEMBLY SH 1000F 2015 12 4 C300H 30300A 上輪組 SERIES PART LIST 1 6 2 5 3 7 8 6 4 10 29 ...

Страница 104: ......

Страница 105: ......