4

C6.2.15/0815/E

ARI Conditions:

Evaporating temperature ...... 7.2°C

Liquid sub-cooling ......................... 8.3K

Condensing temperature .....54.4°C

Ambient temperature ..................... 35°C

Suction gas superheats ........... 11K

EN 12900 Conditions:

Evaporating temperature .......... 5°C

Liquid sub-cooling ............................ 0K

Condensing temperature ........ 50°C

Ambient temperature ..................... 35°C

Suction gas superheats ........... 10K

2.3 Application range

2.3.1 Qualified refrigerants and oils

IMPORTANT

It is essential that the glide of refrigerant blends (primarily R407C) is

carefully considered when adjusting pressure and superheat controls.

Oil recharge values can be taken from Copeland Scroll compressors brochures or Copeland

™

brand products Select software at

www.emersonclimate.eu

.

Qualified refrigerants

R407C

R410A

Copeland brand

products standard oil

Emkarate RL 32 3MAF

Servicing oil

Emkarate RL 32 3MAF

Mobil EAL Arctic 22 CC

Mobil EAL Arctic 22 CC

Table 1: Qualified refrigerants and oils

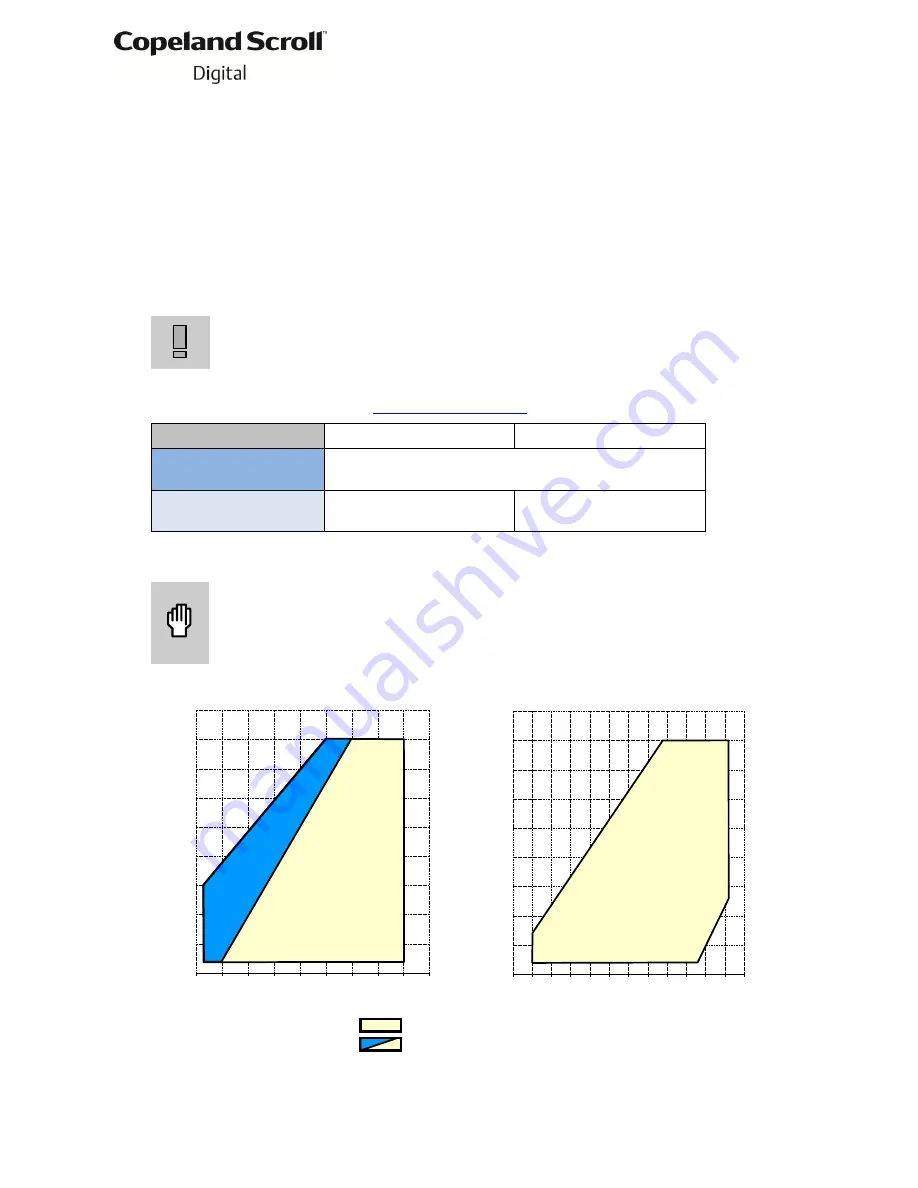

2.3.2 Application limits

CAUTION

Inadequate lubrication! Compressor breakdown!

The superheat at the

compressor suction inlet must always be sufficient to ensure that no

refrigerant droplets enter the compressor. For a typical evaporator-expansion

valve configuration a minimum stable superheat of at least 5K is required.

ZRD42K*E to ZRD81K*E ZRD94K*E & ZRD125K*E

Figure 1: Application envelopes with R407C (Dew point)

25

30

35

40

45

50

55

60

65

70

-25

-20

-15

-10

-5

0

5

10

15

20

Con

dens

ing T

e

mpe

ra

tu

re

(

o

C)

Evaporating Temperature (

o

C)

R407C

25

30

35

40

45

50

55

60

65

70

-35 -30 -25 -20 -15 -10 -5

0

5

10

15

20

25

Con

dens

ing T

e

mpe

ra

tu

re

(

o

C)

Evaporating Temperature (

o

C)

R407C

10K Suction superheat

25

0

C Suction gas return