18

C6.2.15/0815/E

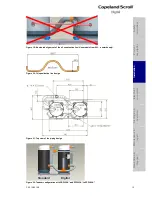

3.13 Suction line noise and vibration

Copeland Scroll compressors inherently have low sound and vibration characteristics. However

in some respects the sound and vibration characteristics differ from reciprocating compressors

and in rare instances could result in unexpected sound generation. One difference is that the

vibration characteristic of the scroll compressor, although low, includes two very close

frequencies, one of which is normally isolated from the shell by the suspension of an internally-

suspended compressor. These frequencies, which are present in all compressors, may result in

a low-level "beat" frequency that can be detected as noise coming along the suction line into the

building under some conditions. Elimination of the beat can be achieved by attenuating either of

the contributing frequencies. This is easily done by using one of the common combinations of

recommended design configurations. The scroll compressor makes both a rocking and twisting

motion and enough flexibility must be provided in the line to prevent vibration transmission into

any lines attached to the unit. In a split system, the most important goal is to ensure minimal

vibration in all directions at the service valve to avoid transmitting vibrations to the structure to

which the lines are fastened.

A second difference of the Copeland Scroll is that under some conditions the normal rotational

starting motion of the compressor can transmit an "impact" noise along the suction line. This

may be particularly pronounced in three-phase models due to their inherently higher starting

torque. This phenomenon, like the one described previously, also results from the lack of internal

suspension and can be easily avoided by using standard suction line isolation techniques as

described below. The sound phenomena described above are not usually associated with

reversible heat pump systems because of the isolation and attenuation provided by the reversing

valve and tubing bends.

Recommended configuration

Tubing configuration: ........small shock loop

Service valve: ..................."angled valve" fastened to unit / wall

Suction muffler: .................not required

Alternative configuration

Tubing configuration: ........small shock loop

Service valve: ..................."straight through" valve fastened to unit / wall

Suction muffler: .................may be required (acts as dampening mass)