user instructions TWIN80C_EN

3

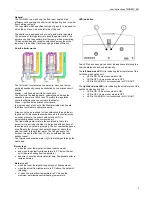

Display

To be able to read the codes of the, open the cover in front of

the appliance.

A = Status

B = Reading

C = “+ button”

D = “- button”

E = Set / Reset

F = Flame

The left 7-segment LED shows the status or the menu step.

The two right 7-segment LED's show the temperature, the

pressure or the parameter value.

What is a functional blocking?

During blocking operation, the display status shows a

continuous

indication. The regulation blocks the burner till

blocking conditions are within certain requirements.

Most blocking actions restore automatically in time. Some

blocking operations need a reset of the 230V supply power or an

action manually.

Note that each blocking operation will stay at least with 3

minutes anti-cycling time.

What is a functional lock-out?

During lock-out operation, the display status shows a

flashing

indication.

Pump runs over the heating circuit (max 24 hr).

Fan post rinses for 1 minute at 2700 rpm (some lock-outs)

Most lock-out operations can be restored by pressing the

‘Set/Reset’ button. It is advised to use this button not more than

3 times in a row. Ask your installer for help.

Note that some lock-out operations need a reset of the 230V

supply power.

Status indication during normal operation

Display

Description

-

Initialisation after restoration of supply power

U

Reversed neutral and line

O

No heat demand, stand-by

C

Central heating heat demand, burner off

C.

Central heating heat demand, burner on

P/C.

(Central heating) heat demand, low load water

pressure

A/C.

(Central heating) heat demand, low load chimney

temperature

c

Central heating pump post-running

b

HWS burner off/ pump post running

b.

HWS burner on

P/b.

HWS, low load by water pressure

A/b.

HWS, low load by chimney temperature

O

Frost protection burner off pump running 8C

o.

Frost protection burner on 3C

C

FLASHING

Chimney sweeper function (temp display

max/min/ionisation)

Status indication during “blocking” mode

(intermittent “L” for master and “r” for slave)

Display

Description

1

Flow sensor open circuit

1.

Flow sensor short circuit

2

Return sensor open circuit

2.

Return sensor short circuited

4

Flue gas sensor open circuit

A

Flue gas temperature > 80°C

H

Flow sensor > 105°C while the burner was off

J

Blocking flow temperature

(3 minutes anti-cycling time)

P

Pump test / Start function blocking / Water

pressure

nc

Electronics interruption

(manual reset by interruption of electrical supply)

E

No slave connected

b/r

HWS right unit

9

Flow / Return temperature to high

Status indication of ”lock-out” mode (flashing)

(intermittent “L” for master and “r” for slave)

Display

Description

1

Boiler does not pass start temperature test

2

Too many restarts

3

Internal regulation fault / A/D conversion fault /

external sensor fault /Too many restarts

4

5

Fan error

6

7

Gas valve error

8

Flame detected with closed gas valve

A

Flue gas temperature > 95°C

E

Internal interlock fault

H

Flow sensor > 105°C with burner on

F

Too many ignition attempts during

O

Gas valve connection error