Tech Support: 1‐818‐841‐5500

3

Congratulations, the Comco AccuFlo® model AF10‐CE you have purchased incorporates the latest

development in micro‐abrasive blasting – Simoom Technology.

This patented method of mixing air and abrasive delivers a steady and consistent stream of

abrasive allowing you to process parts efficiently and with uniform results. Here’s why it works so

much better than other micro‐abrasive blasters.

Activate the blast and the modulator opens and closes 50 or 60 times per second (depending on

local power supplied at 50Hz or 60Hz), producing pulses in the air stream. The rapid change in air

pressure fluidizes the abrasive above the orifice. The powder is then drawn through the orifice

into the mixing chamber where it enters the air stream and exits the AccuFlo® through the

PowderGate® valve traveling out to the nozzle.

The strength of these modulated pulse and the diameter of the orifice determines the amount of

abrasive that drops into the mixing chamber. Three mechanisms enable you to change the amount

of abrasive in the air stream: the tank orifice, abrasive blend and bypass tube.

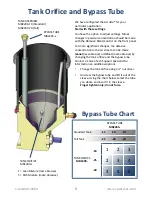

Tank Orifice:

A larger orifice increases abrasive flow. In most cases the orifice should be at least 5

times the size of the average particle size, but not larger than the nozzle.

Bypass Tube:

The bypass tube creates an alternate path for the modulator pulses, bypassing the

orifice. A larger bypass tube dampens the impact of each pulse, reducing media flow.

Abrasive Blend:

The abrasive blend changes the strength of the pulse by allowing some air to

bypass the modulator. With less air passing through the modulator, the pulse weakens and less

abrasive is fed into the air stream. The abrasive blend valve allows you to fine tune the abrasive

flow.

For more technical details on Simoom® Technology, see US patent #7,297,048.

Simoom

®

Technology

Содержание AccuFlo AF10-CE

Страница 1: ...Comco Inc 2151 N Lincoln St Burbank CA 91504 USA Tech comcoinc com 1 818 841 5500 ...

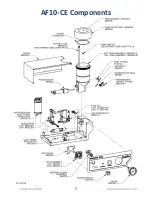

Страница 8: ...AF10 CE Components 1 818 841 5500 8 www comcoinc com ...

Страница 11: ...Tech Support 1 818 841 5500 11 tech comcoinc com AF10 CE Electrical Schematic Rev 12 7 21 ...

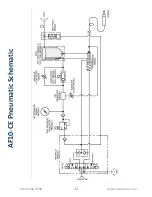

Страница 12: ...AF10 CE Pneumatic Schematic 1 818 841 5500 12 www comcoinc com ...