1‐818‐841‐5500

10

www.comcoinc.com

If the unit does not pressurize when you turn it on:

•

Is there power to the unit? Does the light on the power switch illuminate?

If not, check the power cord connections at the back of the unit and at the power source. Check

the fuse.

•

Is the air line connected? Are the upstream valves open?

Check the inlet air supply.

•

Do you hear air escaping from the unit when it is turned on?

Check that the inlet air, vent hose, and abrasive hose exiting the PowderGate® valve are

connected properly. See the set‐up guide on pages 4‐5. Make sure the tank cover is securely

fastened.

If air is passing through the nozzle, but no abrasive; or if the cutting action decreases:

•

Is the powder tank empty?

Refill.

•

Is the abrasive in the tank damp and sticking to the walls?

Replace with fresh powder. Check that your air dryer is working properly.

•

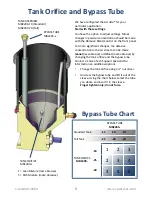

Is the tank orifice plugged?

Empty powder, remove orifice, and inspect. Check to see that your supplier of abrasive powder

is providing high quality material.

For details see the Support section on our website.

•

Is your modulator functioning properly?

You should hear a buzzing sound when the blast is activated. If not, the modulator may need to

be replaced. For further details contact Technical Support.

If nothing happens when the blast is activated:

•

Is the nozzle plugged?

Remove and inspect.

•

Is the PowderGate® valve failing to open?

Contact Technical Support.

If you suspect the PowderGate® valve is not closing completely:

When the PowderGate® valve closes, place a finger over the end of the nozzle for 3 seconds.

When you remove your finger – is there a small puff of air? If so, there are two possibilities:

•

The PowderGate® nose is worn and can be replaced as described above.

•

The abrasive mixture may be too rich. Reduce Abrasive Blend adjustment on front panel, or

check the Bypass Tube Chart for a leaner mixture to handle your nozzle size.

Troubleshooting

Contamination of the abrasive powder from

moisture and/or oil is one of the most

common problems associated with micro‐

abrasive blasting.

Moisture will cause the powder to “clump

up,” preventing it from flowing freely from

the tank.

Oil in the air supply will not only affect

abrasive flow, it can also cause major

component failures within your blaster,

resulting in costly repairs.

To avoid moisture and oil contamination, run

your air supply through a positive air dryer

equipped with an appropriate oil filter.

Prevent Moisture and Oil Contamination

Содержание AccuFlo AF10-CE

Страница 1: ...Comco Inc 2151 N Lincoln St Burbank CA 91504 USA Tech comcoinc com 1 818 841 5500 ...

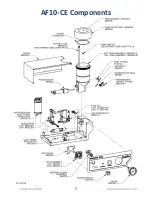

Страница 8: ...AF10 CE Components 1 818 841 5500 8 www comcoinc com ...

Страница 11: ...Tech Support 1 818 841 5500 11 tech comcoinc com AF10 CE Electrical Schematic Rev 12 7 21 ...

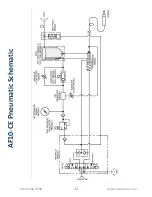

Страница 12: ...AF10 CE Pneumatic Schematic 1 818 841 5500 12 www comcoinc com ...