The Comco Warranty

Comco warrants that the AccuFlo® model AF10‐CE will be free from all defects in material and

workmanship under normal use for a period of one year from the date of purchase or 2,000 hours

of normal operation, whichever comes first.

The warranty period begins when the equipment ships from the Comco facility and applies to the

original owner only. Comco is not liable for damages from any cause or use of such equipment

beyond the cost of repairing any defective parts.

If the equipment fails to perform satisfactorily during the warranty period, Comco has the option

to do any one of the following: 1) Send replacement parts to the customer to be installed by the

customer; 2) Repair the unit at the customer’s facility; or 3) Request that the unit be returned to

the Comco factory. Any replacement parts shall be furnished by Comco without cost, F.O.B. the

Comco factory in Burbank, California, provided that Comco is notified of the defect within the

warranty period. Any defective parts shall be returned to Comco for inspection and analysis.

Exclusions

The above warranty does not apply to defects or problems resulting from improper or inadequate

maintenance by the customer; unauthorized modification or misuse; failure to follow the

operating instructions; the use of any supplies or parts, including but not limited to nozzles,

powders, and attachments, not manufactured or supplied by Comco.

The warranty also does not cover problems resulting from improper or inadequate facilities

(contaminated air; improper power) or items that should be expected to wear in normal

operation, such as nozzles, abrasives, tubing, or fittings.

This is Comco’s only warranty and is in lieu of all other warranties of merchantability and fitness

for any particular purpose. No representations or warranties are authorized except as herein

stated.

Always operate the AccuFlo® blaster in an

appropriate workstation with dust collection.

Never blast toward someone’s face or eyes. This

is a pressure device.

The Lexan window on the tank cover is abrasion

resistant. However, contact with certain chemicals

can weaken the cover and cause it to crack.

Inspect the cover daily and replace immediately if

cracks develop.

Refer to Comco Technical Support for full details

.

WARNING

MAXIMUM BLAST SETTING ON YOUR BLASTER

Never operate any micro‐abrasive blaster with

the air pressure regulator fully open. Check

your compressor settings to determine the air

pressure level it uses to trigger the re‐pressurize

cycle. The blast pressure setting on your blaster

should always be set at 10 psi below this point,

which is the lowest supply pressure coming

from your compressor. If the inlet pressure

drops below the blast pressure setting, air and

abrasive will flow backward through your

system and damage critical components.

Tech Support: 1‐818‐841‐5500

13

Содержание AccuFlo AF10-CE

Страница 1: ...Comco Inc 2151 N Lincoln St Burbank CA 91504 USA Tech comcoinc com 1 818 841 5500 ...

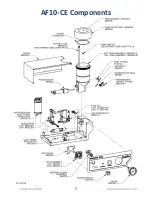

Страница 8: ...AF10 CE Components 1 818 841 5500 8 www comcoinc com ...

Страница 11: ...Tech Support 1 818 841 5500 11 tech comcoinc com AF10 CE Electrical Schematic Rev 12 7 21 ...

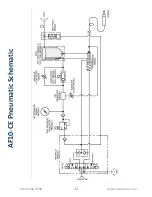

Страница 12: ...AF10 CE Pneumatic Schematic 1 818 841 5500 12 www comcoinc com ...