Page

41

of

47

NEPTUNE HQ

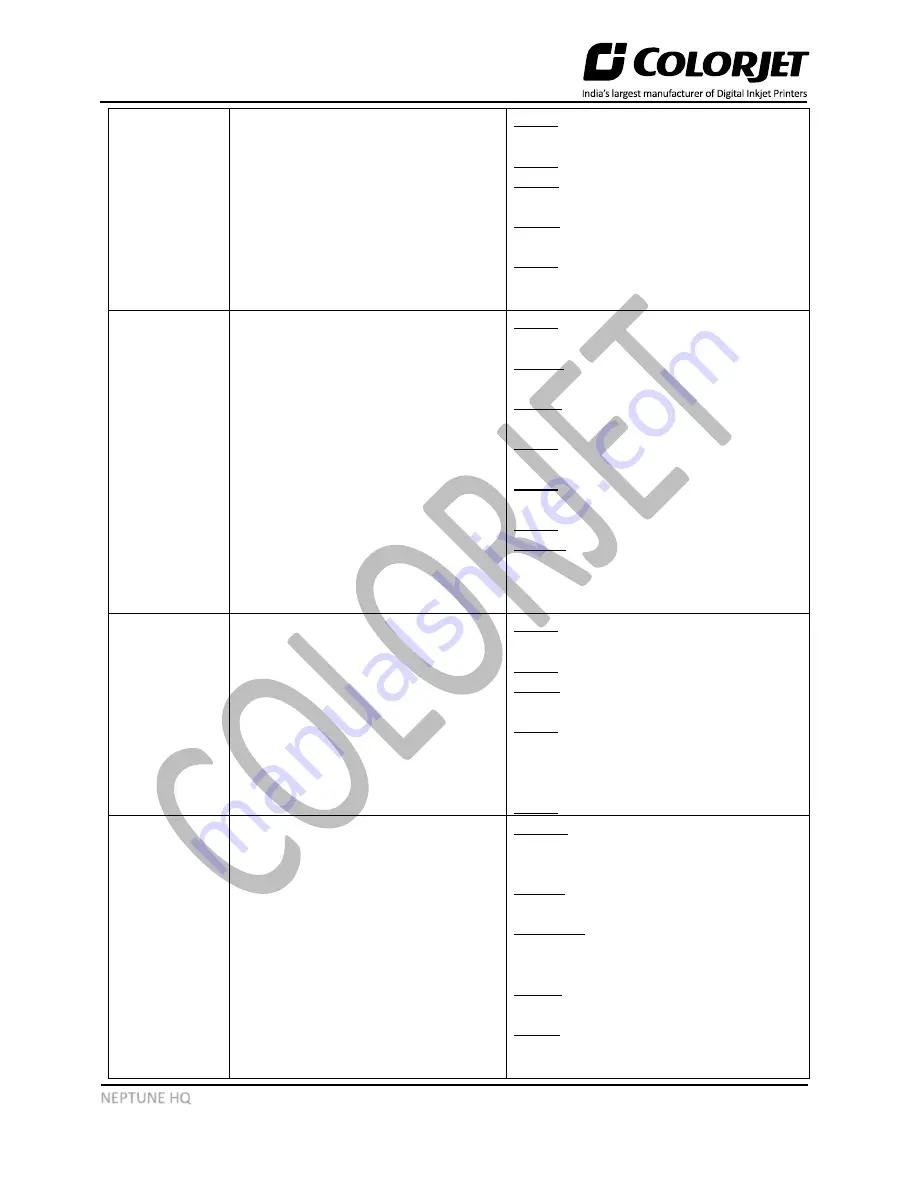

Printer

Manager Not

Showing

“Ready”

1.

USB

Cable

is

Loosely

Connected to the Printer

2.

USB Cable is Faulty

3.

Printer not Initialized

4.

USB driver is not Installed

5.

Main

Board

and

Head

Connector Board (HCB) is not

compatible (an error appears)

Case 1

: Tighten the USB cable.

Case 2

: Replace the USB cable, if faulty.

Case 3

: Please refer to the

“

PRINTER NOT

INITIAL

IZING”

section.

Case 4:

Please refer to the “

Installing the

Printer Manager

” section.

Case 5

: Kindly contact to the Head Office or

CES.

Carriage Stops

During Printing

1.

USB cable is loose or faulty

2.

Open heavy file that can slow

down the data transfer

3.

Ground wire is disconnected

4.

Encoder Scale is having ink

stains

5.

Pulley teeth wear out or belt is

slipping

6.

Ripped file is having error

7.

Check I/P and O/P voltage in

24V SMPS on full load. Voltage

drop, if any.

Case 1

: Tighten the USB cable or replace it,

if required.

Case 2

: Use compatible and small size

images for printing.

Case 3

: Connect the ground wire to the

system.

Case 4:

Check and Replace Encoder Scale

Case 5

: Replace the Pulley or Carriage Belt

Case 6

: Correct the ripped file error, if any.

Case 7:

Replace the power supply, if

voltage drop is found and also check the

power Inlet to the machine.

Print Margin Is

Shifting Or

Junk Printing

1.

Encoder Scale is having ink

stains

2.

Encoder Sensor is not clean

3.

Pulley or belt is slipping

4.

Data cable is faulty (Steps)

5.

Main Board is faulty

Case 1:

Clean the Encoder Scale.

Case 2:

Clean the Encoder Sensor.

Case 3:

Check for any wear & tear in the

pulley or belt and replace it, if required.

Case 4:

Check by swapping the direction of

data cable and replace it, if required. The

data cable is connected between Head

Board and Main Board.

Case 5

: Replace the Main Board, if faulty.

Print Is Blur

(Not Sharp)

1.

Improper Head height

2.

Improper head alignment

3.

Recommended ink not used

4.

Ink stored at unfavorable

environment

5.

Head voltage is not properly

fed in Printer Manager

6.

Improper step calibration

Case 1

: Correct the head height by

following the steps given in the

Head

Height Adjustment

section.

Case 2

: Calibrate the printer again by

referring the “

Head Alignment”

section.

Case 3 & 4

: Use only the recommended ink

and stored it in favorable environment

conditions.

Case 5:

Feed the Head Voltage value as

mentioned in the Print Head.

Case 6:

Correct the step calibration using

the Step Calibration section.