46

47

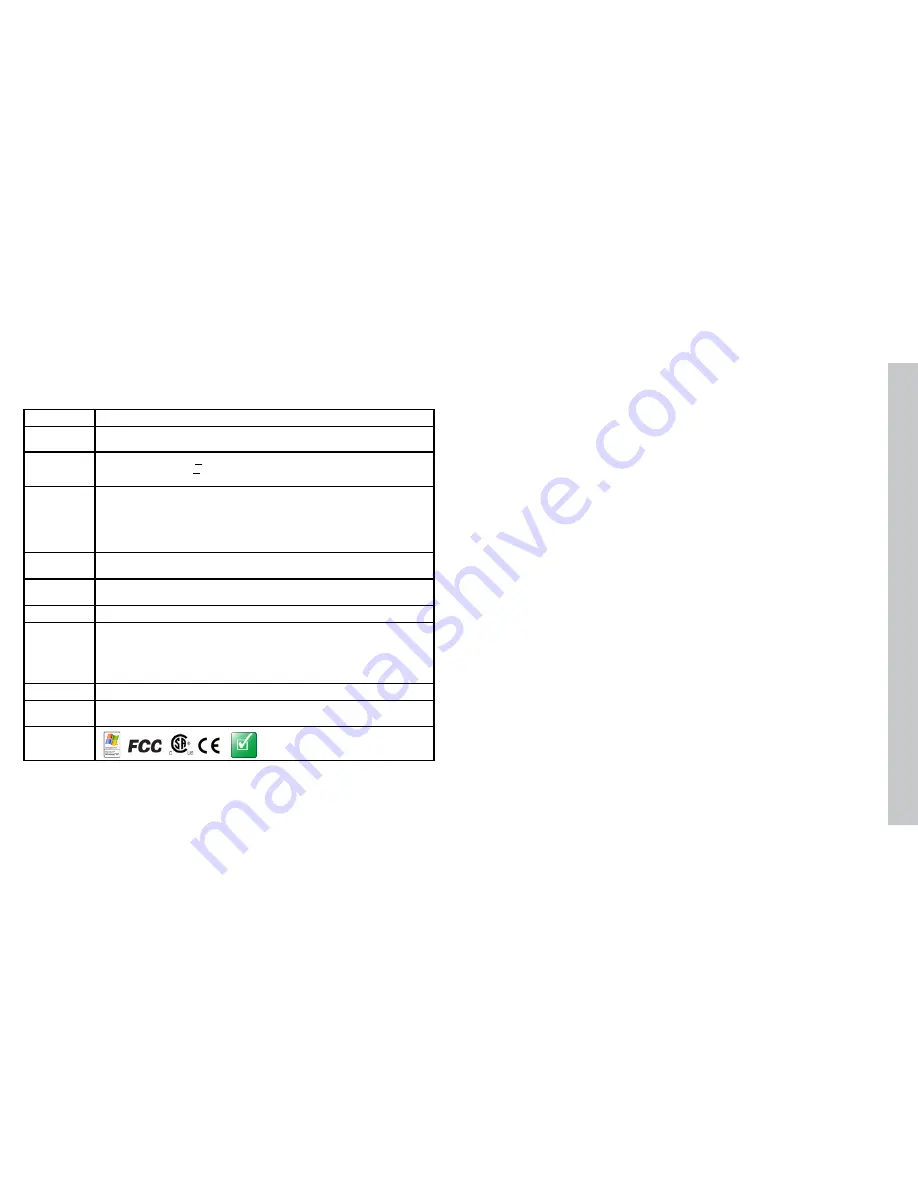

Specifications

Cable

24AWG, 5 m, M12 connector (power and I/O)

Power require-

ments

Voltage:

+24 VDC (22-26 VDC)

Current:

250 mA max

Discrete

Inputs

Input ON:

> 10 VDC (> 6 mA)

Input OFF:

< 2 VDC (< 1.5 mA)

Protection:

Opto-isolated, polarity-independent

Discrete

Outputs

Output:

Solid state switch

Rating:

100 mA, 24 VDC Max

Max voltage drop:

3.5 VDC @ 100 mA

Max load:

100 mA

Protection:

Opto-isolated, protected from short circuit, overcurrent, and

reverse polarity.

24V power

fuse

500 mA, 60 V rated resetable fuse that will recover after an overload is re-

moved. Protects against over voltage and reverse wiring.

Output fuse

200 mA, 30 V rated resetable fuse that will recover after an overload is re-

moved. Protects each output from over current.

Weight

3.5 oz. (100g)

Environmental

limits

Operating temperature: 32° to 122°F (0° to 50°C)

Storage temperature: -22° to 176°F (-30° to 80°C)

Operating humidity: 0% - 90% non-condensing

Maximum operating altitude: 4000 meters

Protection: IP67

Pollution degree: 2

Shock

80Gs for 5ms on each axis (per IEC 68-2-2)

Vibration

10Gs (10-500Hz) at 100 M/sec2 / 15mm for 2 hours in each axis (per IEC 68-

2-6)

Certification

RoHS

Precautions

Observe these precautions when installing Checker to reduce the risk of injury or equipment

damage:

Do not use Checker in applications where an incorrect or absent output signal

•

could cause human injury.

Checker is intended for indoor use only.

•

Do not attempt to adjust Checker’s focus when moving parts and/or equipment are pres-

•

ent.

Use a listed power supply with an output rated 24 VDC, at least 250 mA, and marked

•

Class 2, Limited Power Source (LPS). Any other voltage creates a risk of fire or shock and

can damage Checker.

Connect the cable shield to earth ground.

•

Make sure that no voltage potential exists between the USB ground on the PC and the

•

Checker chassis ground.

An IP67-compliant plug or cable must be fitted to the USB connector for Checker to meet

•

the IP67 protection standard.

Do not install Checker in locations that expose it to environmental hazards such as

•

excessive heat, humidity, impact, vibration, corrosive substances, flammable substances,

or static electricity.

To reduce the risk of damage or malfunction, route all cables and wires away from high-

•

voltage power sources.

Do not extend I/O and power cables longer than 30 meters.

•

Make sure that the mounting screws do not bottom in the mounting holes; using too long

•

a mounting screw can damage Checker.

Do not attempt to modify Checker. Modifications will void the warranty.

•

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules These limits are designed to provide reasonable protection against harmful interference when the equipment is operated

in a commercial environment This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense

Copyright © 2009 Cognex Corporation All Rights Reserved This document may not be copied in whole or in part, nor transferred

to any other media or language, without the written permission of Cognex Corporation Cognex, the Cognex logo, Checker, and the

Checker logo are trademarks, or registered trademarks, of Cognex Corporation

This product is covered by one or more of the following US patents and one or more pending US and foreign patents, which, when

issued are listed on the Cognex web site at http://www cognex com/patents

5583954, 5602937, 5964844, 6215915, 6381375, 6421458, 6931602, 7305114, and 7417803

Содержание Checker 3G Series

Страница 1: ...COGNEX Checker 3G Series User s Guide...

Страница 25: ...COGNEX 590 7096...