CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Tranquility

®

(TRL) Series

R e v. : N o v e m b e r 1 1 , 2 0 2 1

C l i m a t e M a s t e r Wa t e r-S o u rc e H e a t P u m p s

64

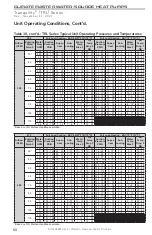

Functional Troubleshooting

Fault

Htg Clg Possible Cause

Solution

Main power

problems

X

X

Green Status LED Off

Check line voltage circuit breaker and

disconnect.

Check for line voltage between L1 and L2 on

the contactor.

Check for 24VAC between R and C on

CXM2.

Check primary/secondary voltage on

transformer.

HP Fault

Code 2

High Pressure

X

Reduced or no water flow

in cooling

Check pump operation or valve operation/

setting.

Check water flow adjust to proper flow rate.

Check flow switch is operating correctly.

X

Water Temperature out of

range in cooling

Bring water temp within design parameters.

X

Reduced or no air flow in

heating

Check for dirty air filter and clean or replace.

Check flow switch is operating correctly.

Check fan motor operation and airflow

restrictions.

Dirty Air Coil- construction dust etc.

Too high of external static. Check static vs

blower table.

Confirm wire harness connection to correct

taps.

X

Air temperature out of range

in heating

Bring return air temp within design

parameters.

X

X

Overcharged with refrigerant

Check superheat/subcooling vs typical

operating condition table.

X

X

Bad HP Switch

Check switch continuity and operation.

Replace. Confirm wire harness connection to

correct taps.

LP/LOC Fault

Code 3

Low Pressure /

Loss of Charge

X

X

Insufficient charge

Check for refrigerant leaks.

X

X

Bad LP switch

Check switch continuity and operation.

Replace.

Check if JW3 is cut on CXM2 to avoid

system looking for the incorrect LP switch.

X

Compressor pump down at

start-up

Check charge and start-up water flow.

LT1 Fault

Code 4

Water coil low

temperature limit

X

Reduced or no water flow

in heating

Check pump operation or water valve

operation/setting.

Plugged strainer or filter. Clean or replace.

Check water flow adjust to proper flow rate.

Check flow switch is operating correctly.

X

Inadequate antifreeze level

Check antifreeze density with hydrometer.

X

Improper temperature limit

setting (25°F vs 10°F [-4°C

vs -12°C])

Clip JW3 jumper for antifreeze (10°F [-12°C])

use. Check flow switch is operating correctly.

X

Water Temperature out of

range

Bring water temp within design parameters.

X

X

Bad thermistor

Check temp and impedance correlation per

chart.

Table continued on next page.