MEDIPULSE 2342se ERGONOMIC SUCTION BLAST CABINET

Page 7

© 2019

CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 24939, Rev. C, 03/19

2.5

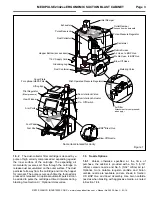

Set Air-Inlet Damper ‒ Figure 6

2.5.1

The inlet damper must be set to match the

cabinet dimensions and reclaimer size. The label on the

damper shows the settings in degrees. For the initial

setting, align the handle 30 degrees.

Figure 6

2.5.2

Loosen the lock nuts and position the damper

handle as noted. When correctly positioned, tighten the

lock nuts to maintain the setting. Refer to Section 5.7 for

adjustment procedure.

2.6

Final Assembly

2.6.1

Position the foot pedal on the foot shelf or on the

floor at the front of the cabinet. The foot shelf is easily

removed by removing the two release pins.

2.6.2

A package of five cover lenses is supplied with

the cabinet. To install a cover lens, remove the adhesive

backing and apply the lens to the clean, dry, inner

surface of the view window. Refer to Section 7.3. When

the cover lens becomes pitted or frosted, replace it.

3.0

FIELD INSTALLED ACCESSORIES

3.1

Aluminum Oxide (aggressive media) Kit

3.1.1

An optional aluminum oxide kit is available

factory installed or may be field installed later.

Factory-installed kits consist of black-rubber cabinet

curtains with grommets, curtain hardware, and a boron

carbide nozzle.

Field-installed (or replacement factory installed) kits

consist of black-rubber cabinet curtains (refer to Section

3.2 for curtain installation) a boron carbide nozzle, and

light-lined flex hose. If the existing flex hose is in good

condition, reserve the new hose for future replacement.

3.2

Cabinet Curtains Installation

3.2.1

Match curtains to corresponding wall and doors.

3.2.2 Front and rear walls:

Position the curtain on

the wall to be protected. Using the curtains as templates,

mark each mounting point through the grommet holes

along the upper edge of the curtain. NOTE: When laying

out the attachment points, the upper edge of the rear

curtain should be below the bottom edge of the air-duct

partition. Remove the curtains and drill a .187" (3/16")

diameter hole at each point marked. Install the curtains

using the fasteners provided (machine screw, 11/16

OD

flat washer, lock washer and nut) at each grommet. The

flat washer is used between the screw head and the

rubber curtain grommet on all curtains.

3.2.3

Doors:

Using protectors against the curtains

and outer doors, clamp the door curtains in place.

NOTE: When laying out the attachment points, the upper

edges of the door curtains should be even with the outer

edges of the door’s soundproofing panel. Insert a #10

self-drilling screw with an 11/16

OD flat washer through

the grommet holes. Use a screw gun with a 5/16" socket

to drill and thread the screws through the door’s inner

wall at each grommet.

3.3

Track and Low-Profile Table,

Maximum Weight Capacity 500 Lbs

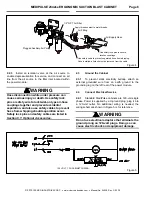

3.3.1

Components of track and table assembly are

shown in Figure 7. The assembly consists of:

1. Track assembly: mounts inside the cabinet.

2. Table assembly: rollers on sliding table fit inside the

track rails.

3. All necessary mounting fasteners.

Figure 7

NOTE: The track may be installed on either side of the

cabinet, so the table can slide out through either the

Damper Handle

Degrees Label

Align handle to degrees, as

noted in Paragraph 2.5.1.

Air-Inlet Damper

Table Assembly

Track Assembly

Mounting Holes

Mounting Holes

Rollers (4)

Track Rails