MEDIPULSE 2342se ERGONOMIC SUCTION BLAST CABINET

Page 14

© 2019

CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 24939, Rev. C, 03/19

5.5.3

Loosen the actuator bracket screws and

adjusting screw nut. Move the actuator bracket up or

down, and the adjusting screw sideways, as needed to

center the adjusting screw on the over-travel stop (in

center of detent sleeve). Tighten the bracket screws.

5.5.4

Turn the adjusting screw in or out as required to

engage the switch without applying excessive pressure

on it. Tighten the adjusting screw nuts.

5.5.5

Test the operation with the doors open and then

again closed. Negative pressure inside the cabinet may

cause the doors to flex inward. Tests should be

performed with the exhauster running. Point the nozzle

away from the door during the tests, and open the door

only enough to disengage the interlock switch. The

interlocks should stop the blasting when either door is

open and permit blasting when the doors are closed.

5.6

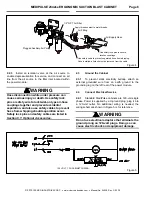

Pulse Pressure ‒ Figure 19

NOTICE

Do not pulse new dust collectors or

replacement cartridge until the cartridge is

properly seasoned, per Section 7.10. Pulsing

unseasoned cartridges can decrease the

efficiency of dust collectors and cause

premature cartridge failure.

5.6.1

Adjust pulse pressure using the regulator

mounted on the pulse reservoir (refer to Figure 19).

Begin pulse at 60 psi. To adjust pressure, pull the knob

to unlock it, as shown in Figure 19, and then turn

clockwise to increase pressure or counterclockwise to

decrease pressure. Once operating pressure is set,

push the knob to lock it and maintain the setting.

Figure 19

5.6.2

As the filter cartridge cakes with dust, it may be

necessary to pulse between blasting, per Section 6.2.4.

5.6.3

When pulsing alone does not adequately clean

the cartridge, increase pulse pressure in increments of 5

psi until the maximum of 90 psi is reached. As dust cakes

on the cartridge, the differential pressure increases.

Using a gauge to measure the differential pressure is a

good way to tell if the cartridge is heavily caked.

5.6.4

When the maximum pulse pressure of 90 psi is

attained, and additional pulsing as described in Section

6.2.4 does not increase visibility or decrease differential

pressure, replace the cartridge, per Section 7.9.

5.7

Cabinet Air-Inlet Damper

5.7.1

Once the damper is initially set, per Section 2.5,

it seldom requires readjustment. The initial setting

produces approximately .5

to .75

of static pressure in

the cabinet enclosure.

Do not confuse cabinet static

pressure with reclaimer static pressure, which is

controlled by the outlet damper, as noted in Section

5.4. Reclaimer pressure must be set before cabinet

pressure.

5.7.2

Using a manometer (as noted in Section 5.8 and

listed in Section 9.1) is the most accurate method of

monitoring and adjusting cabinet pressure. Following the

instructions packed with the manometer, start the

exhauster and insert the needle into a glove, and adjust

pressure using the inlet damper. Open the damper

further to decrease static pressure or close it further to

increase pressure.

5.7.3

If a manometer is not available, use the gloves

as an indicator. With the exhauster ON, the gloves

should be inflated, but not elevated off the grate.

5.8

Optional Manometer

NOTE: These instructions show several methods of taking

static-pressure readings (negative pressure) on MediPulse

Reclaimers by using a flexible-tube manometer. Use the

method best suited for the application. The instructions

explain the processes for taking periodic readings and

show how to permanently install the manometer for taking

frequent readings. Permanent fittings should be installed

when the manometer installation is permanent. Use

silicone sealer or other sealant to seal around the fitting to

prevent leaks. The fitting should be capable of being

capped when the manometer tube is removed. This will

prevent leaks that alter the reclaimer’s separation

efficiency. Taking readings at different locations could

produce different readings. Static-pressure readings at the

door are generally 0.5" to 1" lower than reading taken

above the reclaimer. The readings are reference points,

so readings should be taken using the same method each

time the reading is taken.

Pulse Regulator

Mounted on pulse reservoir.

Adjustment Knob

Pull knob up to unlock

and adjust pressure.

Push down to lock.