86c_Wartung en bedingt.fm, 24.07.2008

P1886E/EN 2008-07

17

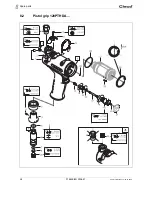

Maintenance

6

1.

Remove the threaded pin

15

and ball

14

.

2.

Remove the O-ring

12

and sleeve

13

.

3.

Align the output drive and claw as shown in the illustration, see 6.2 Activating the reserve

oil, page 15.

4.

Rotate the equalizing piston

11

clockwise as far as it will go until

X

= 0 (starting point).

5.

Unscrew the equalizing piston

11

counterclockwise by 1,0 turns (reserve oil volume).

6.

Connect the pulse unit

8

to the quick disconnect coupling

5

using the adapter.

7.

Close the shut-off valve

7

.

8.

Set the working pressure to approx. 73 psi (500 kPa).

9.

Slowly open the shut-off valve

7

all the way until the

gauge shows a negative pressure of –13 psi (–90 kPa).

10. Wait approx. 2 minutes until the number of vacuum bubbles has reduced significantly.

11. Close the shut-off valve

7

slowly. The gauge shows atmospheric pressure again. Missing oil

is pushed into the pulse unit

8

.

12. Repeat steps 8 through 11 if necessary until the number of bubbles approaches zero.

13. Uncouple pulse unit

8

, unscrew the adapter and add a couple of drops of oil using the injec-

tor.

14. Mount the ball

14

and screw the threaded pin

15

into place (0.75+0.25 ft lbf, or 1 +0.3 Nm).

15. Turn the equalizing piston

11

another 2,5 turns counterclockwise, or slightly more if neces-

sary, until the sleeve

13

can be inserted (oil compensation volume).

16. Install the sleeve

13

and O-ring

12

.

NOTE

Small air bubbles that become visible due to the high pressure during filling do not mean that the

pulse unit is leaking.

The filling process is not impaired.