86c_Wartung en bedingt.fm, 24.07.2008

P1886E/EN 2008-07

13

Maintenance

6

6

Maintenance

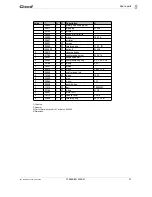

6.1

Service schedule

Regular maintenance reduces operating faults, repair costs and downtime.

This maintenance schedule uses values that are valid for most applications. For a specific ser-

vice interval, see 6.1.1 Calculating a customer-specific maintenance plan, page 14.

Implement a safety-related maintenance program that takes the local regulations for repair and

maintenance for all operating phases of the tool into account.

CAUTION!

Danger of injury due to unintentional activation

– before service, disconnect the tool from the compressed air supply.

Mainte-

nance

interval

Rundowns

Measures

W1

100,000

➔

Check the suspension bail for functional safety.

➔

Check the air hose for wear.

➔

Check the square on the output drive for wear.

➔

Check the air inlet for tight fit.

➔

Check the housing of the pulse unit for tight fit.

➔

Check the max. free speed.

W2

500,000

➔

Oil change, see 6.3 Refilling oil, page 16.

➔

Motor service kit, see 3) Part of motor service kit K1,

order no. 935653, page 27.

➔

Hydraulic service kit, see 3) Part of hydraulic service

kit K2, order no. 935654, page 33.

➔

Replace muffler, filter.

W3

1,000,000

Check individual parts and replace if necessary.

➔

Suspension bail

➔

Throttle valve

➔

Exhaust air throttle

➔

Motor

➔

Pulse unit