9

the sprocket at the base of the column enters the opening in the base cleanly, without touching

the sides, (as this could damage the sprocket).

Ensure also that the cable, which protrudes from the channel, welded to the columns’ bottom plate

(shown in fig. 4), is not trapped between the plate and base.

Secure to the Base Frame using the four screws, and large flat washers provided,in the corner bolt

holes ONLY, leaving them finger tight at this stage.

DO NOT use the centre holes

.

Carry out the same procedure for the other column.

Place Chocks here

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

1234567890

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Fig. 5

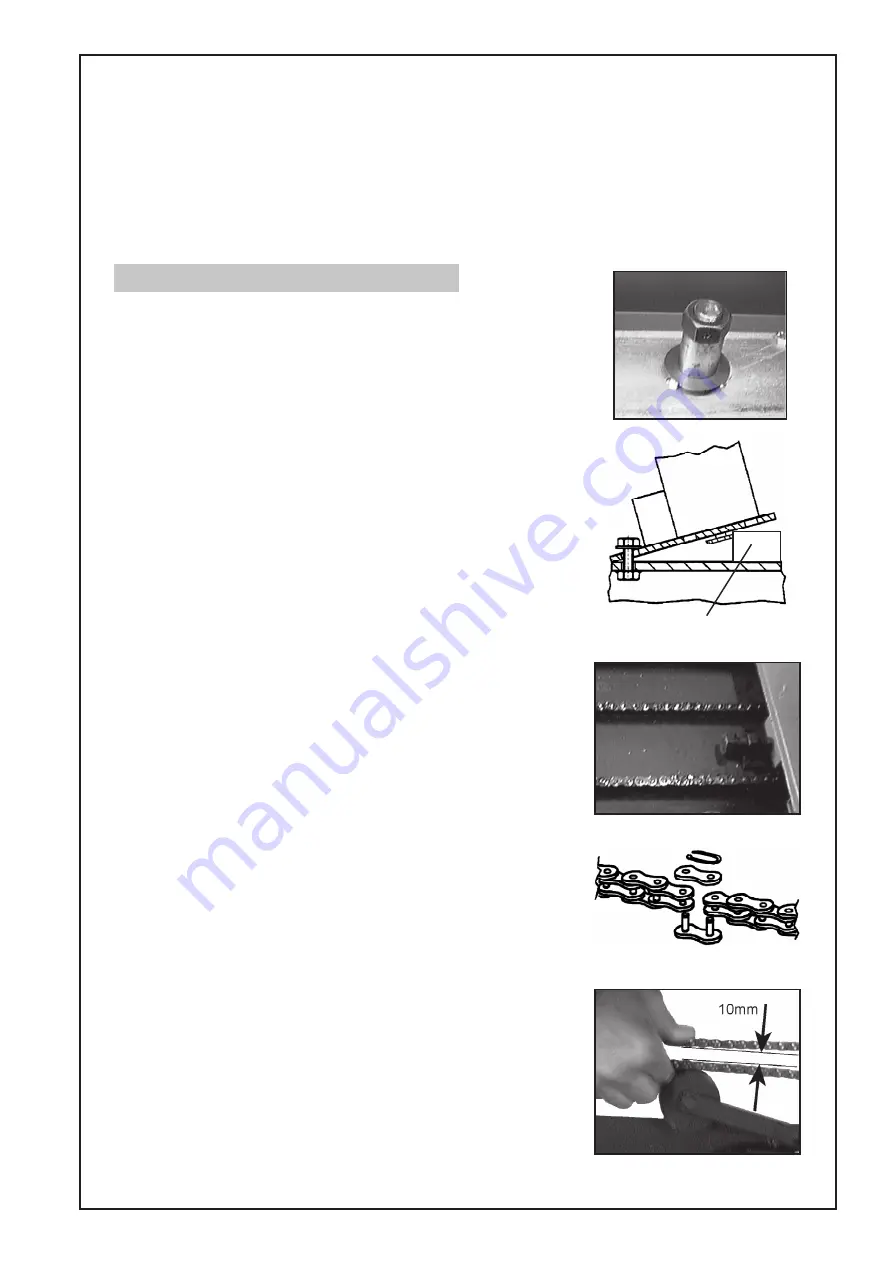

3. THE CHAIN

3.1 Before attaching the chain, you must first ensure the Arm

Carriages are at the same height, measured from the columns’

Base Plate. If an adjustment is required, remove the dust cover

from the top of the Driven column and turn the hex. nut (on top

of the column, shown in fig. 5),until the carriage is perfectly in

line with that of the Drive Column. Replace the Dust Cover

3.2 Remove all but the two ‘outside’ column mounting screws and

slacken these off sufficiently so that the column may be tilted

outwards (see fig.6), in order to allow the chain to be slipped

around the sprocket.

Before tilting the column outwards however, slacken off the chain

adjuster screw, shown in fig. 7, fully, and make sure the column is

pushed in, towards the opposite column, as far as possible.

3.3 Very carefully tilt the column outwards and, as a safety

precaution, place chocks between the columns’ Base Plate

and the Base Frame as shown in fig. 6. (Should the column slip,

the chocks will prevent the column from injuring the hands of

the person manipulating the chain.

3.4 Slip the chain around the sprocket so that the end of the chain

reaches approximately half way across the Base Frame.

3.5 Once the chain is connected, remove the chocks, lowe the

column and screw down the column mounting screws again,

leaving them finger tight.

3.6 Proceed to connect the chain to the sprocket in the other column in

a similar manner,ensuring that the run of chain, from one sprocket

to he other, is as tight as you can get it,

without

turning the sprocket,

(as this will cause the carriages to become missaligned).

3.7 The two ends of the chain can now be brought together and

joined using the quick coupling provided (fig.8).

3.8 Once the chain is in place, it must be adjusted by screwing the

adjuster screws, (fig. 7), clockwise.

Screw in each adjuster, in turn, by a similar amount - say ½ turn

each side, until the gap at the centre, between the two runs of the

chain, is 10mm when using reasonable force of the thumb and

forefinger of one hand only. (see fig.9).

This microswitch is a safety feature, and operates when the

chain becomes too slack (less than 10mm gap at the centre of

the run), or breaks, shutting off the power to the motor.

3.9 Finally, connect the two electric cables, one from the base of

each Column, to the leads from the microswitch, using the two

waterproof in-line connectors packed in the parts bag.

Trim the cables back so that there is as little slack in the cable as

possible, to prevent any possibility of the connector, or the

cable, coming into contact with the chain.

Содержание Strong-Arm CPL30S

Страница 1: ...1 2 POST VEHICLE LIFT Model Nos CPL30S CPL30T OPERATING MAINTENANCE INSTRUCTIONS 0201...

Страница 2: ...2 Copyright Clarke International July 1999 All rights reserved...

Страница 21: ...21...

Страница 22: ...22...