7

WARNING:

NEVER press the spindle lock button when starting the tool, and

NEVER press the button when the tool is operating.

DO NOT press thebutton until the wheel/disc has stopped completely

ASSEMBLY

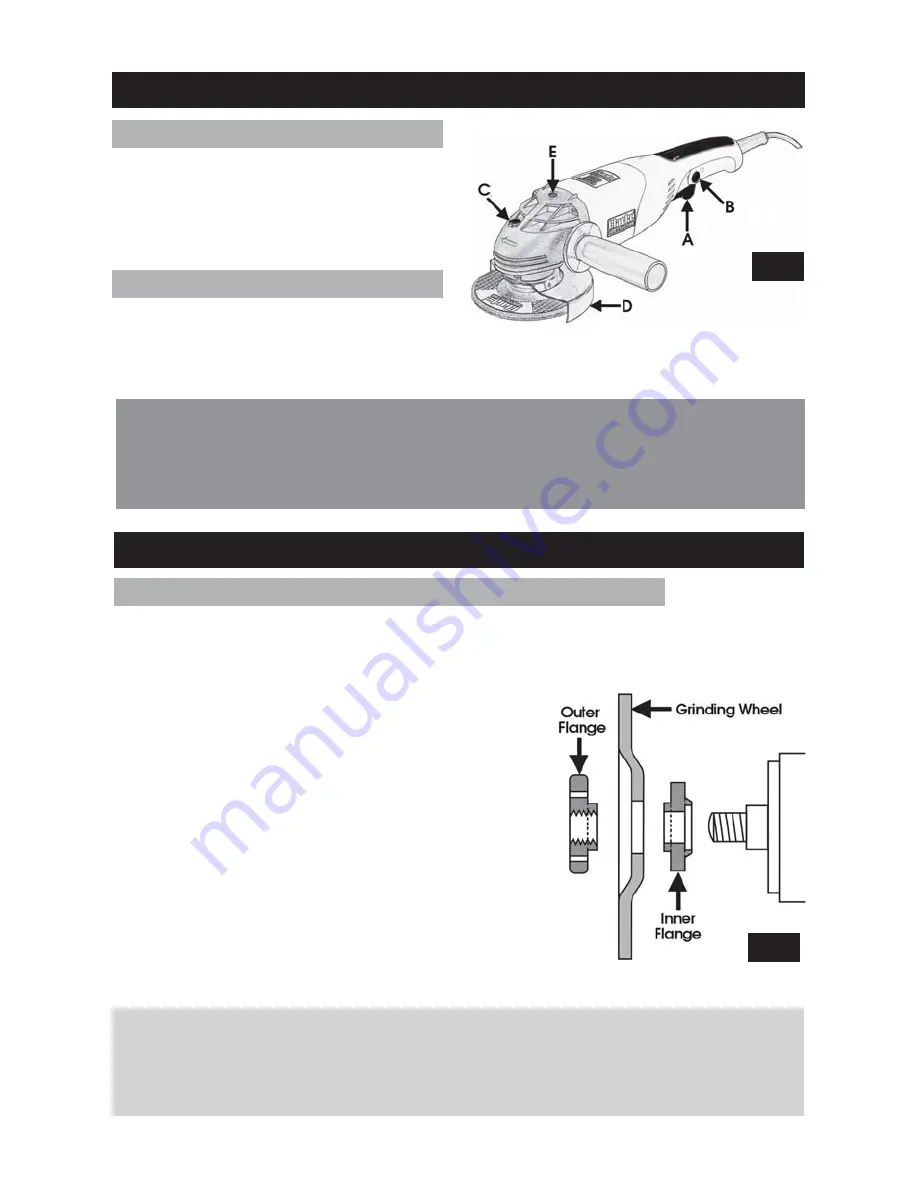

1. Mounting the Grinding Wheel/Cutting Disc

Fig 1.

FEATURES

(Ref. Fig 1)

1.1

Unscrew and remove the outer flange by locking

the spindle using the Spindle Lock button then

usethe flange tool supplied to turn the flange (right

hand thread). It may then be screwed off by

hand.

1.2 The grinding wheel supplied is the ‘Depressed

Centre’type. Mount it as shown in the Fig.2. i.e.

with the depressed centre towards the motor

1.3 Ensuring the wheel sits snugly over the raised boss on

the inner flange, screw on the outer flange with the

centre boss facing inwards.

1.4 Tighten the flange using the tool provided, locking

the spindle by pressing the Spindle Lock button,

andtaking care to ensure the wheel is still sitting

snugly,centred over the flange bosses. Care should

be taken also NOT to overtighten the outer flange.

1. ON/OFF Switch (A)

The ON/OFF switch (A) is provided with a safety

lock button (B). The lock button (B) must be

held in before the trigger can be squeezed in

to the ‘ON’ position. This is designed to prevent

accidental starting.

.

2. Spindle Lock Button (C)

WARNING:

Fig 2 shows the set up for a grinding wheel.

When attaching a cutting or diamond disc YOU MUST REVERSE the outer

flange so that the boss faces OUTWARDS.

Ensure the grinder is disconnected from the mains supply.

Fig 1.

Fig 2.

When pressed, this button, located on top

of the head, is used to lock the spindle

when attempting to unscrew and remove the outer flange (using the special tool

provided), in order to mount or change the grinding wheel or cutting disc.