18

3. An appropriate current must then be set by turning the Welding Current Selector

located on the front panel o the machine. With practice you will gain a feel for the

correct current setting for different welding rod thicknesses.

The size (diameter) of welding rod should be approximately the same as the

thickness of metal to be welded.

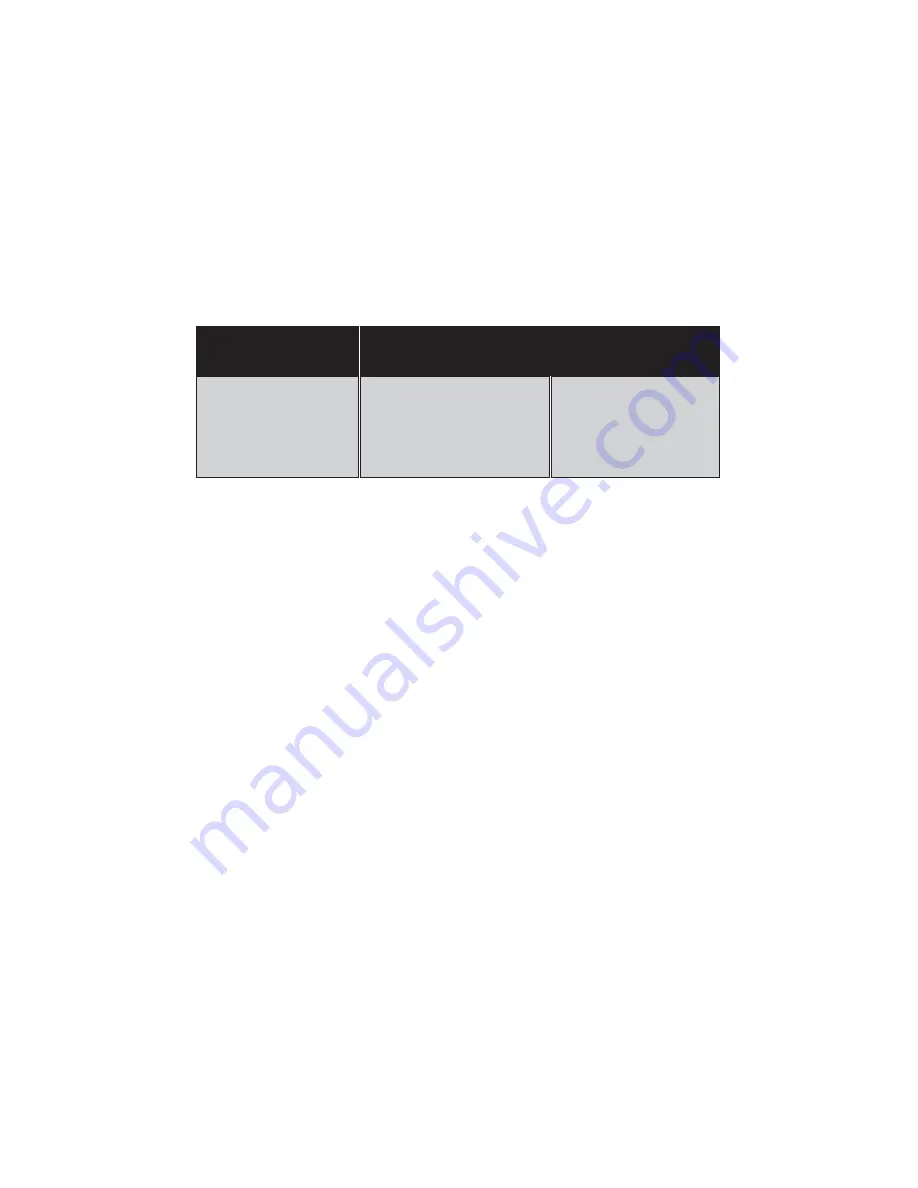

For beginners, the following table gives some useful guidelines.

SIZE OF

THICKNESS

CURRENT

WELDING ROD

OF WORKPIECE

SETTING (AMPS)

1.5mm

16 SWG - 1.5 MM.

30 - 40

2.0mm

14 SWG - 2.0 MM.

50 - 65

2.5mm

12 SWG - 2.5 MM.

70 - 100

3.0mm

10 SWG - 3.25MM

100 - 130

4.

Switch ON using the switch located on the rear panel. The green light on the

front panel should glow, indicating the machine is ON.

Note: If the machine stops at any time and the amber light comes ON the

thermal overload has intervened

5. The most difficult aspect of the arc welding process, particularly for beginners,

is that of striking an arc. We strongly recommend that you practice on some

pieces of scrap metal to get the feel of the operation, before you start on an

actual welding job.

6. Hold the electrode about 10mm. from the work and at an angle of about

70

°

to 80

°

to the work surface; take care not to accidentally touch the workpiece

until you are ready to commence.

7. Holding the welding mask close-up to the face, give a short stroke with the

electrode on the workpiece. As soon as the arc is primed, withdraw the

electrode from the workpiece to leave a tiny gap of around 1.5mm (1/16").

The current will flow across the gap with a crackling noise and brilliant arc.

Continue to weld in one direction, maintaining the small gap as you go. At

the end of the run just withdraw the electrode fully from the workpiece.

Note: When you prime the arc be sure to withdraw the electrode fairly swiftly

to leave the 1.5mm. gap, otherwise the electrode will weld itself to the

workpiece. Should this occur give the electrode a short sharp jerk to free it

and, if necessary prime the arc again. If you cannot free the electrode, switch

the machine off immediately, and free it off.

8. Inspect the job carefully. With a correct combination of rod size and current

setting, the area of the weld should be a complete fusion of the electrode

metal with the metals being joined. Slag forming on the surface should be

chipped away with a chipping hammer or pick. ALWAYS wear your safety

goggles when chipping away slag.

Содержание 6012200

Страница 23: ...PARTS DIAGRAM ARC TIG 85 110 23...

Страница 24: ...PARTS DIAGRAM ARC TIG155 24...

Страница 25: ...25 WIRING DIAGRAM ARC TIG155 ARC TIG 85 110...

Страница 28: ......