Example:

If the loop contains 2500L, comprising EG30%, for a unit with 6

Free Cooling coils, then it is necessary to add 30L (2500*1.2%)

of corrosion inhibitor every 8 years.

The corrosion inhibitors to be used are dipotassium hydrogen

phosphate type inhibitors. Only use products compatible with

aluminium. It is not recommended that the glycol is diluted to obtain

the desired concentration, so as to not reduce the original quantity

of corrosion inhibitors.

Formula equivalent to table 1 ► X = (V*P) / (1578*N)

-

X = Number of years between two corrosion inhibitor top-ups

-

V = Total volume in the loop (litres)

-

P = Glycol concentration (%)

-

N = Total number of Free Cooling coils connected to the water

loop

Formula equivalent to table 2 ► I = (V*P) / 2500

-

I = Volume of inhibitor to be added after X years (litres)

-

V = Total volume in the loop (litres)

-

P = Glycol concentration (%)

Protection against fouling:

The brine loop must be clean. To ensure the exchangers are able

to operate correctly, it is recommended that a sludge container,

settling container, or another filtration system is also installed

upstream of the unit, if necessary.

Frost protection

To prevent the risks of freezing when operating in low temperature

environments, the units equipped with the Free Cooling option

must be protected with a glycol-based solution, see Freezing curve

for Ethylene and Propylene glycol (section 12.2.1). The unit is

delivered without glycol. When filling with glycol, ensure that the

two motorised valves are open, along with the manual valve, to

guarantee that the glycol is correctly distributed within the unit.

If the customer loop requires testing or flushing, ensure that the

Free Cooling circuit valve is closed to prevent water from returning

to the Free Cooling micro-channel coils.

If water is introduced, drain the unit using the drain screws placed

on each coil and the drain taps at the low point in the Free Cooling

manifolds. Then add a glycol-based solution to protect the unit

from freezing.

NOTE: If the manufacturer's recommendations are not

respected, there is a risk of damage to the equipment.

The use of fresh water is prohibited with the Total and Partial

Free Cooling option.

Free cooling pipes

The maximum operating pressure for the total and partial Free

Cooling option is 6 bar. The nominal value is indicated on the unit's

name plate.

The manual valve installed on the unit's Free Cooling loop must

always be in the open position, except during draining or

maintenance.

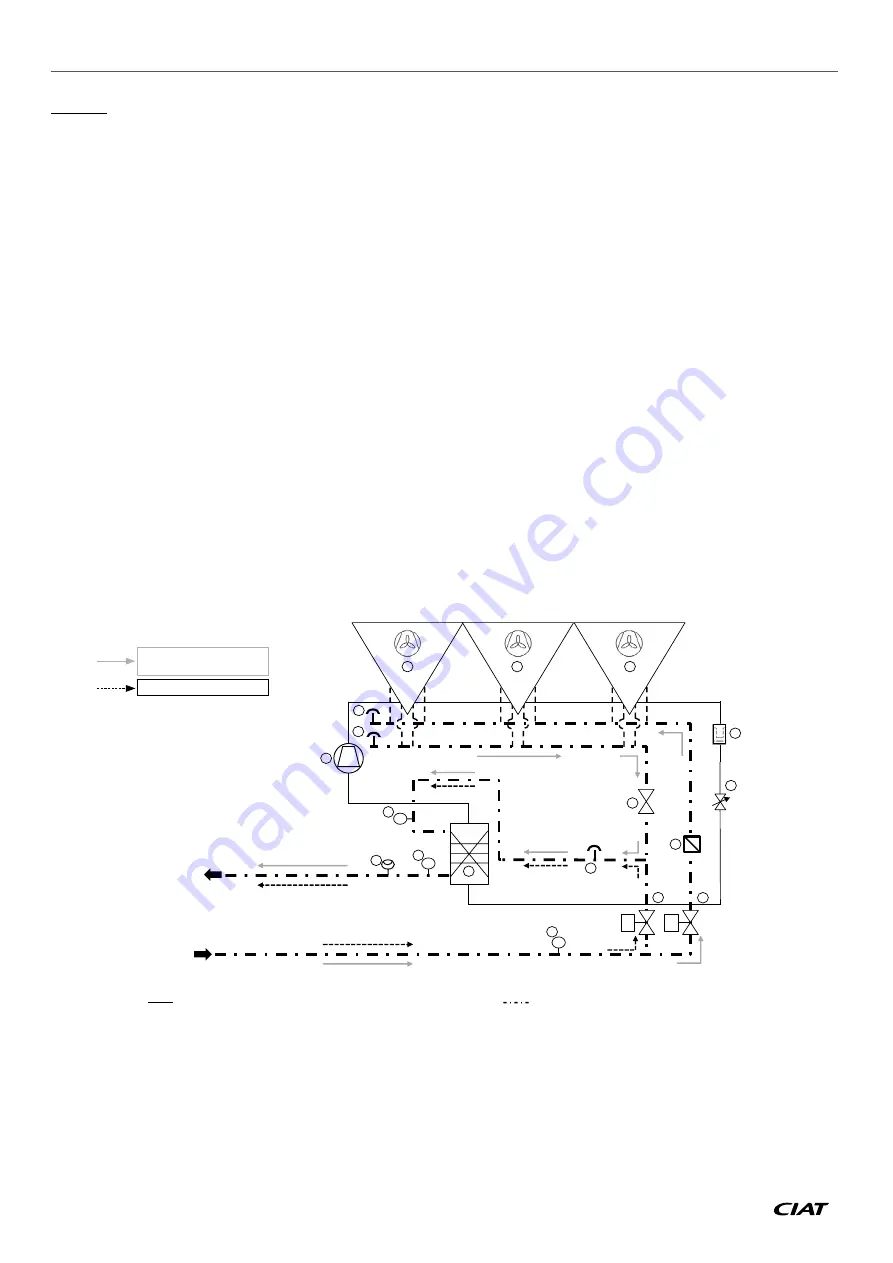

12.2.11.4 - Installation and hydraulic connection

Circulation diagram

T

T

2

4

5

7

7

9

8

7

9

T

10

6

M

6

11

1

M

9

3

3

3

- Free Cooling mode

- Combination mode

- Mechanical cooling mode

Refrigerant circuit:

Water circuit:

B

Evaporator

G

Motorised valve

C

Compressors

H

Temperature sensor

D

MCHE condenser & MCHE Free Cooling coil

I

Flow rate controller

E

Dehumidifier filter

J

Vent valve

F

Electronic expansion valve

K

Filter

L

Manual valve

12 - OPTIONS

AQUACIAT

POWER

™ LD/ILD

EN-82