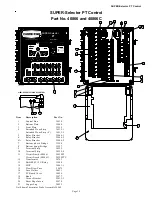

SUPER-Selector

‘

PT Control

Page 5

Control Sensor

The Control Sensor reads the temperature and determines which stage the control

is in.

When the master selector is pointed toward CONTROL SENSOR, the display window

will reflect which sensor is serving as the Control Sensor (any of the sensors may be

chosen as the CONTROL SENSOR). Use the edit switch to choose which sensor is to

be the Control Sensor.

One to eight sensors may be installed. Refer to the section titled "Telling the Control the

Number of Sensors Installed" on page 9. The positions used on the terminal strip must

be in numerical order (i.e. 1, 2, 3, not 1, 3, 6, etc.).

Room Temp

When the master selector switch points toward READ SENSOR, the display will show

the temperature reading of the sensor chosen. The reading cannot be edited by the edit

switch. It is a reading of the temperature at that sensor and is not subject to being edited.

Whenever any of the sensors fail, the alarm relay will be energized and the FAILED

SENSOR light will flash. Use the sensor selector knob to determine which sensor has

failed.

If the CONTROL SENSOR fails, the control will lock itself into the stage and

mode it is in at the moment the sensor failure occurs.

For instance, if the control is at set temp and in power ventilation with the exhaust fans

cycling on and off, and the CONTROL SENSOR fails, the control will continue

operating in that mode. Replacing the sensor, or simply changing the CONTROL

SENSOR to a good sensor position will return the control to automatic operation.

Set Point

The set point (desired temp) is edited when the master selector is pointing at the SET

POINT position. The set point can be set from 0.0 to 200.0

Stages: Temperatures & Offsets

When the master selector switch is pointed toward OFFSETS the edit switch will set the

temperature difference between the previous stage and the stage that is selected. For

instance, if the offset for stage 1 = 2.0, the offset for stage 2 = 3.0, and the offset for

stage 3 = 4.0, then the STAGE 3 absolute temperature will be Set Temp + 2.0 + 3.0 +

4.0. Changing a temperature difference will affect the absolute temperature of that stage

and all stages above that stage. It will not affect the absolute temperature of any stages

below that stage.

Heat Stage 1 and Heat Stage 2 behave in a similar manner except that they are heat

stages and are below the set temperature instead of above. The heat stages turn on at the

stage’s temperature when the temperature is falling and then off when the temperature

raises .3° from it’s turned on temperature.

The cool stages (stages 1 through 10) turn on at the stages temperature when the

temperature is rising and turn off at the previous stages temperature when the

temperature is falling.

Pointing the master selector switch to TEMPERATURES causes the display to indicate

CAUTION

The Control Sensor

must be located in the

bird or animal area

being controlled.