Chicago Pnematic Compressors

11/2008

62 305 549 65

Page 29

21.0 ROUTINE MAINTENANCE FOR TRAINED PERSONNEL

BEFORE CARRYING OUT ANY MAINTENANCE IT IS MANDATORY TO STOP THE COMPRESSOR AND

DISCONNECT IT FROM THE MAIN POWER.

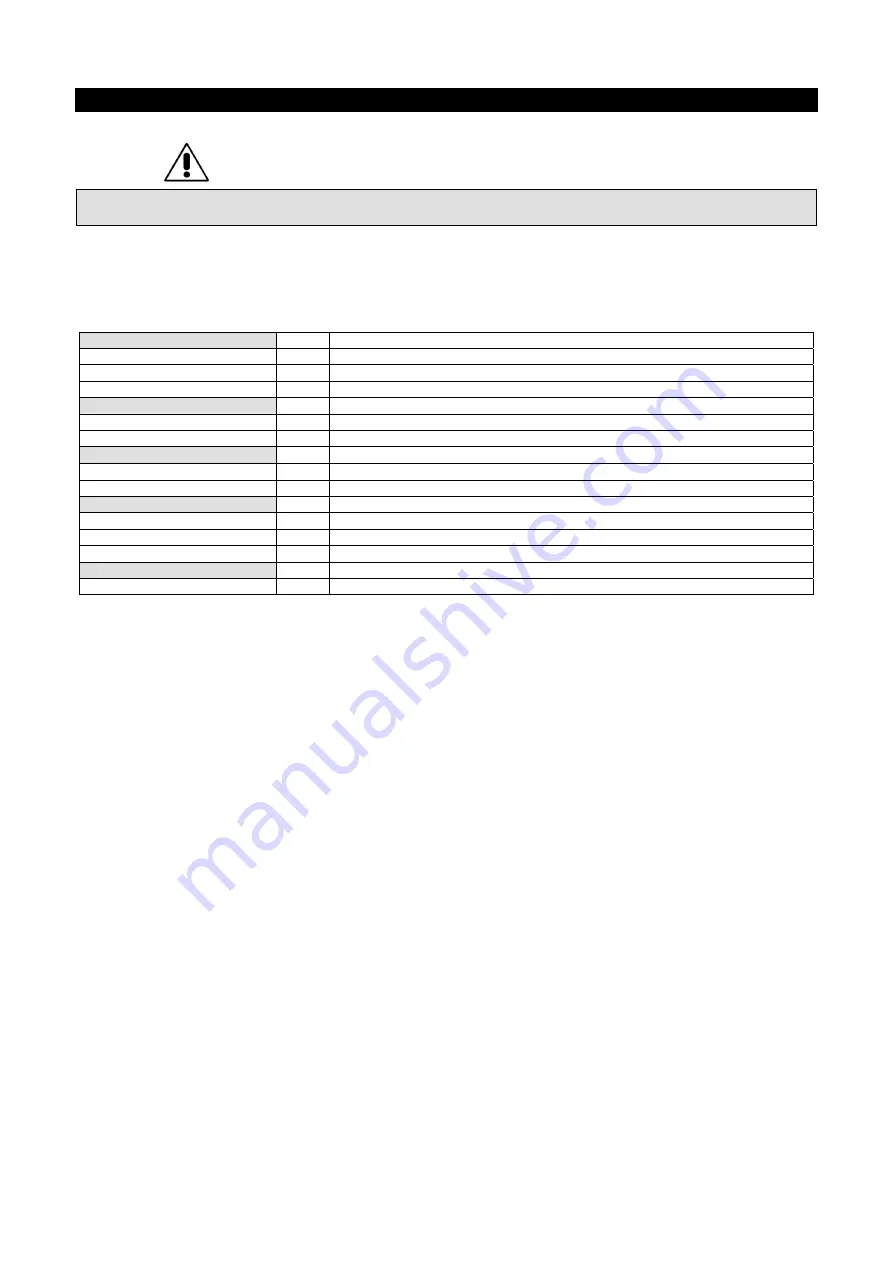

MAINTENANCE SCHEDULE

These maintenance intervals are recommended for work environments that are not dusty and are well ventilated. For

particularly dusty environments, double the frequency of maintenance.

Every 50 working hours

Drain condensate from the sump tank

Check the oil level

Clean the filter panel

Every 500 hours

Clean the air suction filter

(see controller LED)

Check belt tension

Every 2000 hours

Change the oil filter

(see controller LED)

Change the suction filter

(see controller LED)

Every 4000 hours

Clean the finned surface of the air-oil cooler

Change the oil separating filter

(see controller LED)

Change belt

Every 8000 hours

Change the oil

Maintenance overhaul on entire compressor

THE OPERATIONS MARKED

ARE DESCRIBED IN PART "A" OF THIS MANUAL ON SECTION 15.3

Содержание CPC 4

Страница 1: ...Instruction Manual EN CP COMPRESSOR Model CPC 40 50 60 62 305 549 65 CPC 50 ...

Страница 34: ...11 2008 Chicago Pneumatic Compressors Page 34 62 305 549 65 NOTE ...

Страница 35: ...Chicago Pnematic Compressors 11 2008 62 305 549 65 Page 35 NOTE ...

Страница 36: ...support support CPcompressor com 1 877 861 CPAC CP Compressors 1800 Overview Dr Rock Hill SC 29730 ...