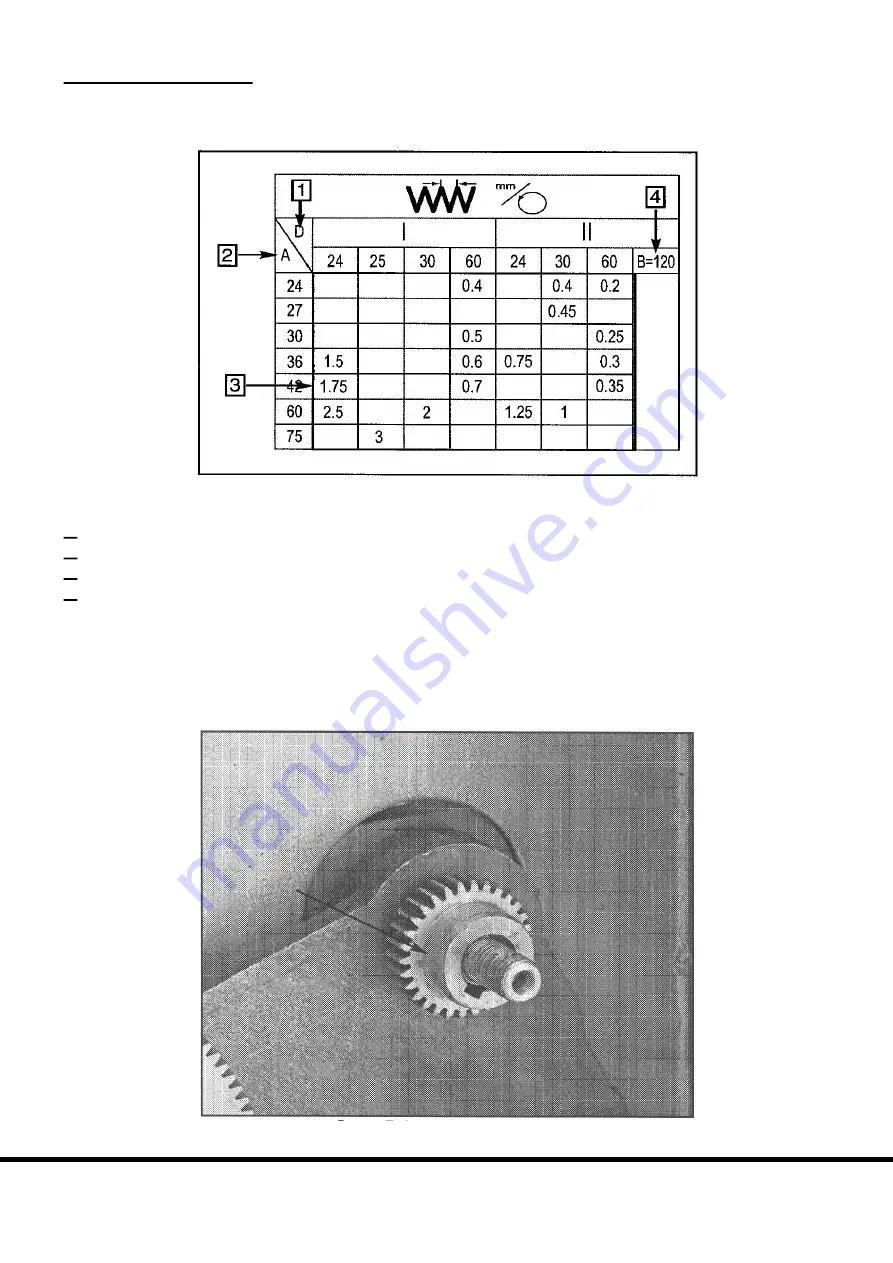

METRIC THREADING

The metric threading gear chart is illustrated in

Figure 51

. The layout is listed below to help identify

gears for cutting threads with metric pitches. The chart below lists threads in millimetres or the theoretical

amount of space one thread occupies.

Figure 51

. Rates given in millimetres and inches.

Please note that charts reflect approximate apron movement per revolution.

1.

The column of numbers below D represent the number of teeth on gears used in position D.

2.

The numbers to the right of A represent the number of teeth on gears used in position A.

3.

Field of possible thread pitches.

4.

This gear will always have 120 teeth and will be intermediate to gears A and D.

Example:

To cut a thread with a pitch of 0.5mm we would select a 60 tooth gear and place it in the A position; we

would select a 30 tooth gear and place it in the D position and we would use the 60/120 combination gear.

However, you will need to place the gears in position A and D so that they both contact gear B only. You

can accomplish this by turning gear D so the hub is on the outside as in

Figure 52.

Figure 52

. Gear D is turned so hub is on outside.

Chester UK Model B

31