DRILL PRESS CONTROLS

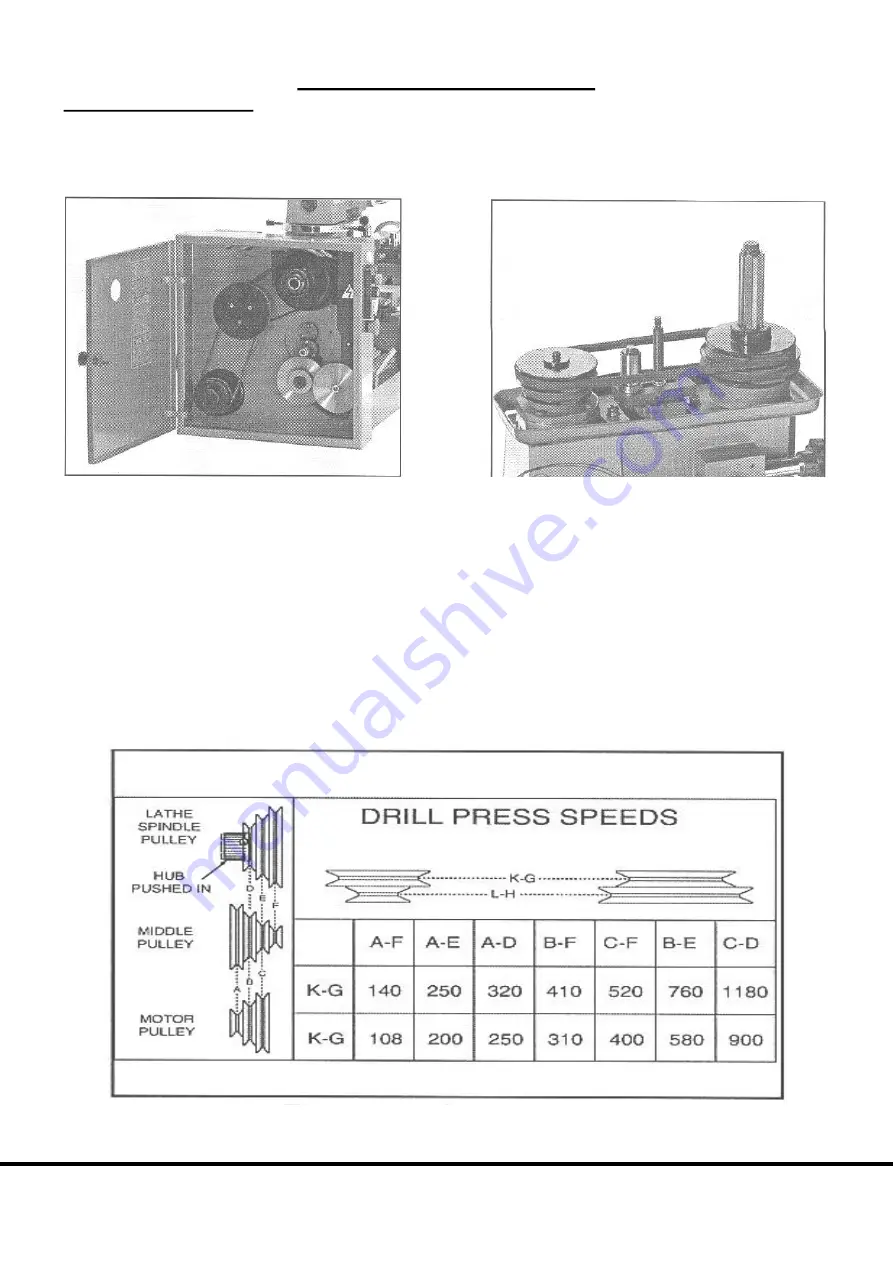

DRILL PRESS SPEEDS

The speed of the drill press spindle is controlled by 2 groups of belts and pulleys. The belt positions on

the end of the lathe control one speed range.

See Figure 25.

The belts and pulleys above the drill press

control the other range.

See Figure 26.

Figure 25.

Lower pulleys for speed changes

Figure 26.

Upper pulleys for speed changes

Unplug the Lathe/Mill!

Before using the drill press, the hub at the end of the lathe spindle must be

adjusted to the “in” position.

See Figure 27.

To ease engagement of this hub, slowly rotate the drill

spindle by hand while applying pressure to the hub.

The chart also shows the various combinations of belt positions for achieving a desired speed.

Example:

To select a spindle speed of 310 R.P.M., start by moving the belts at the end of the lathe. Move the lower

belt to the “B” position. Move the upper belt to the “F” position. Follow the belt changing procedures in

the section titled

Lathe Speeds.

Next, move the belt located above the drill press to the “KG” position.

Figure 27.

Speed chart.

Chester UK Model B

18