14

MB Pool & spa heater

VENTILATION REQUIREMENTS

The heater must have both ventilation and combus-

tion air. Safe and effi cient operation of the heater is

vitally dependant upon a good supply of fresh air to

the room in which the appliance is installed. Minimum

requirements for net free air supply openings direct

to outside air at both high and low level are detailed

in the table at the bottom of this page.

Position grilles to avoid the risk of accidental block-

age or fl ooding. Further guidance is given in BS6644.

CAUTION:

Combustion air must not be contaminat-

ed by corrosive chemical fumes which can damage

the heater and void the warranty.

NOTE:

The design is also certifi ed by Advatica

for indoor installation when fi tted with appropriate

manufacturer's draught diverter and a suitable fl ue

system to outside. The heater must be in a room

separated from living rooms and provided with

appropriate ventilation direct to outside. It must not

be installed in a cupboard or compartment which is

directly connected to a living space.

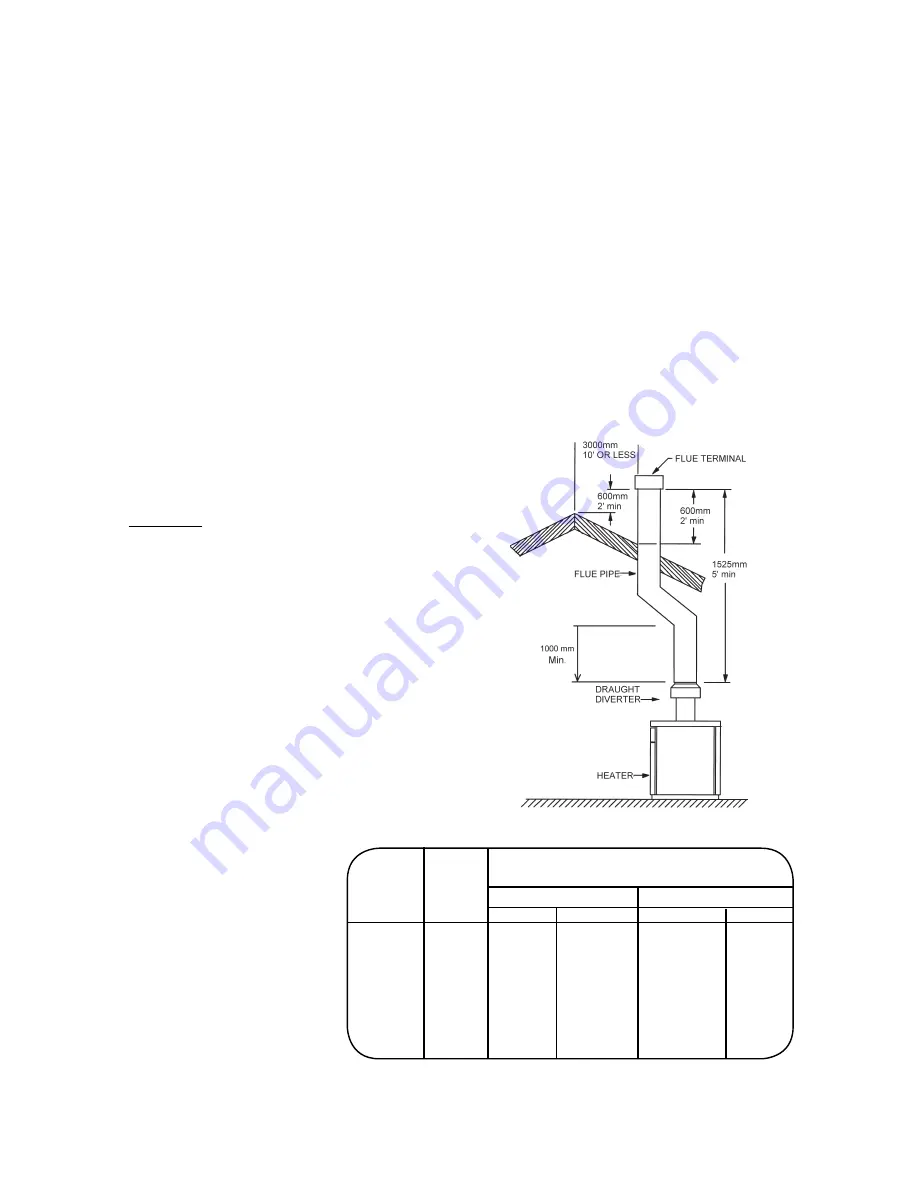

FLUE SYSTEM

WARNING:

Indoor boilers require a draught diverter that must

be connected to a fl ue pipe and properly fl ued to the

outside. Failure to follow this procedure can cause

fi re or fatal carbon monoxide poisoning.

To ensure safe and satisfactory operation of the heat-

er, the fl ue system must be capable of the complete

evacuation of fl ue products at all times. The effective

height of the fl ue terminal above the draught diverter

must ensure suffi cient buoyancy to overcome the re-

sistance of the bends and horizontal runs of the fl ue

pipe. The number of bends and length of horizontal

run must be kept to a minimum to reduce resistance.

The chimney must terminate in a downdraught free

zone.

The fl ue/chimney design should avoid the formation

of excessive quantities of condensate and for this

reason it is recommended that all chimneys are suit-

ably insulated and lined.

The draught diverter supplied with the heater must

be used.

Drain points should be fi tted at the bottom of all ver-

tical fl ue sections. Drain pipes must be a minimum

of 25mm (1 in) internal diameter and manufactured

from acid condensate resistant material (eg stainless

steel) and positioned so that pipe runs and discharge

points are not subject to the effects of frost and that

fl ue gases cannot leak into the room.

Any terminal fi tted must be of a type acceptable to

British Gas plc.

As part of commissioning, the fl ue must be satisfac-

tory when tested for fl ue fl ow and spillage as detailed

in BS5440 Part 1.

Flue.pcx

Model

Input Plant Room (cm

²

)

ref. BS5440 for models under 70kW

(kW)

Inside

Outside

High Low

High

Low

055

13

117 234

59

117

105

27 243 486

122

243

155

39

351 702

176

351

185

50

450 900

225

450

265

72

-

-

297

600

405

108

-

-

378

756

ref. BS6644 for models over 70kW

Compliance with the recom-

mendations made in BS 6644;

British Gas publication IM11

"Flues for Commercial and

Industrial Gas fi red boilers and

air heaters" and the "Third Edi-

tion of the 1956 Clean Air Act

memorandum" should be strictly

observed where applicable.