8

27

All the broach cutters allow automatic cooling by means of the SR5000 unit supplied with

the drills.

3.7) BROACH CUTTERS

These cutters rapidly produce high quality, accurate

holes in a single pass. The automatic lubrocooling

system reduces friction and eliminates heat build up

during the drilling operation. Under standard conditions

a broach cutter can drill 40-50 holes, depending on

the hardness of the rail.

15128

15130

15132

15234

TSC 1 1/8"

15138

TSC 1 1/4"

TSC 1 5/16"

15144

15146

TSC 1 1/2"

TSC 3/4"

01354

01355

01356

01357

01358

01359

01360

01361

01362

01363

01364

12218

3-12224

3-12226

3-12228

3-12230

3-12232

3-12236

BROACH

CUTTER

PILOT

BIT

HOLE

DIAME-

TER

(inches)

7/8"

15/16"

1"

1 1/16"

1 1/8"

1 3/16"

1 1/4"

1 5/16"

1 3/8"

1 7/16"

1 1/2"

3/4"

7/8"

15/16“

1“

1 1/16"

1 1/8"

1 3/16“

1 1/4"

1 5/16“

1 3/8"

1 7/16"

1 1/2"

9/16"

3/4"

13/16"

7/8"

15/16"

1"

1 1/8"

MAX.

DEPTH OF CUT

(inches)

Ref. PPC 2

Ref. PPL 2

3-10528

2 "

7/8 "

3 "

APPENDIX “A”

Factors which infl uence the number of holes that can be made according to the

tool used.

– Hardness of the material to be drilled.

– Thickness to be drilled.

– Stability of the drill clamp and correct assembly of the cutter/bit.

– Suitable lubrocooling (lubrication/cooling) to keep the temperature of the tool low so

as not to compromise the effi ciency of the cutting edges, whilst at the same time facilitating

the removal of the swarf.

– Contact time of the cutting edges of the cutter/bit with the material to be drilled;

bear in mind that the faster the hole is made the greater the effi ciency.

– Observance:

1) Commence drilling by exerting light pressure on the advancing lever, progres-

sively increasing and then relaxing it when the tool is in the exit phase.

2) Avoid pressure jolts and only advance according to the drilling diameter to avoid scratch-

ing the material or damaging the cutting edges of the cutter/bit.

3) Remember that a tool with effi cient cutting edges requires a pressure lower than that

applied to one with which a certain number of holes have already been made.

4) When holes are made close to raised lettering on the rails, commence drilling

with very light pressure until the lettering disappears, to avoid possible breakage of the

tool.

5) Bear in mind that when operating on very hard rails, as in the case of quality 1100 steel,

it is advisable to increase the lubrocoolant fl ow rate.

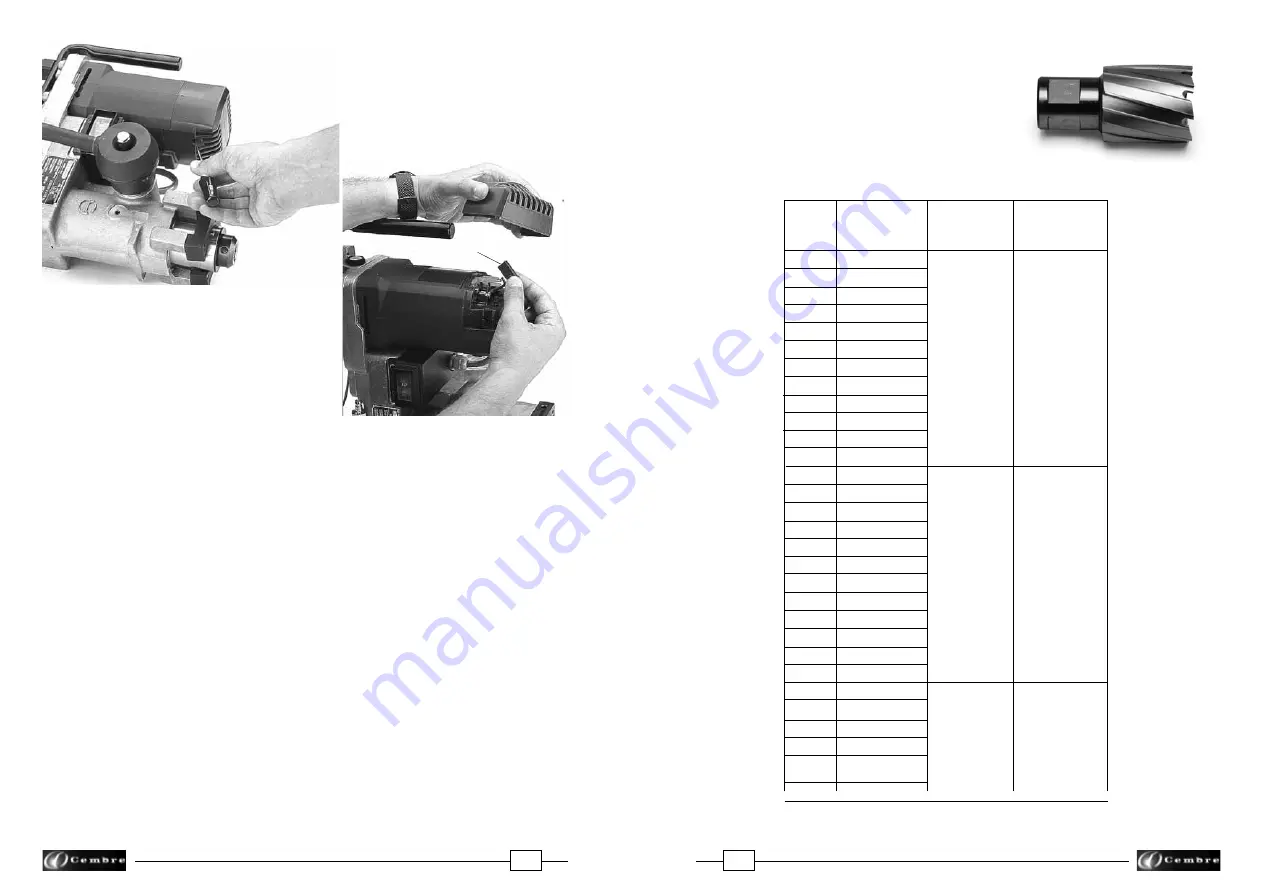

FIG. 26 – CHANGING THE BRUSHES

Brush