8

ENGLISH

3.4) Storage

After completion of the work

release the oil pressure

by pressing the release push button and

make sure that the ram of the head connected is completely retracted.

– Switch off the pump by the ON-OFF switch (IG), selecting position "

0

".

– Disconnect the pump from the mains supply for long periods of inactivity.

4. WARNING

The pump is robust, completely sealed and requires very little daily maintenance.

Compliance with the following points should help to maintain the optimum performance of the unit:

– Avoid dirty surfaces: dust and sand are a danger to any hydraulic equipment.

– The mains supply cable must be in perfect conditions and correctly installed other it must be

replaced

immediately.

Should it be necessary to extended the mains cable, use 3 core (2 earth) cable of suitable

section.

Never pull the cable to disconnect it from the mains supply.

Keep the cable may from heat, oil and sharp edges.

– Store the pump in a clean, dry environment.

4.1) Flexible hose

The fl exible hose is designed for high-pressure operation and should not be tightly bent, knotted,

kinked or squashed.

Take care when storing the pump, the hose should be coiled in wide loops.

High pressure fl exible hoses are subject to a natural ageing process which can result in a reduc-

tion in performance potentially aff ecting safety of the operator. As a result their life span is limited.

In order to ensure safe use of their units,

Cembre

recommends replacing the hose within 10 years

from the date printed on the fi ttings.

Before using the pump always check the integrity of the fl exible hose and the quick couplers

making sure there are no abrasions, cuts, deformations or swellings.

5. MAINTENANCE

Never open the electrical panel cover or eff ect any maintenance operation when the pump is

connected to the mains supply.

Should replacement of pump components be necessary, always use original spare parts.

After every use, the pump and accessories must be wiped with a clean cloth, taking care to remove

any residue, especially around the sockets, quick couplers and inside the protective caps.

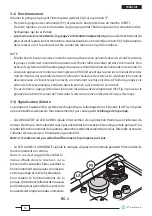

It is possible to check working pressure with the MPC1 gauge available as an optional accessory

(see page 38).

Содержание CPE-1

Страница 4: ...4 IM FIG 1 PUMP POMPE PUMPE BOMBA POMPA IR TF CA MT QE PO LA C IG PS F PF PC...

Страница 37: ...37 FIG 6 TL FIG 7 TV...

Страница 38: ...38 C2 C1 SE R RC RL TR PR EV FIG 8...