8

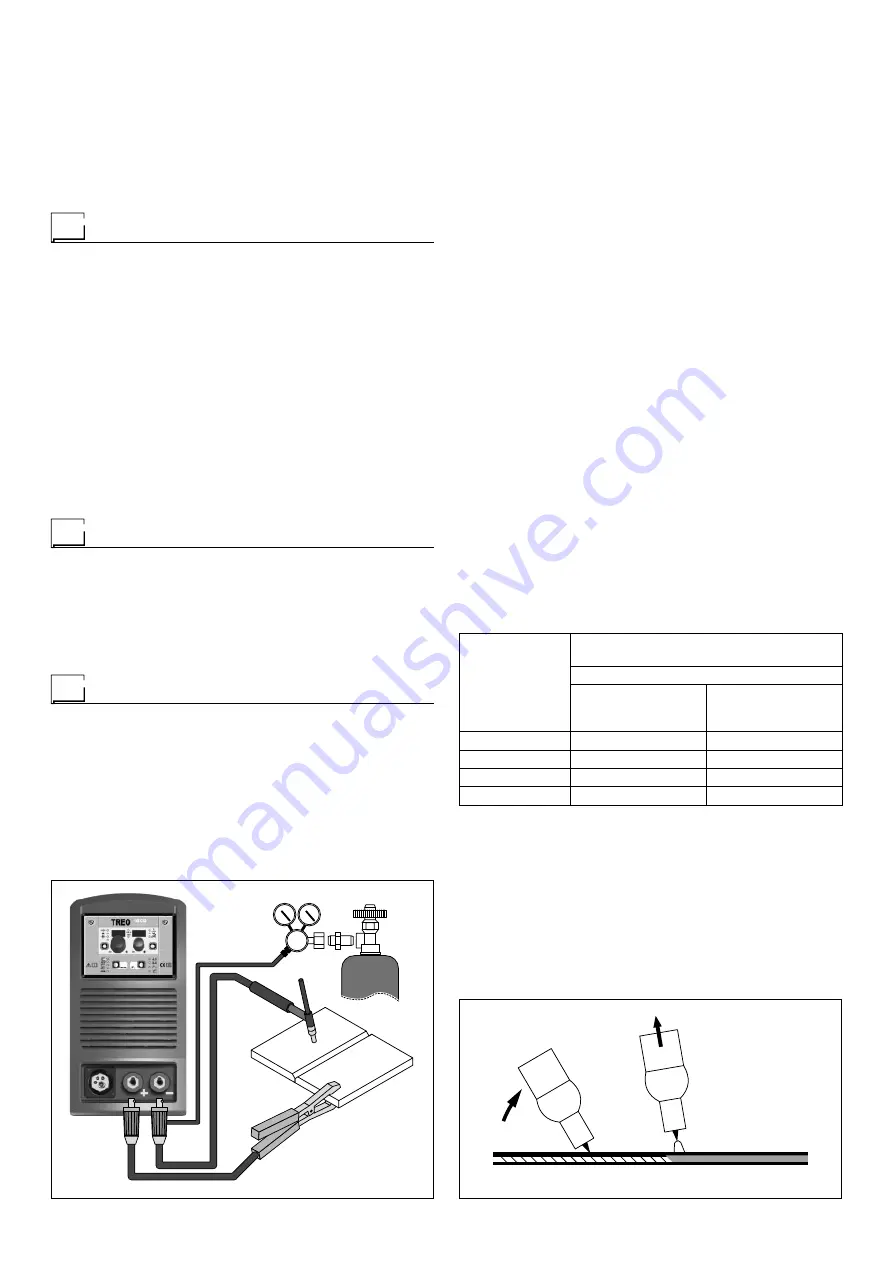

FIG. F

To begin spot welding:

• Place the gas guiding nozzle perpendicular on the workpiece

to be spot welded.

• Press the torch button to start the welding current and wire

feed.

• When the spot welding time expires (SPOT WELD TIME),

the wire feed stops automatically.

• When the torch button is pushed again a new welding cy-

cle starts.

• Release the torch button.

Interval welding (Stitch)

The substantial differences with the spot welding mainly con-

cern the adjustments that must be carried on the welding ma-

chine.

Use the control panel to select the interval welding mode and

then make the changes to the related “Special functions - Fx”

(for further information see the TX control panel manual), which

allows the machine to do this specific type of welding.

To begin interval welding:

• Press the torch button to start the welding current and wire

feed.

• At this point the welding machine automatically carries out

a succession of welded portions (STITCH WELD TIME) fol-

lowed by a pause (STITCH WELD PAUSE), according to the

times entered previously. This procedure stops automatically

only when the TORCH BUTTON is released.

• When the torch button is pushed again the torch begins a

new interval welding cycle.

Aluminium welding

To weld with aluminum wire proceed as follows:

• Replace the drive roller with the appropriate for aluminum

wire.

• Use a torch with a 3m cable and a carbon Teflon sheath.

• Set the pressure between the drive rollers at the minimum,

by turning the screw provided.

• Use argon gas at a pressure of 1,3 - 1,7 bar.

TIG welding with “Lift”

In the TIG process welding is achieved by melting the two metal

pieces to be joined, with the possible addition of material from

the outside, using an arc ignited by a tungsten electrode. The

“Lift” (TCS) type ignition used in TREO equipments makes it

possible to reduce tungsten inclusions on ignition to a mini-

mum. The molten bath and the electrode are protected by and

inert gas (for example, Argon). This type of welding is used

to weld thin sheet metal or when elevated quality is required.

1) Connecting the welding cables (Fig. F):

• Connect one end of the gas hose to the gas connecter on

the TIG torch and the other end to the pressure reducer

on the inert gas cylinder (Argon or similar).

• With the machine switched off:

- Connect the ground cable to the snap-on connector

(positive).

- Connect the relative ground clamp to the workpiece or

to the workpiece support in an area free of rust, paint,

grease, etc..

- Connect the TIG torch power cable to the snap-on con-

nector marked - (negative).

2) Switch the welding machine on by moving the power sup-

ply switch to

I

(Pos. 5, Fig. A).

3) Make the adjustments and do the parameter settings on

the control panel (for further information see the TX con-

trol panel manual).

4) Open the gas cylinder and regulate the flow by adjusting

the valve on the TIG torch by hand.

5) Ignite the electric arc by contact, using a decisive, quick

movement without dragging the tungsten electrode on the

piece to be welded (“Lift” type ignition - Fig. G).

6) The welder has a SWS “Smart Welding Stop” system for

the end of TIG welding. Lifting up the torch without switch-

ing off the arc will introduce a slope down and it will switch

off automatically.

7) When you have finished welding remember to shut the

valve on the gas cylinder.

Table 3 shows the currents to use with the respective elec-

trodes for TIG DC welding. This input is not absolute but is for

your guidance only; read the electrode manufacturers’ instruc-

tions for a specific choice. The diameter of the electrode to use

is directly proportional to the current being used for welding.

Table 3

Ø ELECTRODE

(mm)

ELECTRODE TYPE

Current adjustment field (A)

TIG DC

Tungsten

Ce 1%

Grey

Tungsten

Rare ground 2%

Turchoise

1

10-50

10-50

1,6

50-80

50-80

2,4

80-150

80-150

3,2

150-250

150-250

FIG. G

2000HA86

Содержание TREO 1800 Synergic MIG-MAG

Страница 12: ...12 Electro topographical diagram 2101AB10...

Страница 14: ......

Страница 22: ......

Страница 42: ......