21

207

2065949

Slide support

4

232

3005249

O seal ring 16*2.4

2

208

6000236

Circlip

4

233

2012001

Piston

2

209

6000135

Flat washer12*20*2

4

234

3005250

O ring75*5.7

4

210

2065932

Washer

4

235

6000144

Nut M12

2

211

2053201

Sleeve

4

236

2017901

Cylinder barrel

2

212

6000213

Spring washer 12

4

237

2067409

Screw M6

8

213

6000449

Screw M12*95

1

238

2045901

Clamping rear cover

2

214

6000196

Circlip 70

1

239

3005075

Union IPB6-01

2

215

2065947

Slide plate

2

250

2064376

Complete plate

1

220

2017801

Complete clamping

cylinder

2

251

2065928

Plate

2

221

6000178

Circlip 30

2

252

2065931

Plastic sleeve

1

222

6000140

Flat

washer22*29*0.5

2

253

6000112

Screw M6*12

4

223

3005074

UnionIPL6-01

2

254

2065950

Rod

4

224

3005157

Y seal

2

255

2065930

Shaft

4

225

2018001

Piston rod

2

256

6000233

Nut M6

4

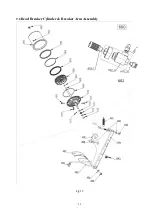

2053301 Parts of Rotating Valve Assembly

(

Fig.36

)

300

2053301

Complete

rotating

valve

1

303

3004601

O-seal 59.5*3.1

3

301

2010901

Rotating valve core

1

304

2011001

Rotating valve casing

1

302

3005004

Union IPC6-01

4

305

6000356

Screw M3*5

4

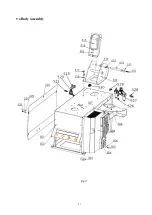

2064938 Parts of Gearbox Assembly (Fig. 36)

306

2064938

Complete gearbox

1

320

6000148

Nut M8

5

307

3000801

Oil ruler

1

321

2064158

Oil seal cover

1

308

3000901

Oil ruler casing

1

322

3004501

O seal 35*3.1

1

309

6000121

Screw M8x30

5

323

6000168

Bearing 30205

2

310

2009201

Upper cover

1

324

2009601

Worm screw

1

311

6000166

Bearing 6010

1

325

6000337

Key 6*6*20

1

312

2009401

Gearbox shaft

1

326

3005127

Seal 25*40*8

1

313

6000102

Screw M8x20

1

327

6000170

Key12*8*50

1

314

6000199

Washer 8

1

328

6000112

Screw M6*12

1

315

2037201

Washer

1

329

6000101

A-key12*8*40

1

316

2009701

Pulley

1

330

6000204

Pin 8*16

1

317

2009501

Worm Gear

1

331

6000200

Washer 10*30*2

6

318

6000167

Bearing 6208

1

332

6000181

Screw M10*160

6

Содержание CASC506

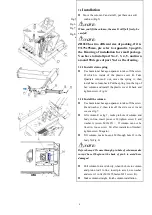

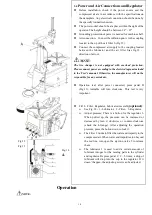

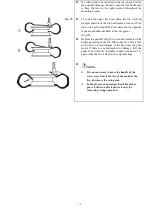

Страница 14: ...13 Fig 21 Fig 22 Fig 23...

Страница 25: ...24 9 Exploded drawings 9 1 Column assembly Fig 34...

Страница 26: ...25 9 2 Turntable assembly Fig 35...

Страница 27: ...26 9 3 Gearbox motor assembly Fig 36...

Страница 28: ...27 9 4 Body assembly Fig 37...

Страница 29: ...28 9 5 Pedal Assembly Fig 38...

Страница 30: ...29 9 6 Bead Breaker Cylinder Breaker Arm Assembly Fig 39...

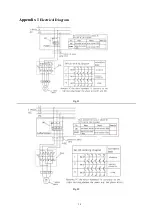

Страница 31: ...30 Appendix 1 Electrical Diagram Fig 41 Fig 42...

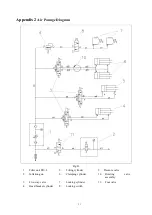

Страница 33: ...32 Appendix 3 Drawing of installation for small package Fig 44...

Страница 38: ...37 10 8 Exploded drawings...

Страница 50: ......