12

Fig.17

Fig.18

Fig.19

Fig.20

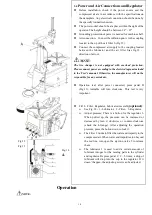

⚫

Place the tire between the bead breaker shoe

and rubber pad and keep the shoe between the

bead and rim, about 1cm to the bead

(Fig.17-a). Depress pedal C (Fig.17-b) to

separate the tire from rim.

⚫

Repeat the above steps on other part of the tire

to get the tire separated thoroughly from the

rim.

NOTE

:

When using the bead breaking arm, do not put

arms and hands between the tire and the bead

breaker

⚫

Press switch handle button N (Fig. 18), fix arm.

⚫

Press pedal A, tilt the column.

⚫

Place the wheel on the turntable. Depress pedal

B, For the asymmetric deep groove rim, keep

the narrow rim upward

(

Fig. 19

)

.

⚫

NOTE

:

Different types of clamping can be

chosen in accordance with different rims.

➢

In case of inward clamping, shrink the jaws

together, place the wheel on the turntable and

depress pedal B to clamp (Fig.20-a).

➢

In case of outward clamping, enlarge the jaws

outward (2-3cm away from periphery of the

rim) and place the wheel on the turntable. Press

down the rise/fall control lever to keep the rim

close to the jaws, and depress pedal B to clamp

it(as fig.20-b

)

.

Содержание CASC506

Страница 14: ...13 Fig 21 Fig 22 Fig 23...

Страница 25: ...24 9 Exploded drawings 9 1 Column assembly Fig 34...

Страница 26: ...25 9 2 Turntable assembly Fig 35...

Страница 27: ...26 9 3 Gearbox motor assembly Fig 36...

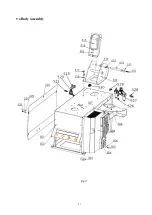

Страница 28: ...27 9 4 Body assembly Fig 37...

Страница 29: ...28 9 5 Pedal Assembly Fig 38...

Страница 30: ...29 9 6 Bead Breaker Cylinder Breaker Arm Assembly Fig 39...

Страница 31: ...30 Appendix 1 Electrical Diagram Fig 41 Fig 42...

Страница 33: ...32 Appendix 3 Drawing of installation for small package Fig 44...

Страница 38: ...37 10 8 Exploded drawings...

Страница 50: ......