19

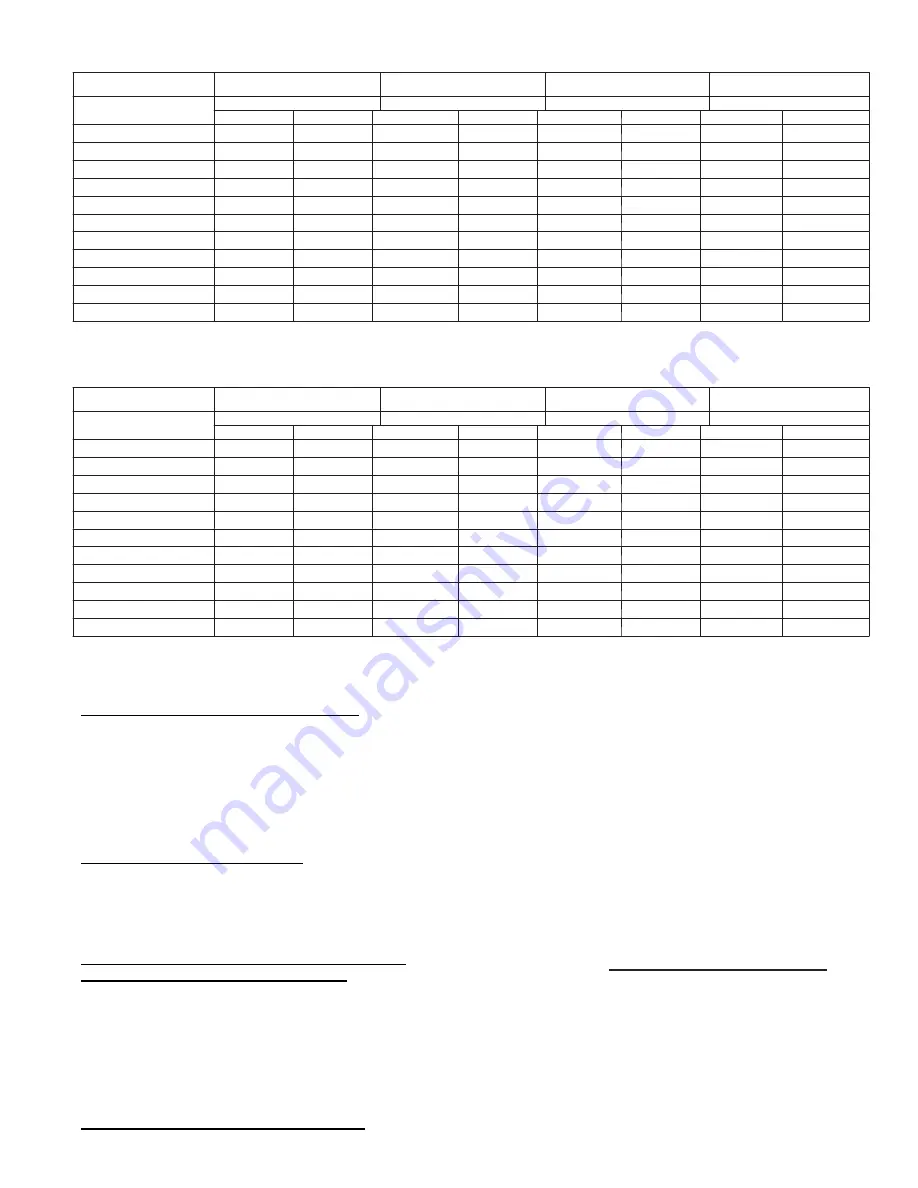

Table 5—Natural Gas

NOMINAL INPUT

200,000

175,000

150,000

125,000

Altitude

Vent Lengths

Vent Lengths

Vent Lengths

Vent Lengths

Min

Max

Min

Max

Min

Max

Min

Max

0

200,000

200,000

175,000

175,000

150,000

150,000

125,000

125,000

1,000

197,000

196,500

172,400

172,200

147,800

147,400

123,500

123,000

2,000

194,000

193,000

169,800

169,400

145,600

144,800

122,000

121,000

3,000

191,000

189,500

167,200

166,600

143,400

142,200

120,500

119,000

4,000

188,000

186,000

164,600

163,800

141,200

139,600

119,000

117,000

5,000

185,000

182,500

162,000

161,000

139,000

137,000

117,500

115,000

6,000

182,000

179,000

159,400

158,200

136,800

134,400

116,000

113,000

7,000

179,000

175,500

156,800

155,400

134,600

131,800

114,500

111,000

8,000

176,000

172,000

154,200

152,600

132,400

129,200

113,000

109,000

9,000

173,000

168,500

151,600

149,800

130,200

126,600

111,500

107,000

10,000

170,000

165,000

149,000

147,000

128,000

124,000

110,000

105,000

Table 6—LP Gas

NOMINAL INPUT

200,000

175,000

150,000

125,000

Altitude

Vent Lengths

Vent Lengths

Vent Lengths

Vent Lengths

Min

Max

Min

Max

Min

Max

Min

Max

0

200,000

200,000

175,000

175,000

150,000

150,000

125,000

125,000

1,000

195,900

195,750

171,900

171,200

146,900

146,700

123,050

122,250

2,000

191,800

191,500

168,800

167,400

143,800

143,400

121,100

119,500

3,000

187,700

187,250

165,700

163,600

140,700

140,100

119,150

116,750

4,000

183,600

183,000

162,600

159,800

137,600

136,800

117,200

114,000

5,000

179,500

178,750

159,500

156,000

134,500

133,500

115,250

111,250

6,000

175,400

174,500

156,400

152,200

131,400

130,200

113,300

108,500

7,000

171,300

170,250

153,300

148,400

128,300

126,900

111,350

105,750

8,000

167,200

166,000

150,200

144,600

125,200

123,600

109,400

103,000

9,000

163,100

161,750

147,100

140,800

122,100

120,300

107,450

100,250

10,000

159,000

157,500

144,000

137,000

119,000

117,000

105,500

97,500

NOTE: The boiler automatically derates input as altitude increases. No alterations to boiler are required for altitudes above sea level.

These low pressure gas---fired hot water boilers are design certified by CSA International, for use with natural and propane gases. The boilers are constructed

and hydrostatically tested for a maximum working pressure of 50 psig (pounds per square inch gauge) in accordance with A.S.M.E. (American Society of

Mechanical Engineers) Boiler and Pressure Vessel Code Section IV Standards for heating boilers.

TEST HIGH LIMIT CONTROL AND ADJUST

While burner is operating, Adjust setting on high limit control

below actual boiler water temperature. Burner should go off while

circulator continues to operate. Raise limit setting above boiler

water temperature and burner should reignite after pre purge and

igniter warm--up period. Set the high limit control to the design

temperature requirements of the system. Maximum high limit

setting is 200

_

F. Minimum high limit setting is 100

_

F. Return

high limit differential to original setting of 20

_

F.

TEST OTHER SAFETY CONTROLS

If the boiler is equipped with a low water cut off, a manual reset

high limit, or additional safety controls, test for operation as

outlined by the control manufacturer. Burner should be operating

and should go off when controls are tested. When safety controls

are restored, burner should reignite.

SET THERMOSTAT HEAT ANTICIPATOR (IF USED)

AND VERIFY THERMOSTAT OPERATION

For a single thermostat connected to the yellow thermostat lead

wires in the furnished field wiring junction box, the heat

anticipator should be set at 0.7 amps. For other wiring

configurations, refer to the instructions provided by the

thermostat manufacturer regarding adjustment of heat anticipator.

Cycle boiler with thermostat. Raise the thermostat to the highest

setting and verify boiler goes through normal start up cycle.

Lower thermostat to lowest setting and verify boiler goes off.

MEASURE THE NATURAL GAS INPUT RATE

Correct input rate is essential for proper and efficient operation of

the burner and boiler.

1. Determine elevation at installation site.

2. See Table 5 and 6 to determine the correct approximate

input rate for the local elevation.

3. Obtain the yearly average heating value of the local gas

supply from the gas utility. At sea level elevation, it should

be approximately 1000 Btu’s per standard cubic foot.

4. Operate boiler for 5 minutes.

5. Turn off all other gas appliances, extinguishing standing

pilots where applicable.

6. At gas meter, measure time in seconds required to use one

cubic foot of gas.

7. Calculate “input rate” according to the following formula:

Btuh input rate = 3600 x heating value from step 3

time from step 6

8. The measured input rate should be /--2 percent of

the input rating from step 2. If not, see the

ADJUSTMENTS section.