25

ADDING NEW LOCAL SCHEDULES

NOTE: Local schedules will only be effective if the unit occupan

-

cy control is configured for local schedule. See Tech Setup screen

for configuration options.

1. Click on the

button next to Add Schedule to add a new

schedule.

2. Choose On Schedule (Occupied) or Off Schedule (Unoccu

-

pied).

3. Choose Schedule Priority Type: Normal or Override.

4. Choose Schedule Type: Dated, Weekly, or Continuous.

5. Determine Start and End Time and Date of Schedule.

6. Save the schedule. The system uploads the schedule to the

controller.

ADDING MULTIPLE PERIODS TO A SCHEDULE

A weekly schedule can have multiple periods. For example, the

first period could be every Monday through Friday, 8:00 am to

5:00 pm. The second periods could be every Monday through

Wednesday 6:00 pm to 8:00 pm. You can create up to 4 period for

a day, and up to 28 periods for a week.

1. Create a weekly schedule for the first period. See Adding

New Local Schedule.

2. In the Schedules screen, touch the green bar for the schedule

to which a period should be added.

3. In the Schedule (day View) screen, touch the schedule name

or green bar (not the Effective Schedule bar) and press Next.

4. Press +Period.

5. Set the times and days for the new period; for example, Mon

-

day through Wednesday, 6:00 pm to 8:00 pm.

6. Save the period.

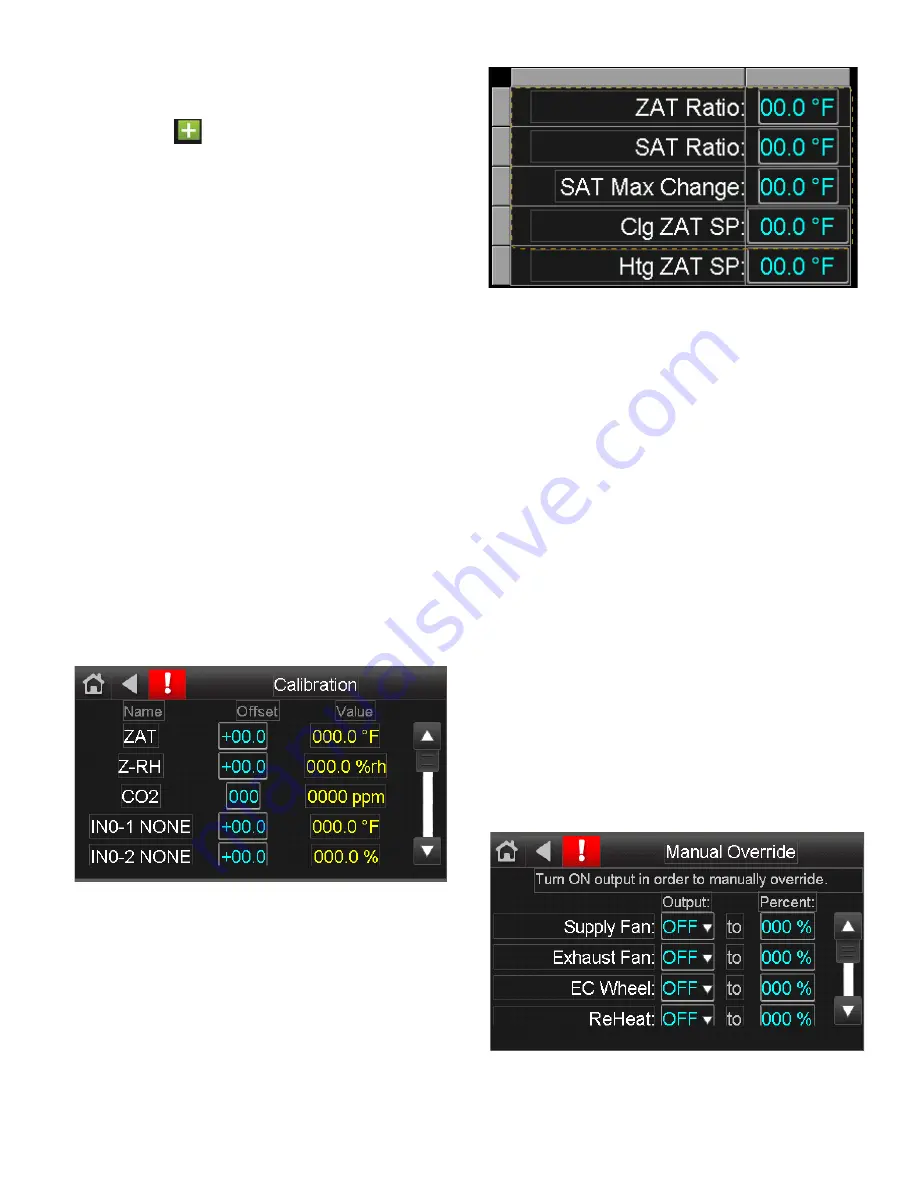

Sensor Calibration

The Sensor Calibration screen (

Home

Setup

Calibration

) dis

-

plays the calibration settings for unit sensors. See Fig. 35.

Fig. 35 — Calibration

The calibration screen can be used to adjust the effective sensor

reading by a fixed off set (+ or -) if the unit sensor reading is dif

-

ferent from a known reading source. Applying offsets can also be

useful for unit troubleshooting to influence unit operation (force

the unit into a mode) or to quickly determine a faulty sensor.

Faulty temperature sensors will typically display a value of –60°F

(open) or 296°F (short).

SUPPLY AIR TEMPERATURE (SAT) RESET

The SAT reset screen (

Home

Setup

Calibration

) displays the

set points for SAT reset operation. See Fig. 36.

Fig. 36 — SAT Reset Set Points

The SAT reset functions operates based on user configured set

points and a referenced temperature. See the Tech Settings screen

(

Home

Setup

Tech Setup

) to set and select the method of op

-

eration.

• ZAT/OAT Ratio - ratio that the ZAT/OAT deviation from

set point has on the SAT

• SAT Ratio - ratio that the SAT is reset based on the ZAT

ratio

• SAT Max Change - maximum reset amount

• Clg ZAT/OAT SP - zone air temp or outdoor air temp set

point for cooling operation

• Htg ZAT/OAT SP - zone air temp or outdoor air temp set

point for heating operation

SAT RESET OPERATION

When SAT reset is enabled, the unit is in the appropriate mode

based on the configuration (cooling, heating, or dehum), and the

zone air temp is above or below the zone air temp set point, SAT

reset is activated. The supply air temperature set point is reset by

the SAT ratio based on the ZAT deviation from ZAT set point and

the ZAT ratio.

Based on the settings in Fig. 36, if the unit was configured for SAT

Reset - ZAT CLG and the zone air temp 72°F (2°F above the cool

-

ing ZAT set point of 70°F), the unit would enter SAT reset mode.

Since the SAT ratio is 3°F SAT for every 1°F ZAT, the SAT would

be reset down by 6°F, up to a maximum of 10°F.

Manual Override

The Manual Override screen (

Home

Setup

Man Ovrd

) dis

-

plays the settings for overriding modulating components. See

Fig. 37.

Fig. 37 — SAT Reset Set Points

The Manual Override screen can be used to override the modula

-

tion for a component when the component is operating. Manual

overrides can be useful for troubleshooting or for unit start-up. It's